Remote fault monitoring and diagnosis system of belt conveyor based on Internet-of-Things technology

A technology of belt conveyor and Internet of Things technology, which is applied in the field of belt conveyor fault monitoring and diagnosis system, can solve the problems of inability to predict and predict fault information, high misjudgment rate and high cost, so as to reduce the operation and cost of enterprises. The effect of maintenance cost, reduction in the number of accidents, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

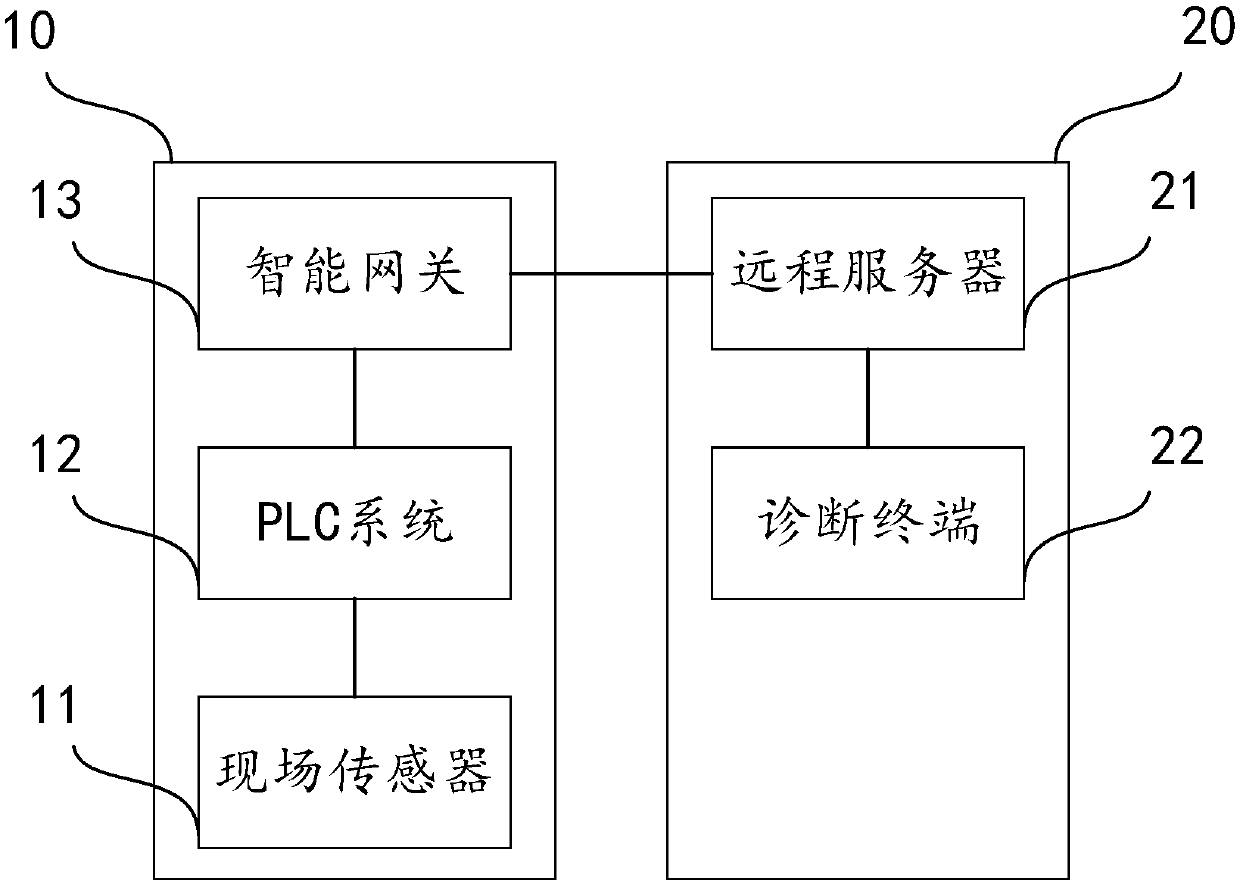

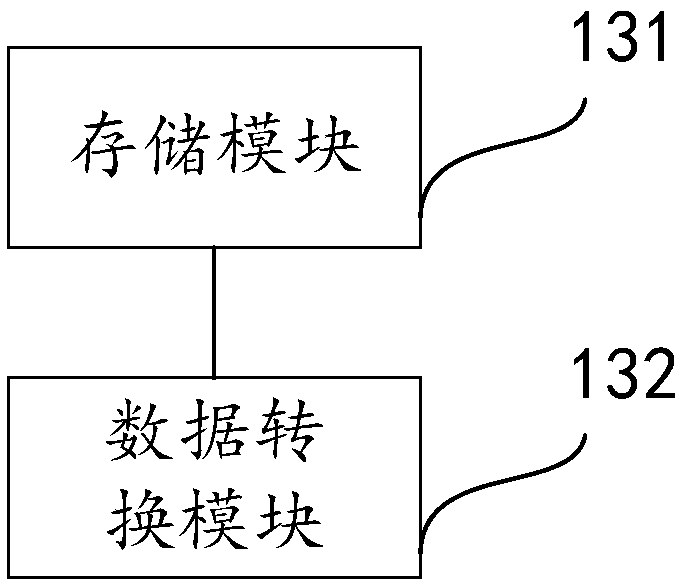

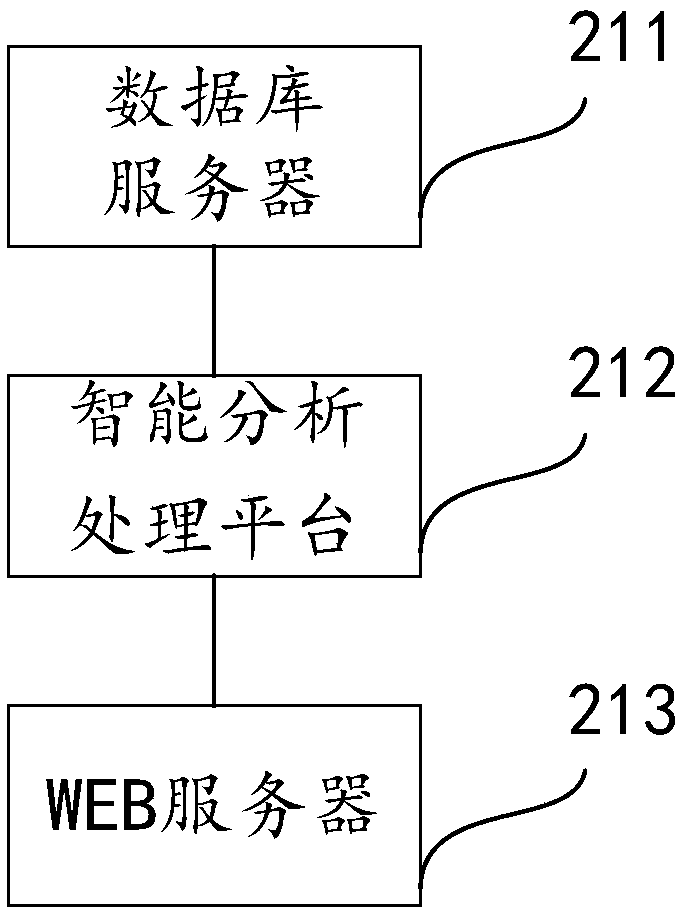

[0036] A remote fault monitoring and diagnosis system for belt conveyors based on Internet of Things technology, such as figure 1 As shown, it includes a field end 10 and a remote end 20; the field end 10 includes: a field sensor 11, a PLC system 12 and an intelligent gateway 13; the field sensor 11 is installed at a position where the belt conveyor needs to be detected; the remote The terminal 20 includes: a remote server 21 and a diagnostic terminal 22; the field sensor 11, the PLC system 12 and the intelligent gateway 13 are sequentially connected; the intelligent gateway 13 communicates with the remote server 21; the remote server 21 communicates with the diagnostic terminal 22 communication. Described PLC system 12 comprises power supply, CPU, communication interface, I / O module and programming software, is connected by cable between described field sensor 11 and PLC system 12; or RS485 connection. The transmission protocol between the intelligent gateway 13 and the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com