Syderolite mixing device for ceramic production

A technology of mixing device and clay, which is applied in the directions of mixing operation control device, clay preparation device, clay mixing device, etc., can solve problems such as poor plasticity, and achieve the effects of convenient use, improved efficiency and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

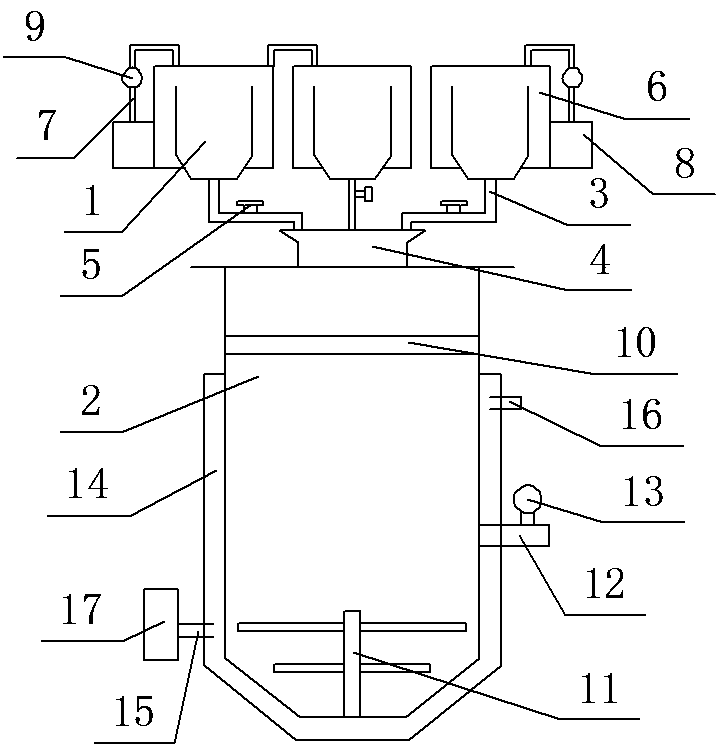

[0010] Embodiment 1: as figure 1 As shown, the present invention comprises several raw material storage tanks 1 and the stirring tank 2 placed below the raw material storage tank 1, each raw material storage tank 1 is respectively provided with a separate discharge pipe 3 and is connected with the stirring tank 2 The feed port 4 is connected, the discharge pipe 3 is provided with a metering control valve 5, and each of the raw material storage tanks 1 is respectively covered with a closed dust cover 6, and the dust cover 6 is opened. There is a material suction port, a material return pipe 7 is connected outside the material suction port, and the other end of the material return pipe 7 is connected with a material return box 8, and a negative pressure device 9 is provided on the material return pipe 7, and the inner upper part of the mixing tank 2 A reversible weighing pan 10 is provided at the inner bottom of the stirring tank 2, and a stirring device 11 is provided at the bo...

Embodiment 2

[0011] Embodiment 2: Same as the above embodiment 1, wherein the above-mentioned raw material storage tank 1 is provided with a stirring rod.

[0012] The use process of the present invention: each raw material storage tank 1 is filled with different raw materials, the metering of each raw material is controlled by opening the metering control valve 5, and all raw materials enter the weighing pan 10 of the mixing tank 2 through the discharge pipe 3 , when the weight in the weighing pan 10 reaches the maximum weight that can be stirred, the controller connected to the weighing device of the weighing pan 10 will control the motor to start, turn the weighing pan 10, and pour all the raw materials into the mixing tank 2 At the bottom, open the flow control valve 13, put in the amount of water proportional to it, and the stirring device 11 starts to stir until the noodles are formed. When the temperature is low, the hot air blower 17 can be turned on to heat the heating layer 14, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com