Pipeline communication type power supply system and safety management method thereof

A power system and pipeline technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as hidden dangers of battery pack safety, insufficient battery pack design and management methods, etc., to protect personal safety and property, and respond quickly in real time. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

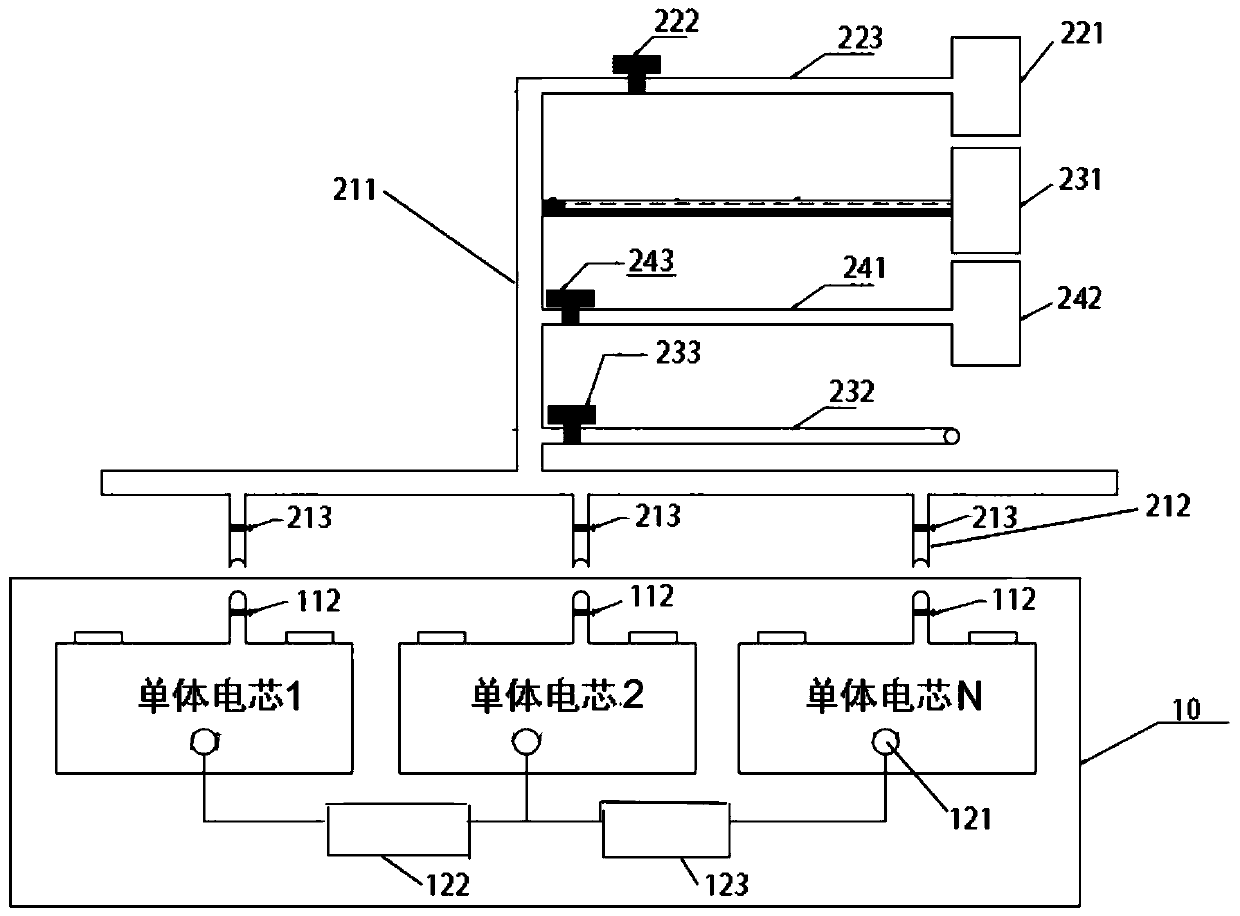

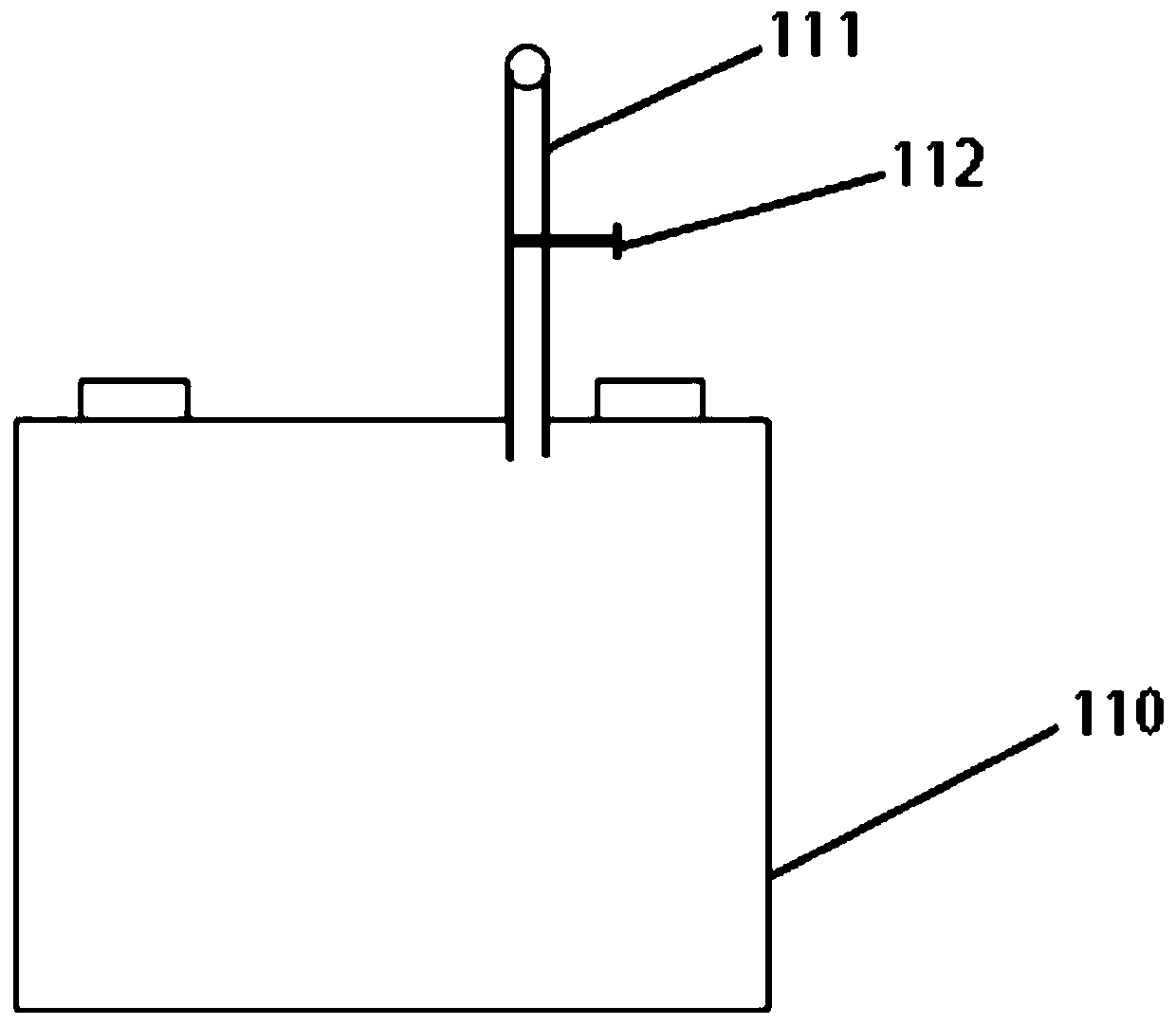

[0045] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a pipeline-connected power supply system, figure 2 It is a structural schematic diagram of a single cell, and the power system includes:

[0046] A pipeline connection type power supply system, comprising a battery pack 10 and a pipeline connection control device;

[0047]The pipeline connection control device includes an external pipeline 211, and a flame retardant liquid tank 221 connected to the external pipeline 211; a flame retardant solenoid valve 222 is provided in the external pipeline 211; wherein, the flame retardant liquid tank 221 can be used to store liquid nitrogen, water , aqueous solution, or other flame retardant liquid or coolant;

[0048] The battery pack 10 includes several single cells 110; the end of the external pipe 211 away from the flame retardant liquid tank 221 is provided with several branch pipes 212 for connecting the single cells 110; The flame retardant l...

Embodiment 2

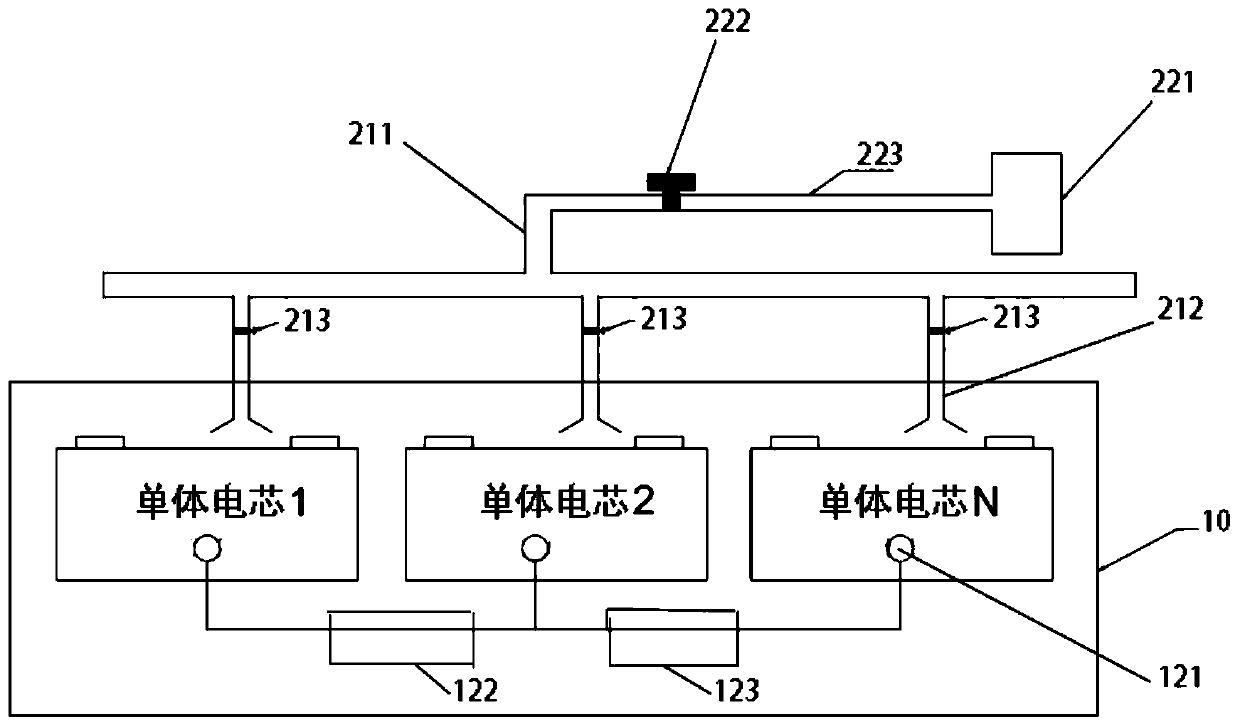

[0067] This embodiment is optimized on the basis of Embodiment 1, so that this power supply system can be applied to the closed battery pack 10, please refer to image 3 , which is a schematic structural diagram of another pipeline-connected power supply system, which specifically includes:

[0068] The battery pack 10, the external pipeline 211, and the flame retardant liquid tank 221 connected to the external pipeline 211; a flame retardant solenoid valve 222 is provided between the external pipeline 211 and the flame retardant liquid tank 221; wherein, the flame retardant liquid tank 221 can be used Store liquid nitrogen, water, aqueous solution, or other flame-retardant liquids or coolants;

[0069] The battery pack 10 includes several single cells 110; the end of the external pipe 211 away from the flame retardant liquid tank 221 is provided with several branch pipes 212 corresponding to the single cells 110;

[0070] Each branch pipe 212 is equipped with a branch soleno...

Embodiment 3

[0075] Correspondingly, the present invention also provides a safety management method for a pipeline-connected power supply system, which is applicable to the power supply system mentioned in Embodiment 1 or Embodiment 2. Please refer to Figure 4 , which is a flow chart of a safety management method for a pipeline-connected power supply system, the method specifically includes the following steps:

[0076]S1: Obtain the real-time status of each single cell in the battery pack, the real-time status includes the temperature and voltage of the single cell;

[0077] Specifically, the battery pack also includes a battery state monitoring module; the battery state monitoring module includes several state acquisition modules arranged on the single cells, and the state collection modules of the battery state monitoring module obtain the data of each single cell in the battery pack. real-time status;

[0078] S2: Determine whether the temperature and voltage of each single cell exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com