Follow-up counter torque device

A counter-torque and follow-up technology, applied in the field of follow-up counter-torque devices, can solve the problems of increasing labor intensity of workers, low qualification rate of product assembly quality, and limited installation space, so as to reduce labor intensity of workers and ensure product assembly. Quality, solve the effect of small operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

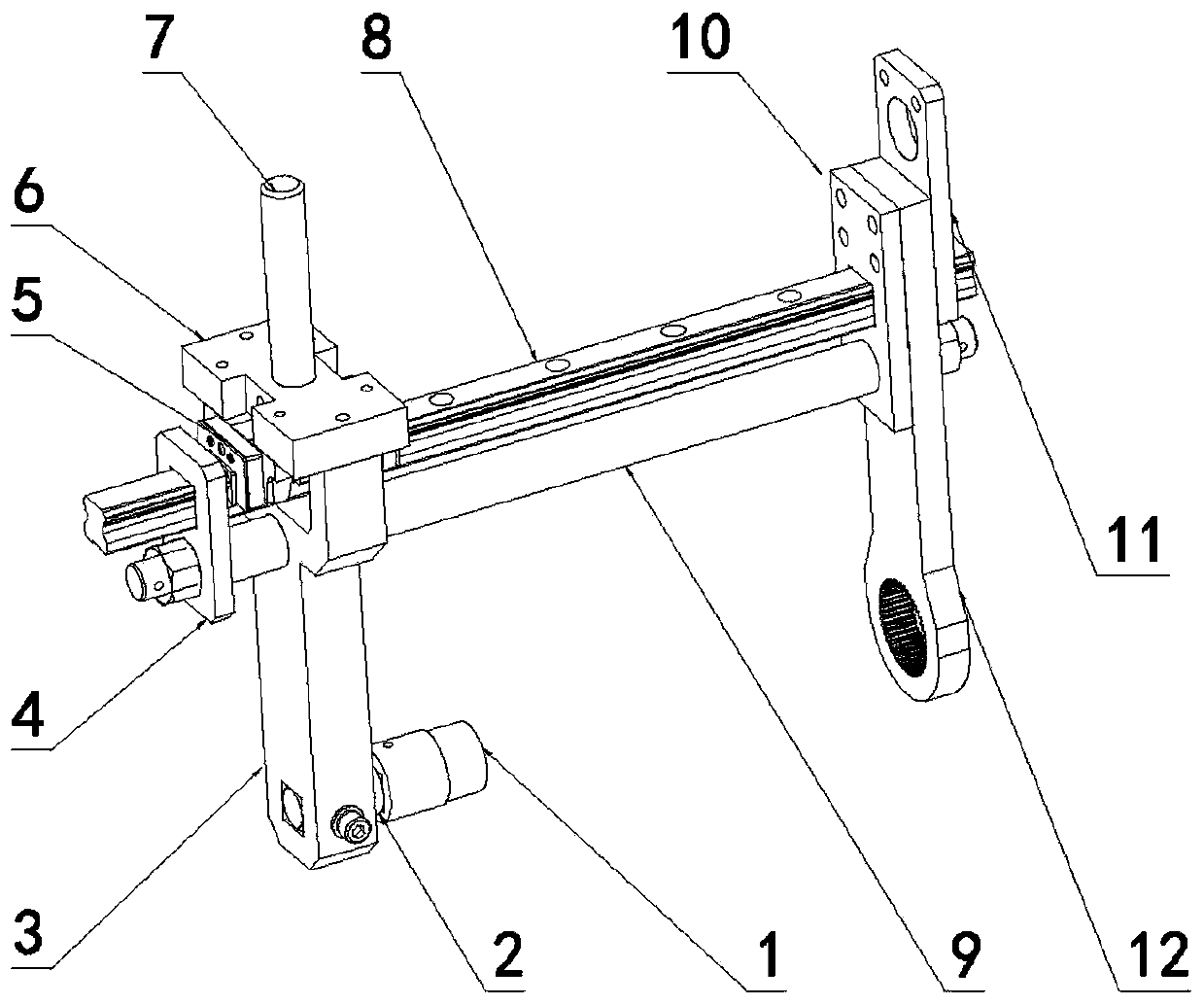

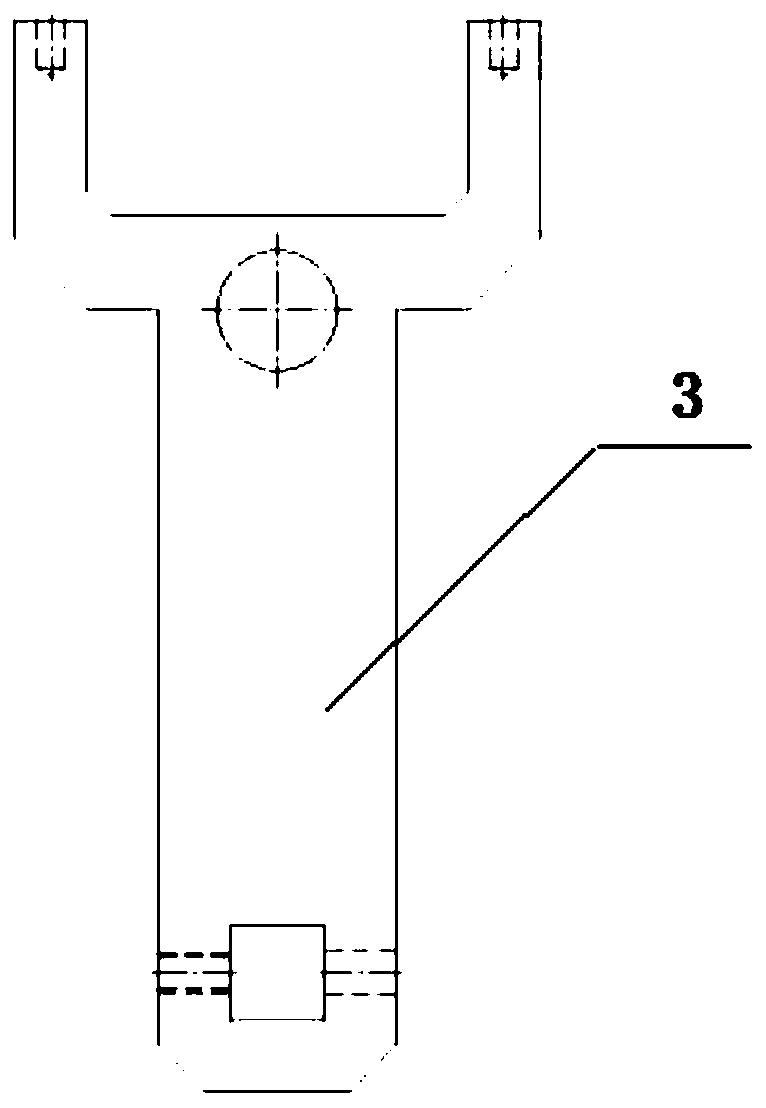

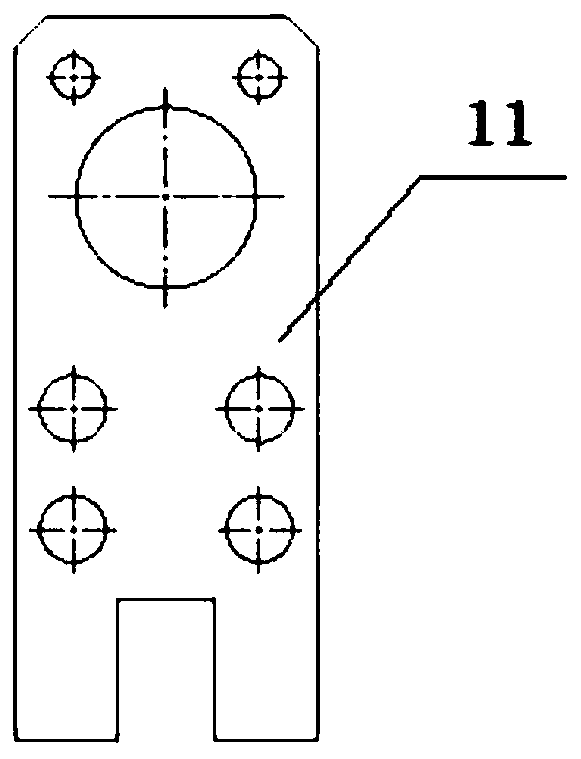

[0018] Connect the balancer through the round hole of the positioning clamp 11, and hang a follow-up anti-torque device on the assembly station of the automobile production line. When the car body to be assembled is transported to this station, the worker puts the nut in the sleeve 1 with his left hand. Hold the electric wrench in your right hand to bring the bolt into the nut, then hold the handle 7 of the follow-up anti-torque device with your left hand, and operate the electric wrench to rotate with your right hand. A follow-up sliding body 3 of a follow-up anti-torque device is guided by the ball slide rail and the guide post, and it also moves forward. After reaching a fixed torque, the electric wrench stops working, the right hand withdraws the electric wrench, and the left hand reverses. Once pulled, a follow-up sliding body 3 of a follow-up anti-torque device resets, and this operation completes the work.

[0019] The square ball linear guide is a commercially availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com