Crisp fried Chinese prickly ash, production technology thereof, crisp fried Chinese prickly ash seasoning, and production technology of crisp fried Chinese prickly ash seasoning

A production process and seasoning technology, which is applied in the field of solid seasoning, can solve the problems of ignoring the deep processing of peppercorns, and achieve the effect of improving controllability and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

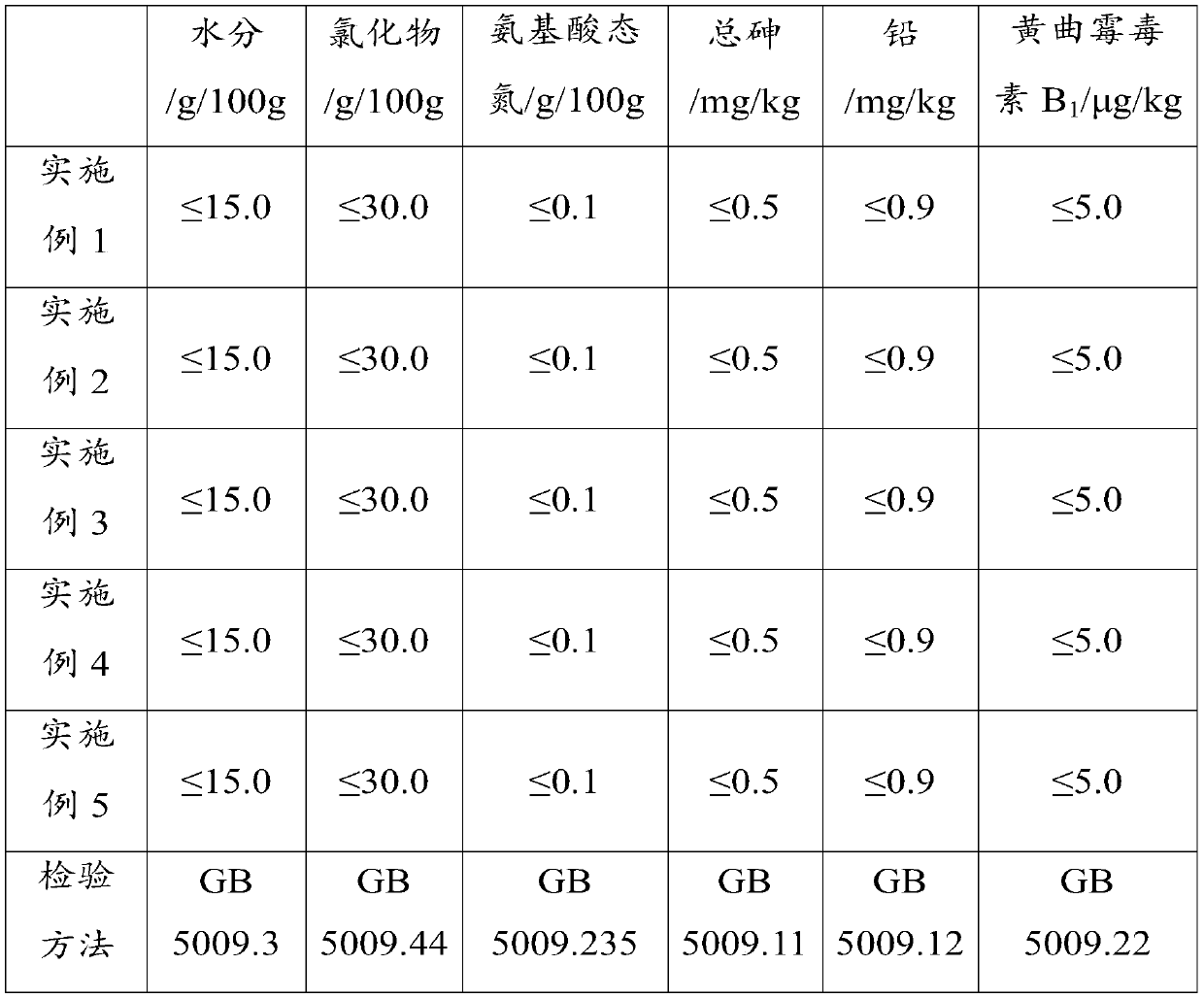

Examples

Embodiment 1

[0053] The present embodiment provides a kind of crispy prickly ash production process, comprising:

[0054] The selected peppercorns are sorted through a three-layer vibrating sorter and a specific gravity stoner in turn, and the sorted peppercorns are cleaned by a washing machine to obtain clean peppercorns. Then through the double water removal of the vibration water remover and the multi-stage air flow water remover, clean and dry peppercorns are obtained.

[0055] Under the conditions of 60°C and 0.07MPa, the Chinese prickly ash was softened in a softener for 10 minutes. Soften the pepper skin and shell, and remove bitter, astringent and other odors as well as some volatile oils.

[0056] The softened prickly ash enters a closed electromagnetic frying pan, and is sprayed with edible oil for frying. Wherein, the mass ratio of the softened Chinese prickly ash to the edible oil is 100:8. Strictly control the temperature of the frying process, wherein the frying temperatur...

Embodiment 2

[0058] The present embodiment provides a kind of crispy Chinese prickly ash production process, and the difference with embodiment 1 is:

[0059] The mass ratio of softened Chinese prickly ash to edible oil is 100:8. Strictly control the temperature of the frying process, wherein the frying temperature is preferably 110°C, and the frying time is determined until oil bubbles form on the surface of the peppercorns, no water vapor overflows, and the color begins to darken.

Embodiment 3

[0061] The present embodiment provides a kind of crispy Chinese prickly ash production process, and the difference with embodiment 1 is:

[0062] Under the condition of 70°C, the Chinese prickly ash was softened in a softening machine for 10 minutes. Soften the pepper skin and shell, and remove bitter, astringent and other odors as well as some volatile oils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com