Telescopic concrete pump pipe assembly

A technology of concrete pump pipe and telescopic pipe, which is applied in the direction of construction, building structure, and building material processing, etc., to achieve the effects of ensuring stability, high control precision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

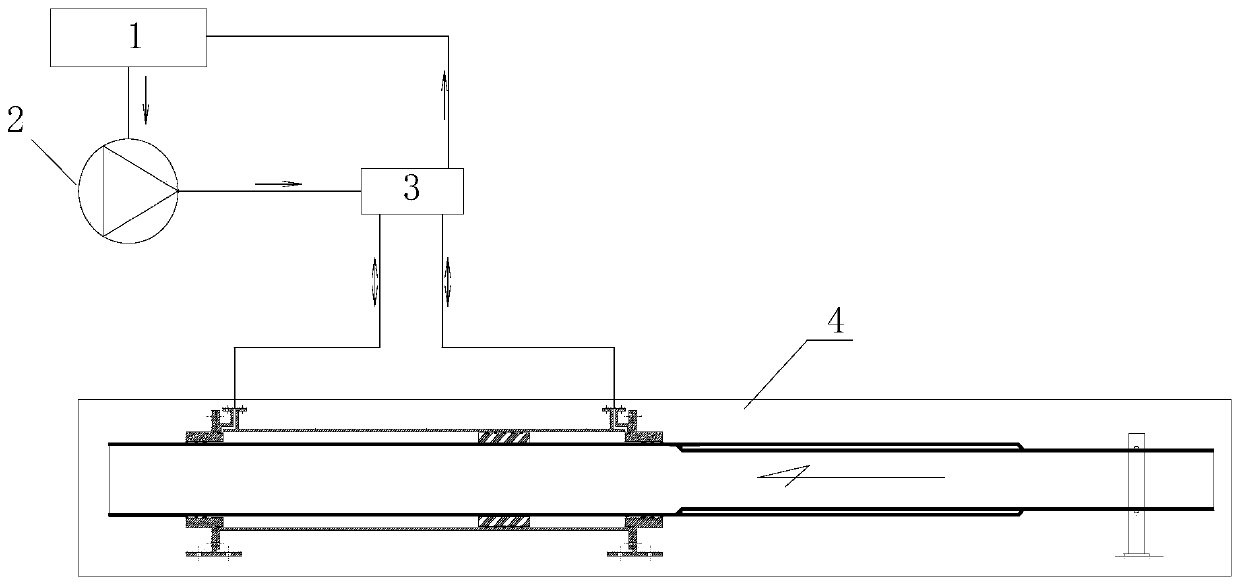

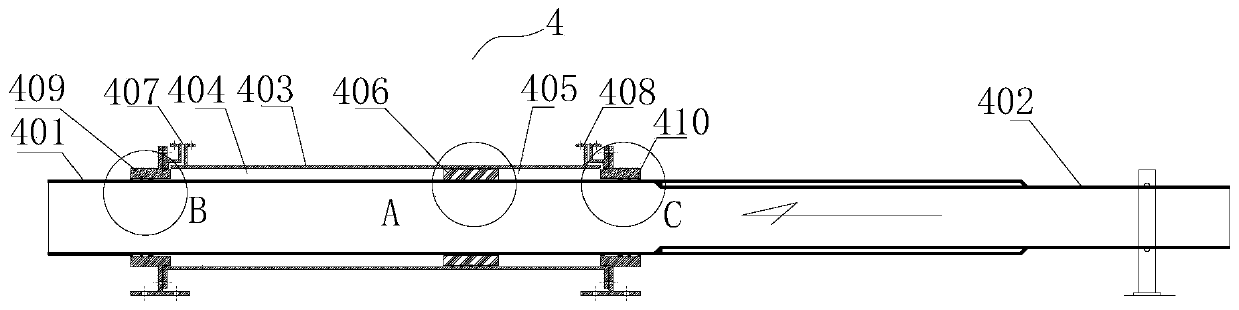

[0022] Such as figure 1 and figure 2 The telescopic concrete pump pipe integration of the present invention shown includes the original pipe 402, the telescopic pipe 401, the cylinder 403, the pump 2 and the pressure supply equipment (ie, the oil tank 1 in the figure).

[0023] The original pipe 402 is fixed on an external equipment support, or fixed relative to an external building, and the telescopic pipe 401 is movably fitted and socketed outside the original pipe 402 and can slide axially relative to the original pipe 402 . The outer wall of the end of the original pipe 402 is covered with a sealing ring 424 at the end of the original pipe to seal the gap between the original pipe 402 and the telescopic pipe 401 .

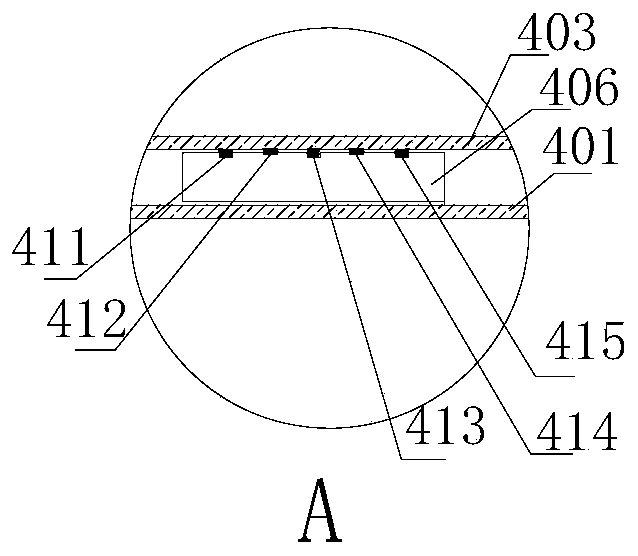

[0024] The outer wall of one section of the telescopic tube 401 is sleeved with a cylinder 403, and an annular chamber is formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com