Steel strip slip simulation method and device for continuously variable transmissions

A technology of continuously variable transmission and steel belt, applied in transmission control, design optimization/simulation, instruments, etc., can solve problems such as slip rate jitter, maximum torque fluctuation, clutter, etc., to reduce misjudgment, improve quality and Efficiency, the effect of reducing slip rate jumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

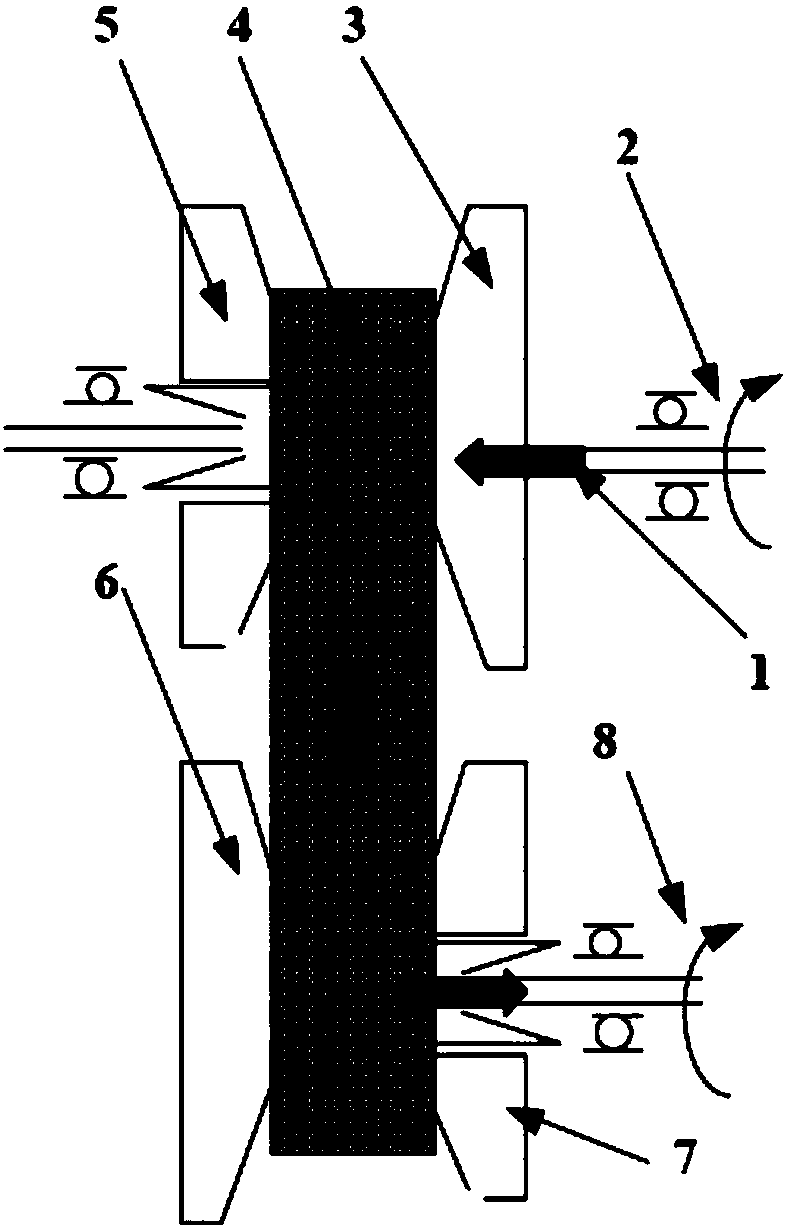

Image

Examples

Embodiment Construction

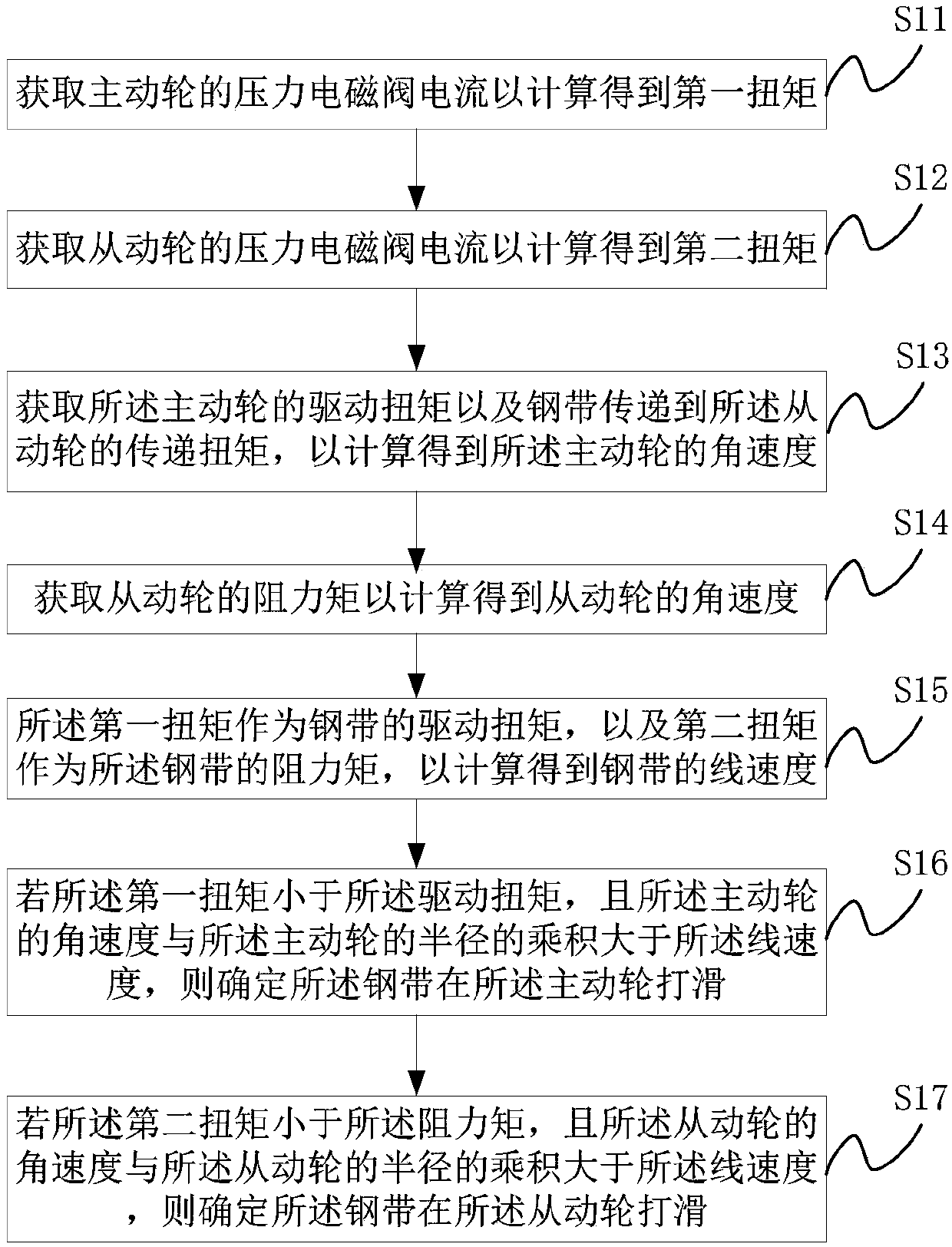

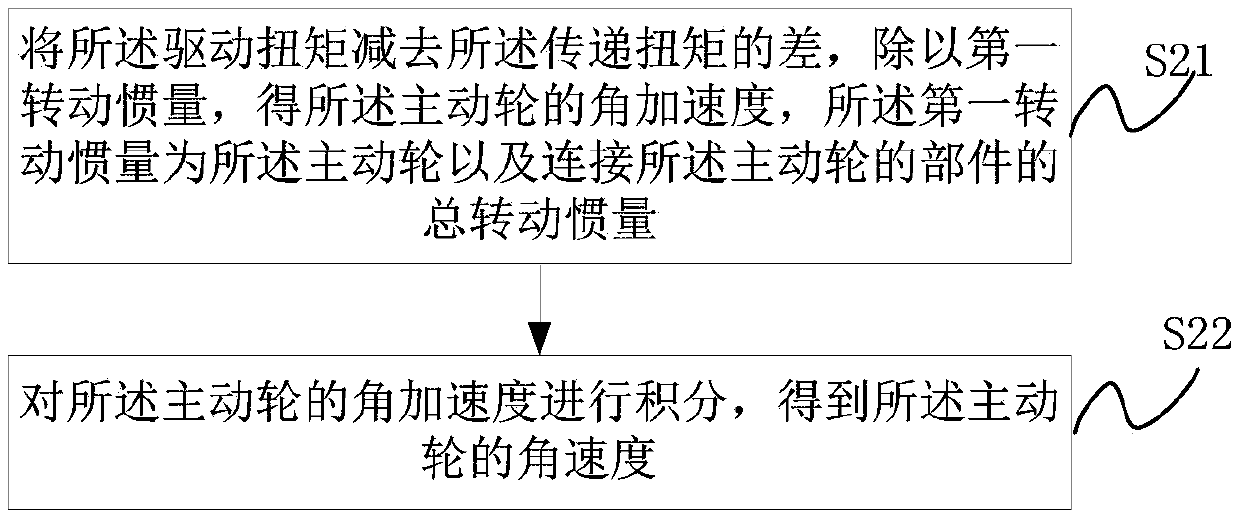

[0055] Due to the error in the current acquisition channel itself, and the addition of flutter function to the output current of the electronic control unit, the pressure solenoid valve current collected by the physical model in the hardware-in-the-loop test environment has interference and fluctuations. Then cause the calculated maximum torque to also fluctuate, if the maximum torque that the driving wheel or the driven wheel can actually transmit is less than the torque that it actually transmits, it will be directly judged that there is slipping, which will cause a discrepancy with the actual situation; The relationship between the strip linear velocity, angular velocity and radius is limited, that is, when the maximum torque is less than the actual transmitted torque, it is also judged whether the strip linear velocity, angular velocity and radius satisfy the formula, and then determine whether the steel strip slips, reducing the slip state Misjudgment, thereby reducing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com