A kind of W CMP multi-physics process simulation method and system

A process simulation and multi-physics technology, applied in the field of WCMP multi-physics process simulation method and system, can solve problems such as extremely difficult and complex CMP mechanism, and achieve the effect of reasonable and accurate models and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

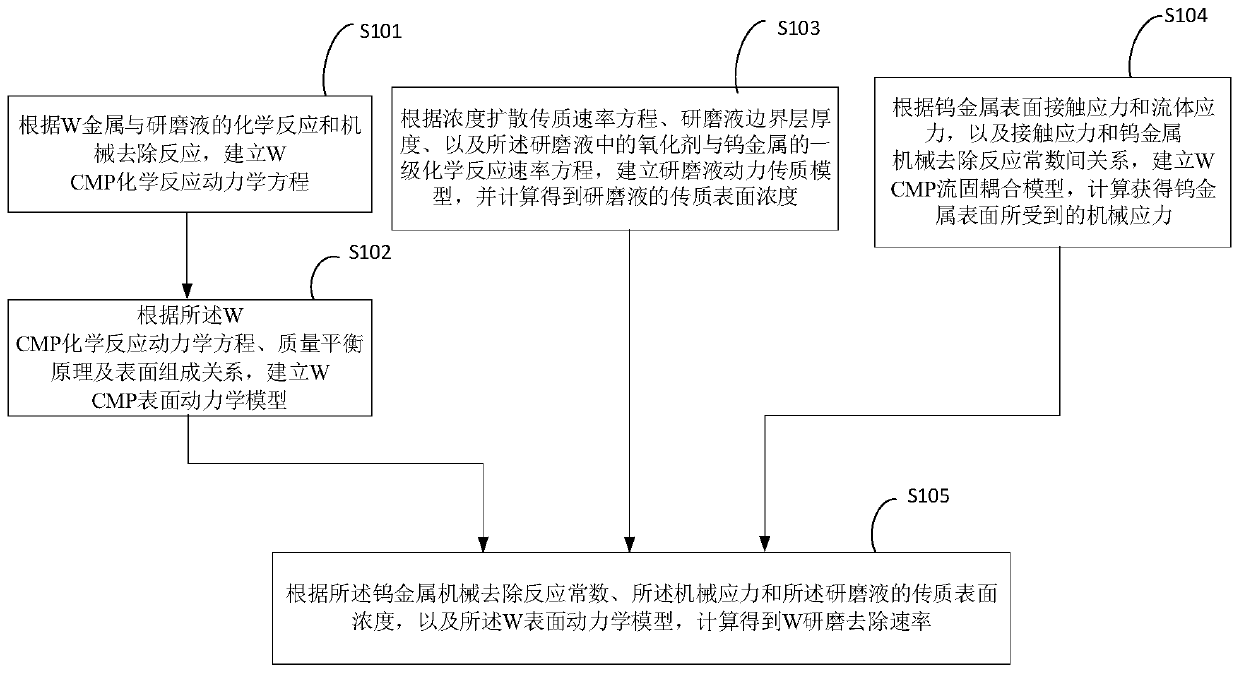

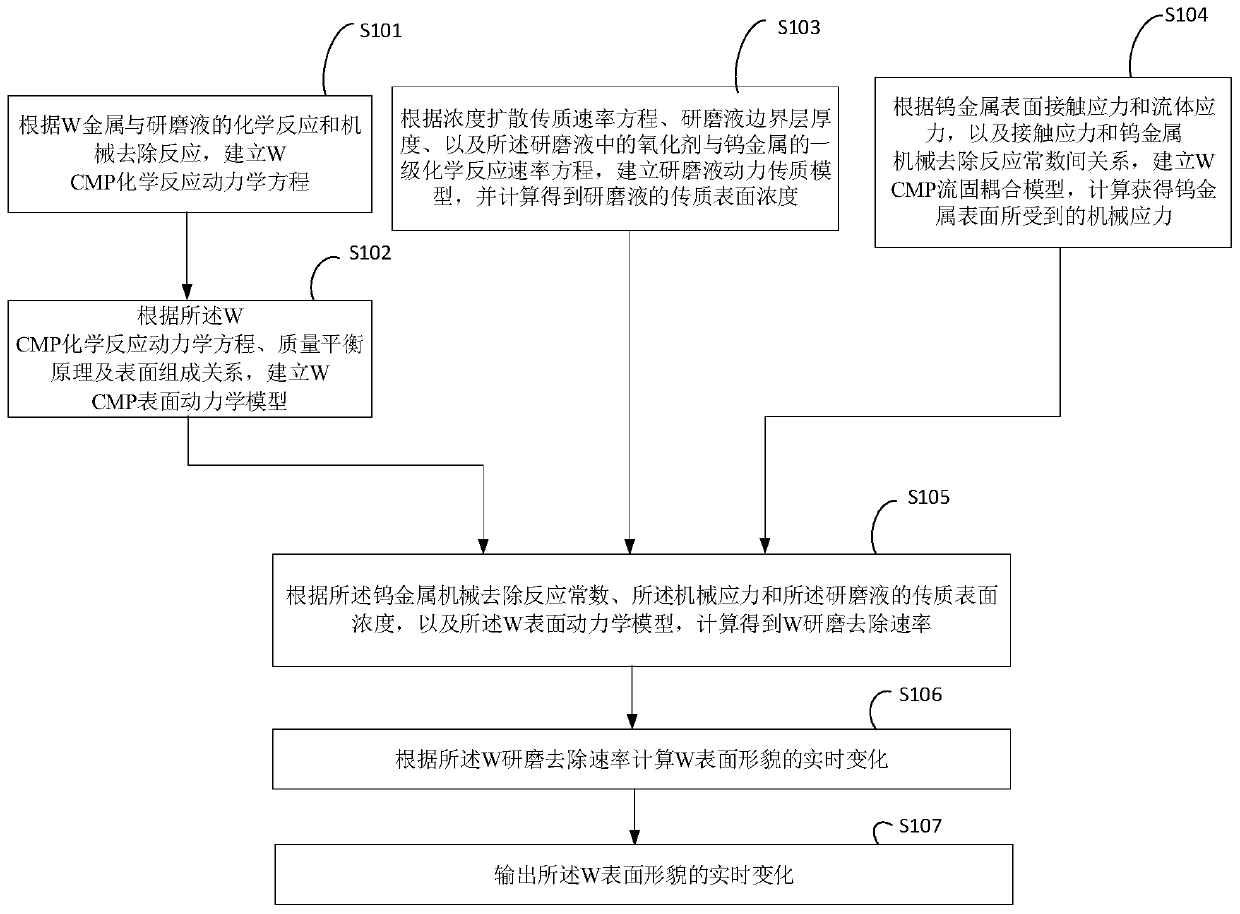

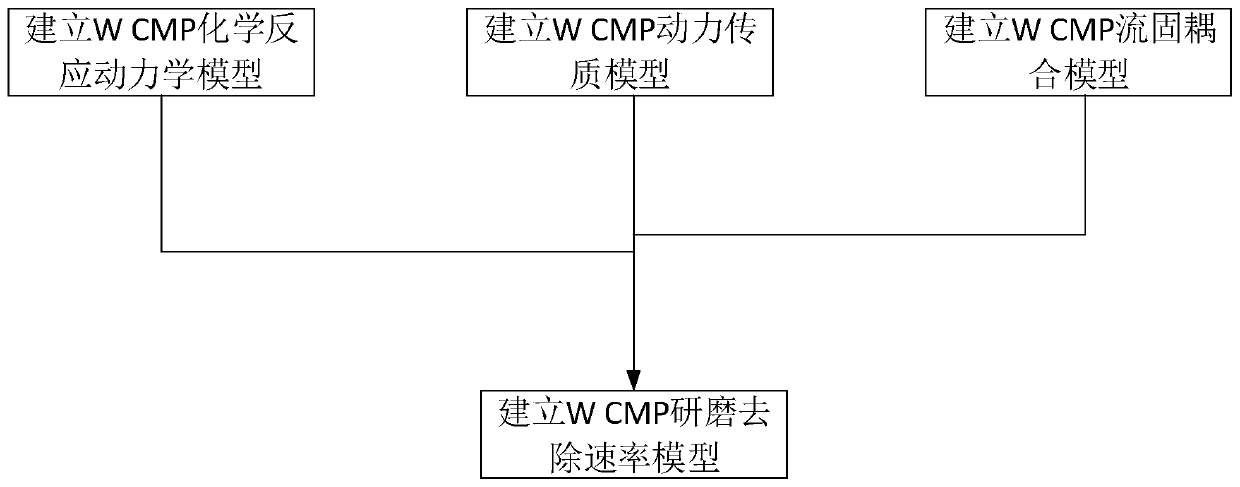

[0060] As mentioned in the background section, the flatness of tungsten gate grinding has an important impact on the performance and yield of FinFET devices. However, there is no simulation model for tungsten gate CMP in the prior art, so it cannot guide the optimization of tungsten gate CMP process.

[0061] The inventors found that the reason for the above phenomenon is that because the CMP mechanism is extremely complex and involves many physical and chemical principles, the existing CMP modeling mainly focuses on a certain aspect of grinding and removal, such as building a model from the perspective of contact removal, or from the perspective of graphic structure Establishing a model, etc., can simplify the problem and gradually reveal the CMP process in depth, but it involves less physical and chemical principles, resulting in a large difference between the CMP model and the real process, and poor accuracy.

[0062] However, the present invention mainly reveals a variety o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com