Apparatus for gripping and conveying substrates

A transportation device and substrate technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of negative pressure fluctuations, high noise, high energy, etc., and achieve the effect of establishing and eliminating negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

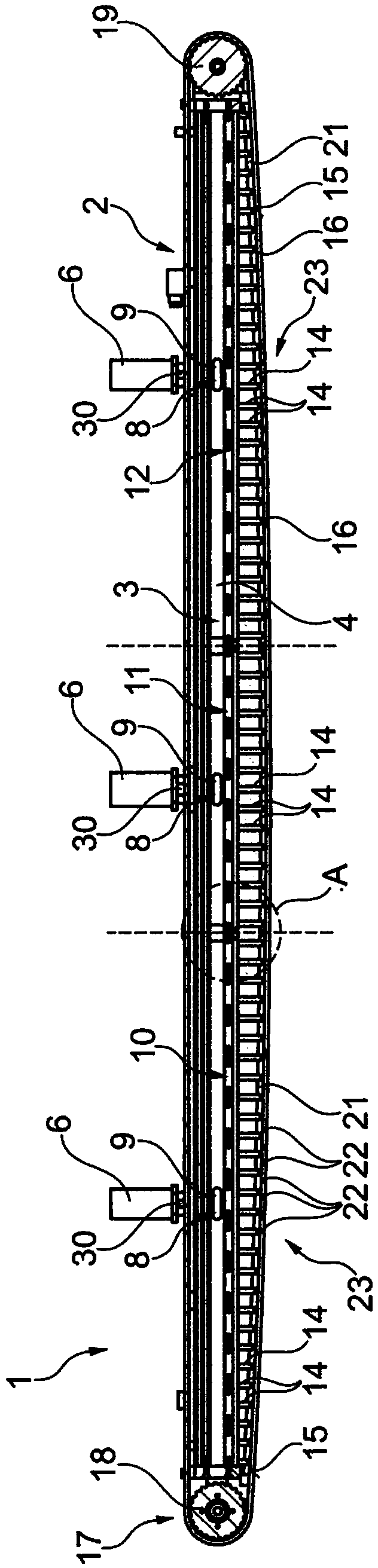

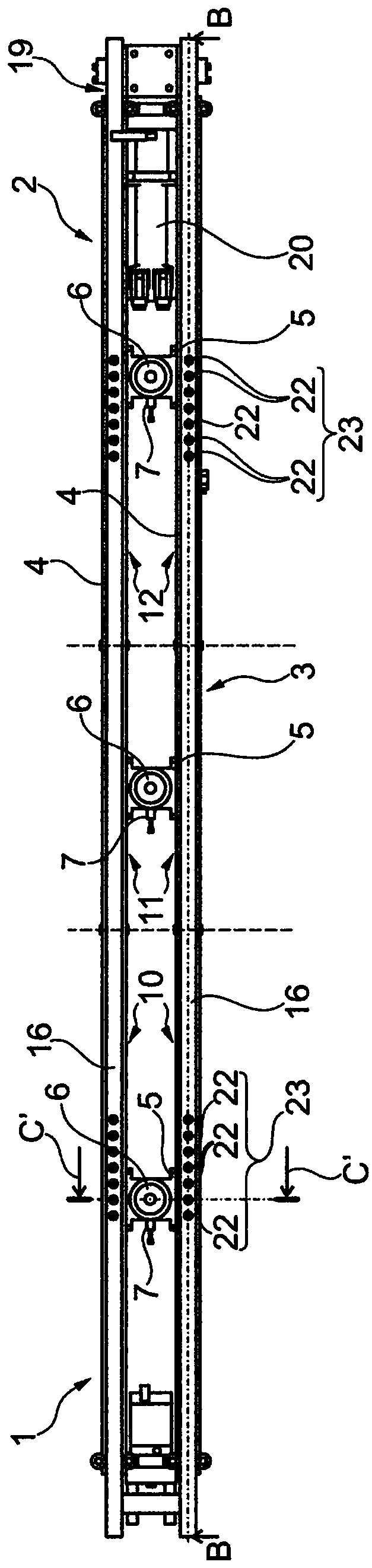

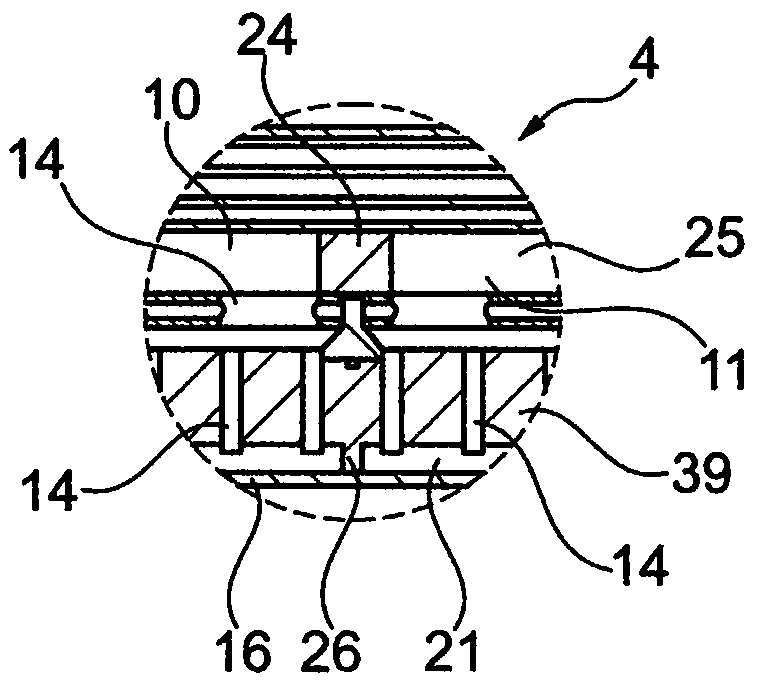

[0023] figure 1 An advantageous device 1 for gripping and transporting substrates not shown in detail here is shown in a simplified longitudinal section, which is shown in figure 2 Shown in top view. exist figure 2 Its longitudinal section is shown by dashed line B-B in . The device 1 has a gripping head 2 which is elongated and whose length is significantly greater than its width and height. The gripping head 2 is designed in multiple parts. Here, the gripping head 2 has a support structure 3 which is formed from two hollow formations 4 arranged parallel to each other and spaced apart from one another and a plurality of intermediate elements 5 by connecting the two hollow formations 4 to one another.

[0024]According to this embodiment, the three intermediate elements 5 each carry a Venturi nozzle 6 with at least one pressure connection 7 and suction connection 8 . The pressure connection 7 can be connected to a compressed air generator not shown in detail here or to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com