Apparatus and method for purifying modified asphalt waste gas through catalytic oxidation method

A technology of modified asphalt and catalytic oxidation, which is applied in the direction of chemical instruments and methods, combined devices, separation methods, etc. It can solve the problems of incompatibility between environmental quality standards and regulations, incomplete purification effect, and reduction of non-methane total hydrocarbons. Achieve the effects of reducing the amount of secondary pollutants, improving safety, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

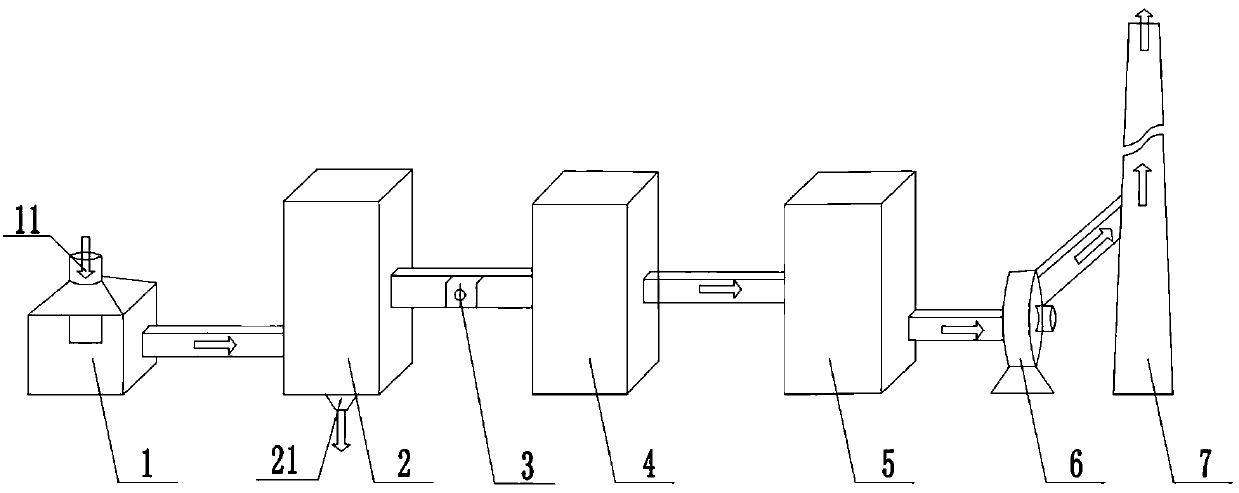

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown: the present invention includes an atomization device 1, a modified asphalt waste gas inlet 11, an adsorption device 2, a solid-containing waste liquid discharge port 21, an oxidant mixing device 3, an oxidation device 4, a catalytic device 5, a fan 6, and a chimney 7; The non-toxic asphalt waste gas enters the atomization device 1 from the modified asphalt waste gas inlet 11. Under the action of the atomization device 1, the high-boiling point organic matter in the modified asphalt waste gas is instantly transformed from gaseous to aerosol; then it is transported to the adsorption device 2, modified Particles and aerosols in the asphalt waste gas are absorbed into semi-solid and collected by the solid-containing waste liquid discharge port 21; the modified asphalt waste gas with no particles and no dust is transported to the oxidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com