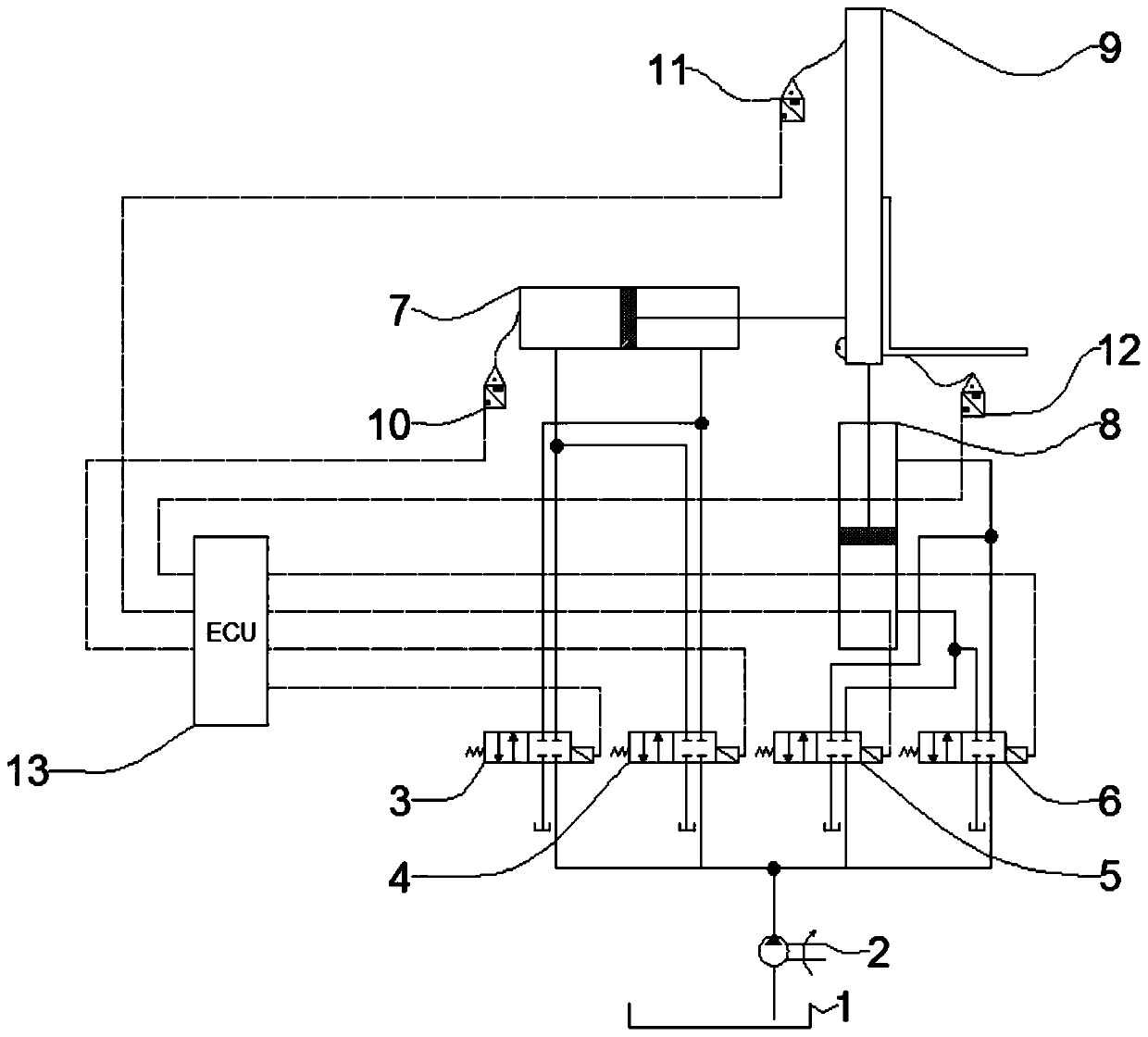

Safety control system for fork of forklift and method of control system

A safety control and fork technology, which is applied in the direction of lifting device, fluid pressure actuating device, servo motor assembly, etc., can solve the problem of forklift tipping, fork backward tilting speed not being controlled accordingly, easy crushing or smashing operator issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] Example 1: Cushioning control of the limit position of the fork

[0134] Fork forward tilt operation:

[0135] First, according to the forward position angle of the fork buffer control and the corresponding buffer speed determination method, it is determined that the forward position angle of the fork buffer control in this state is 4°, and the fork buffer speed is 1.5° / s;

[0136] Secondly, the rated test weight of the fork shovel is 3.5 tons, and the forward tilting work is performed at a full speed of 3° / s from the horizontal position. reduce the oil filling speed of tilt cylinder 7, so that the fork moves to the limit position of forward tilt at the corresponding buffer speed of 1.5° / s, so as to complete the buffer control of the limit position of forward tilt of the fork; during the operation of the fork, the rated The experimental weight did not move forward, and the ground pressure of the rear tire measured by the pressure sensor changed steadily.

[0137] Fork...

Embodiment 2

[0140] Example 2: Fork forward tilt angle limitation

[0141] First, according to the method of determining the installation height of the height switch, the installation height of the height switch is determined to be 1.68m;

[0142] Secondly, according to the determination method of the forward tilt limit angle of the fork, the forward tilt limit angle of the fork under the load of 3.5T is determined to be 1°;

[0143] When the rated test weight of the fork is 3.5 tons for lifting work, the lifting height of the fork is 3m, and the test weight exceeds the limit weight of the fork by 0.25 tons, when the fork is tilted forward from the horizontal position to the forward tilt angle of 1 °, the forward tilt solenoid valve 3 is closed, and the oil pump 2 stops supplying oil to the tilt cylinder 7 to complete the control of the forward tilt angle of the fork; during the operation of the fork, the rated test weight does not move forward, and the pressure sensor detects that the rea...

Embodiment 3

[0144] Example 3: Speed limit control for fork backward tilt

[0145] First, the rated test weight of the pallet fork is 3.5 tons for lifting work, the lifting height of the pallet fork is 3m, and the experimental weight exceeds the limit weight of the pallet fork by 0.25 tons, and the pallet fork is tilted backward from the horizontal position;

[0146] Secondly, according to the determination method of the reclining speed of the fork, the reclining speed of the fork under the load of 3.5T is determined to be 2° / s;

[0147] When the fork is tilted backward from the horizontal position, the opening of the backward tilt solenoid valve 4 decreases, the oil supply speed of the oil pump 2 to the tilt cylinder 7 decreases, and the fork tilts backward at a corresponding backward tilt speed of 2° / s to complete the cargo. Fork rear tilt speed control; during the operation of the fork, the rated test weight does not move backward, and the ground pressure of the front tire measured by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com