Hydraulic driveline with a secondary module

A technology of hydraulic transmission, drive train, applied to components with teeth, fluid pressure actuated system components, transmission control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

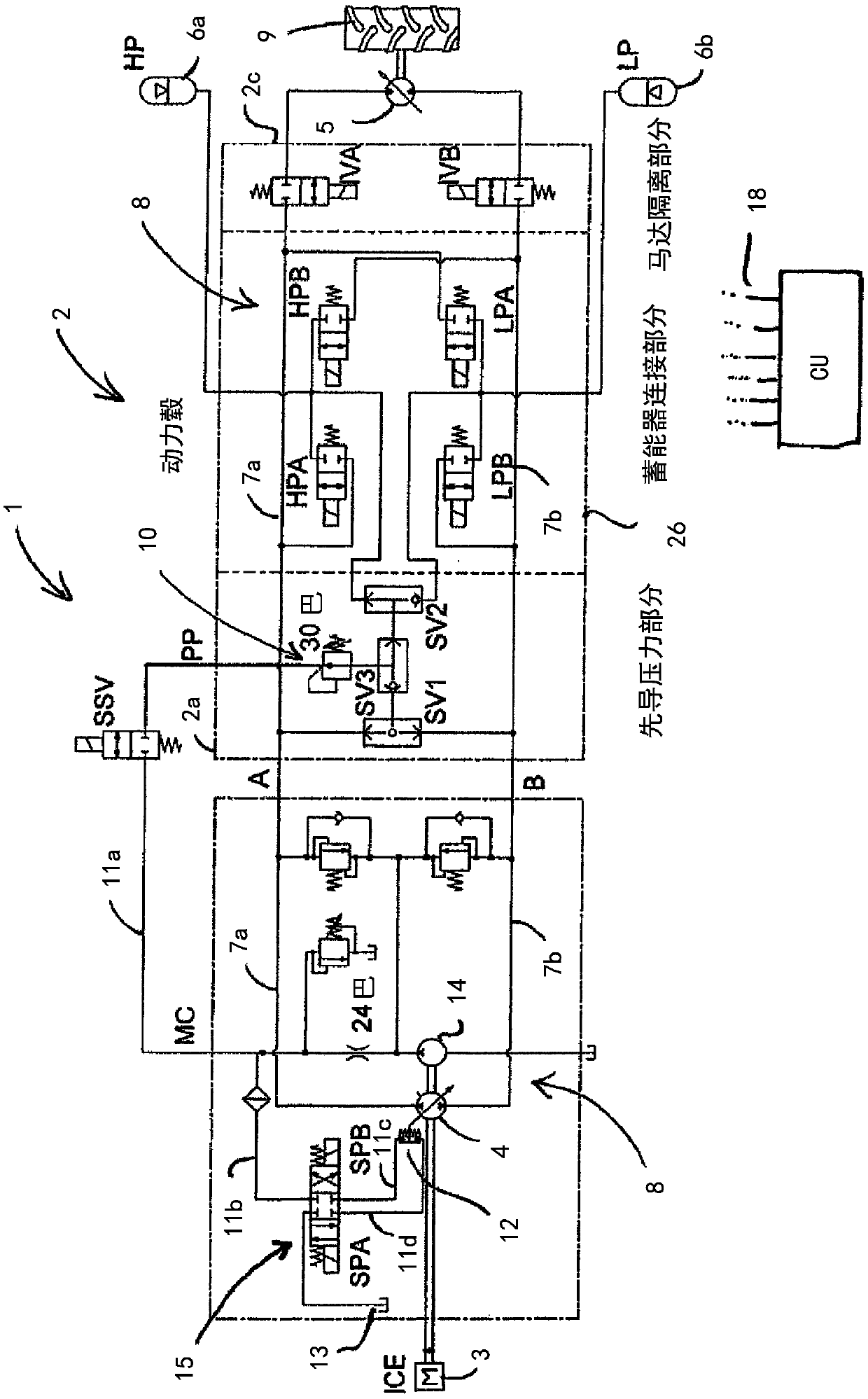

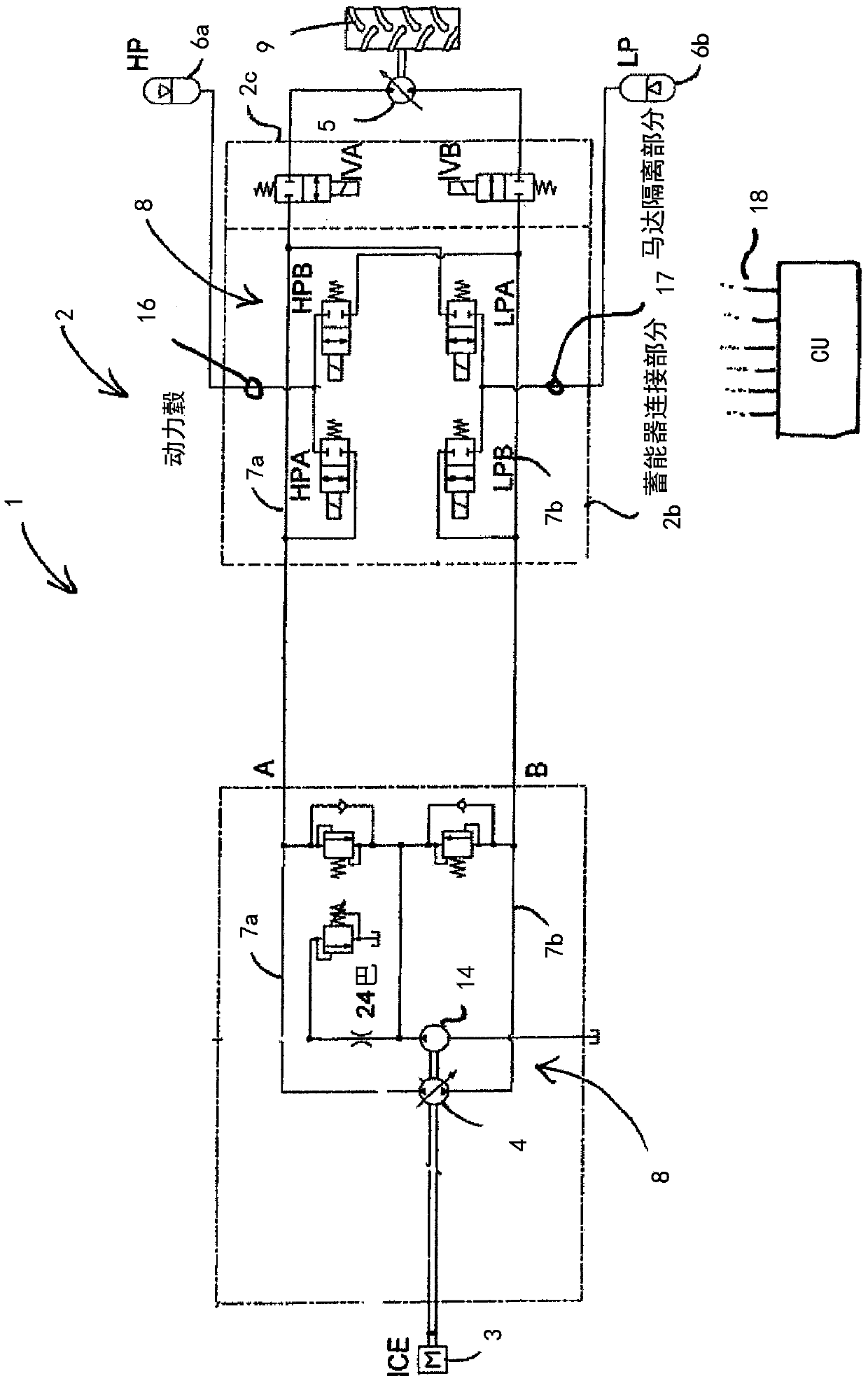

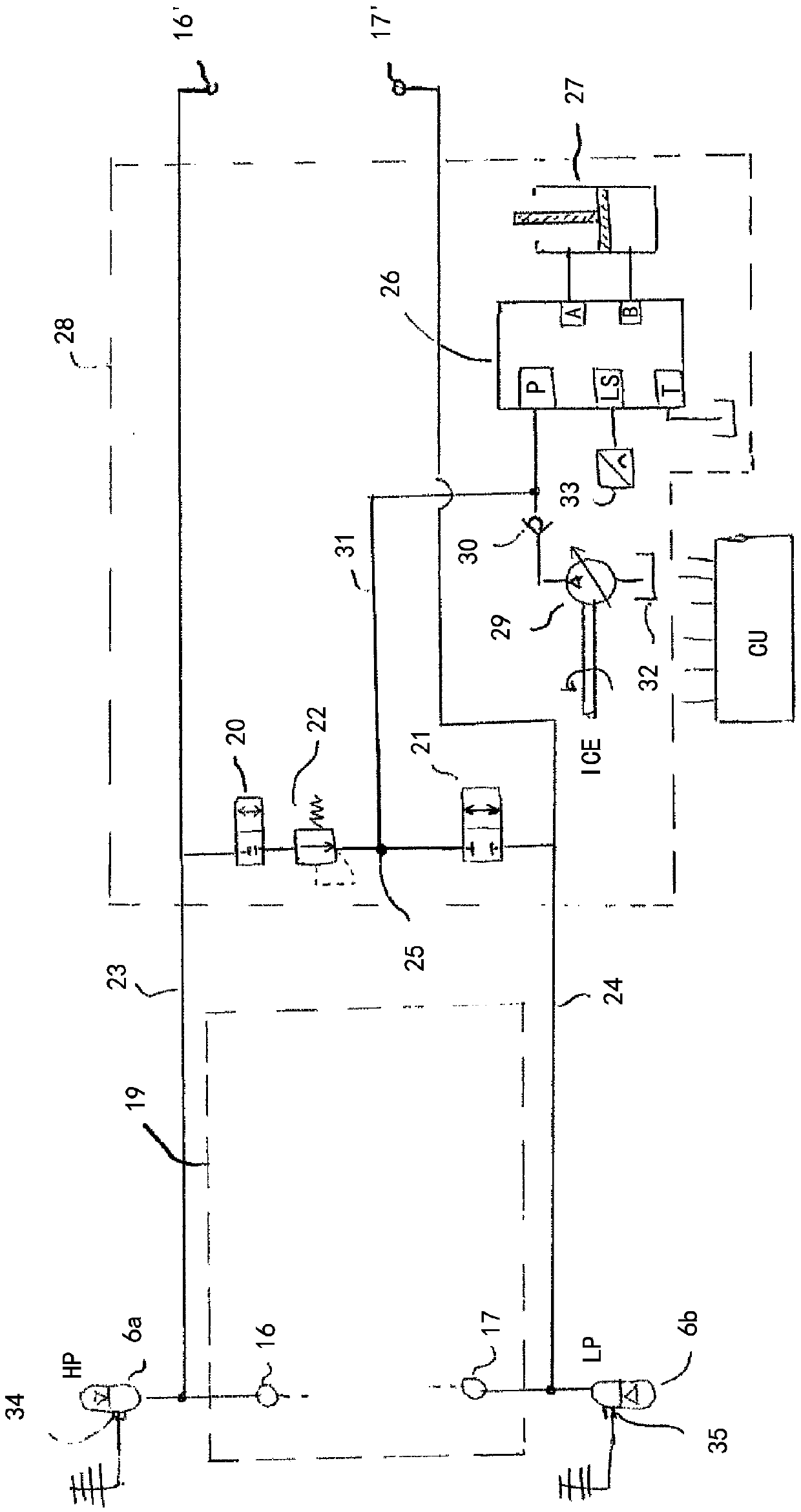

[0049] figure 1 A serial hydraulic hybrid powertrain 1 including a power hub (powerhub, or “power hub”) 2 is schematically shown. The hydraulic hybrid powertrain 1 includes an engine 3 driving a hydraulic variable displacement pump 4 . The power hub 2 is located between the pump 4 and the hydrostatic variable displacement motor 5 . The power hub 2 allows the hydraulic hybrid powertrain 1 to store hydraulic energy in a pair of hydraulic accumulators 6a, 6b when possible and to resupply the hydraulic energy when needed to save fuel or improve the performance of the hydraulic hybrid powertrain 1 performance. The high-pressure accumulator 6a and the low-pressure accumulator 6b together form a hydraulic accumulator assembly and are configured, for example, as a hydro-pneumatic bladder accumulator.

[0050] The pump 4 and the motor 5 are in fluid communication through a first main fluid line 7a and a second main fluid line 7b. The first main fluid line 7a, which typically has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com