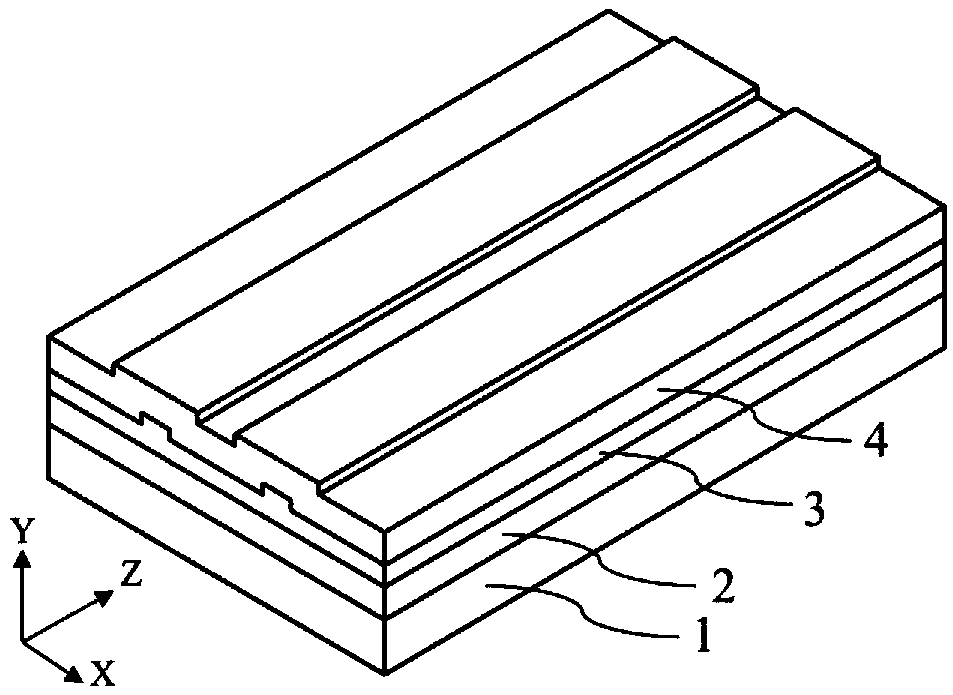

Planar optical waveguide, preparation method thereof and thermo-optical device

A technology of planar optical waveguide and thermo-optic coefficient, which is applied in the field of optical waveguide, can solve the problems of no mature mechanism, slow response of optical waveguide, and insufficient sensitivity of optical waveguide thermo-optic device response, etc., to reduce thermo-optic response time, improve response speed and The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the planar optical waveguide described in the above technical solution, including:

[0056] a) growing an inorganic material lower cladding layer on the substrate surface by using a liquid phase source deposition method;

[0057] b) etching the polymer core layer on the cladding surface under the inorganic material;

[0058] c) growing an inorganic material cladding layer on the surface of the polymer core layer by using a liquid phase source deposition method;

[0059] In the step a), the deposition temperature of the liquid phase source deposition method is 80-120°C;

[0060] In the step c), the deposition temperature of the liquid phase source deposition method is 80-120°C.

[0061] According to the present invention, the lower cladding layer of inorganic material is grown on the surface of the substrate by using the liquid phase source deposition method.

[0062] In the present invention, cleaning is pref...

Embodiment 1

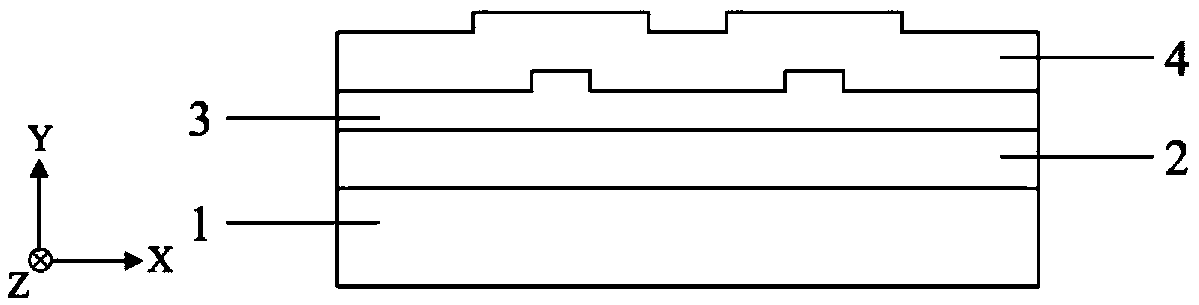

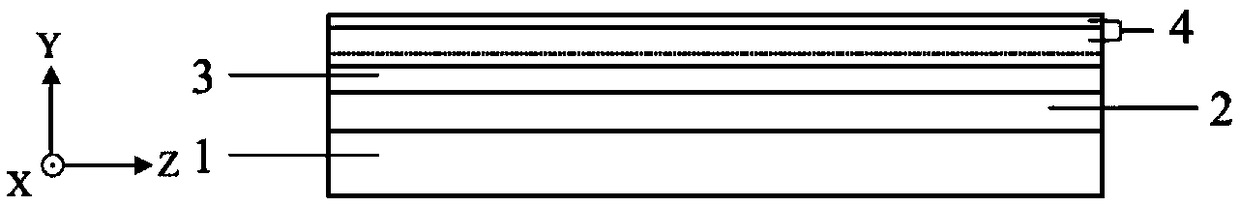

[0073] SiO 2 Lower cladding layer-SU-8 core layer-SiO 2 Fabrication of Overclad Ridge Optical Waveguide

[0074] see Figure 5 , Figure 5 It is a flow chart of the preparation of the ridge optical waveguide in Example 1, and the specific process is as follows:

[0075] S11: cleaning the silicon-based substrate 5 . Wash with acetone, methanol, and isopropanol in a 55°C water bath for 5 minutes, rinse the substrate (thickness: 200 μm) with deionized water and dry it under nitrogen; again use acetone, methanol, and isopropanol in a 55°C water bath Rinse the substrate with deionized water for 10 min, blow dry it under nitrogen, and heat it on a hot plate at 100°C for 10 min to dry the water vapor.

[0076] S12: Growing SiO 2 Lower cladding 6. Deposition of zero-stress SiO on substrate 5 by liquid source deposition equipment LS-CVD 2 The film is 3 μm, and the deposition temperature is 80-120°C.

[0077] Fabrication of the ridge waveguide core:

[0078] S13: Prepare the f...

Embodiment 2

[0091] The thermal-optical response characteristics of the optical waveguides of Example 1 and Comparative Examples 1-2 were detected respectively (tested by Gwinstek AFG-3081 function generator and Tektronix MSO4104B signal generator), and the test results were as follows: Figure 11 as shown, Figure 11 It is the thermo-optic response characteristic detection result figure of embodiment 2; Wherein, curve 1 is the thermo-optic response curve of the optical waveguide obtained in embodiment 1, curve 2 is the thermo-optic response curve of the optical waveguide obtained in comparative example 1, and curve 3 is the comparative example 2 Thermo-optic response curve of the obtained optical waveguide. It can be seen that the rise time t of Comparative Example 1 r_PMMA-PMMA 327μs, fall time t f_PMMA-PMMA is 327μs. Rise time t of comparative example 2 f_PMMA-Silica 196µs, fall time t f_PMMA-Silica is 163μs. The rise time t of Example 1 r_Silica-Silica 168µs, fall time t f_Sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com