Splitted and equalized combined gas and water forced cross-flow cleaning tubular submerged membrane unit

A membrane assembly, submerged technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of complicated disassembly and assembly, hardened membrane core, difficult to clean, etc., to achieve efficient cleaning and overcome dirt. The effect of hardening and slowing down dirt clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

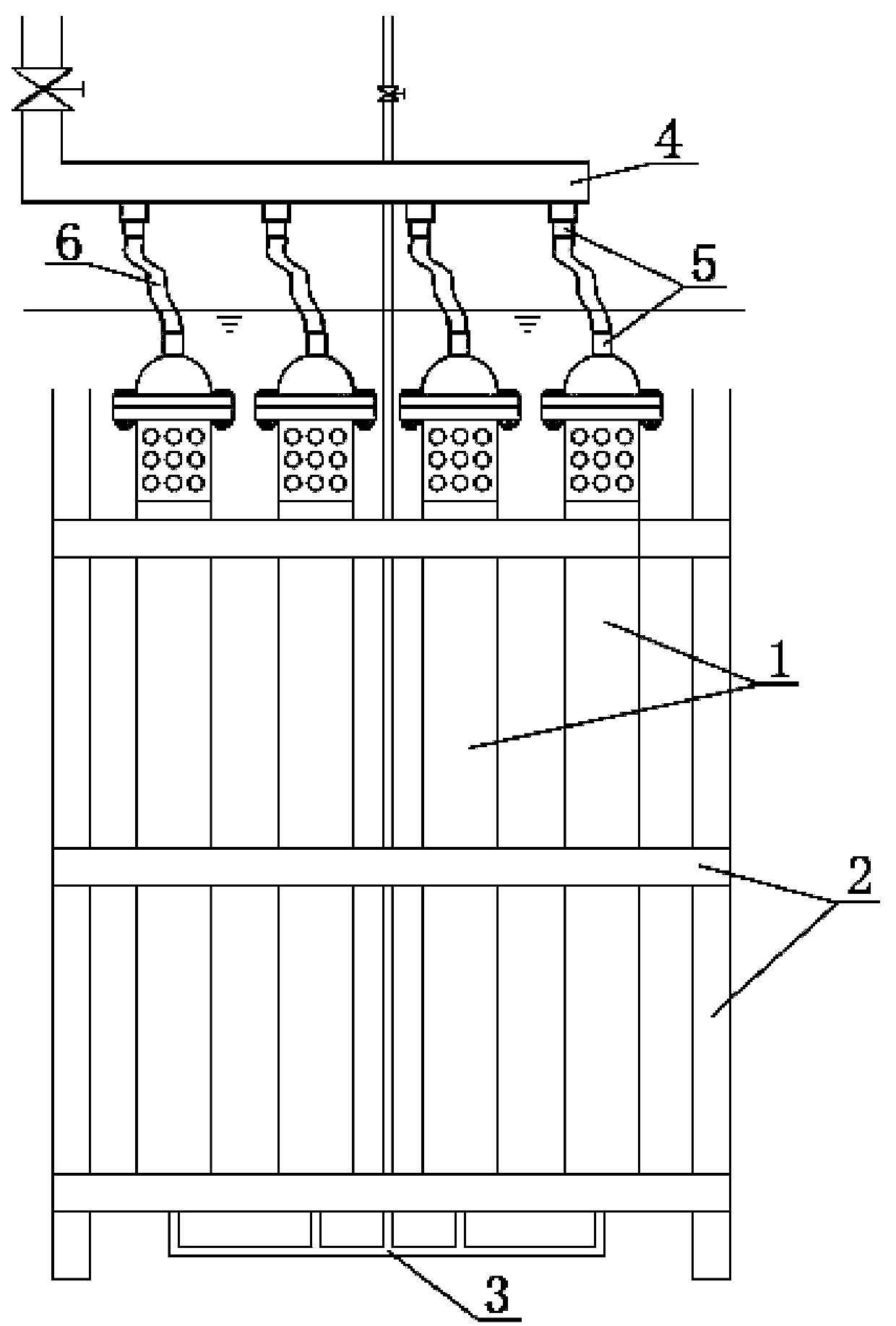

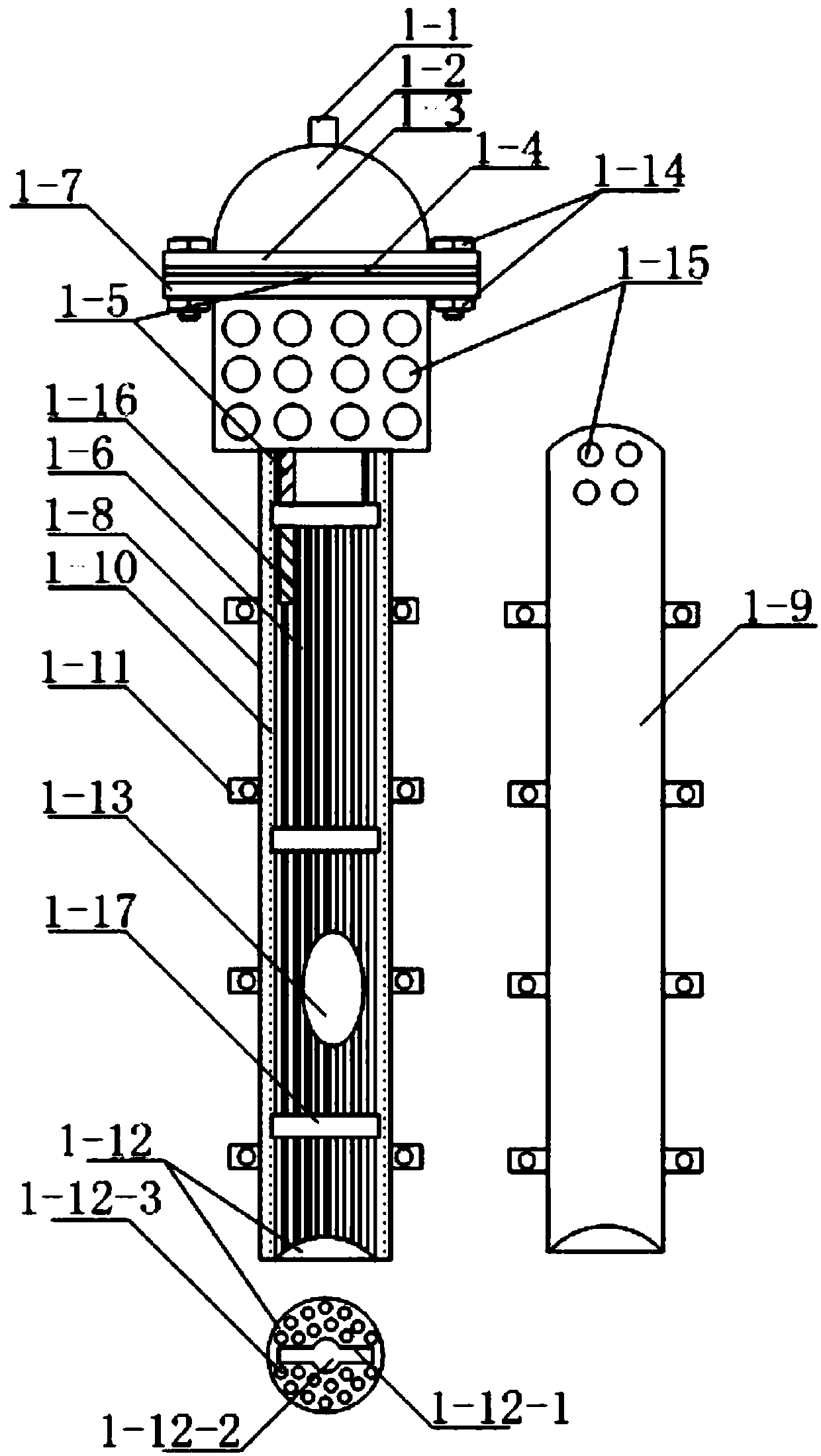

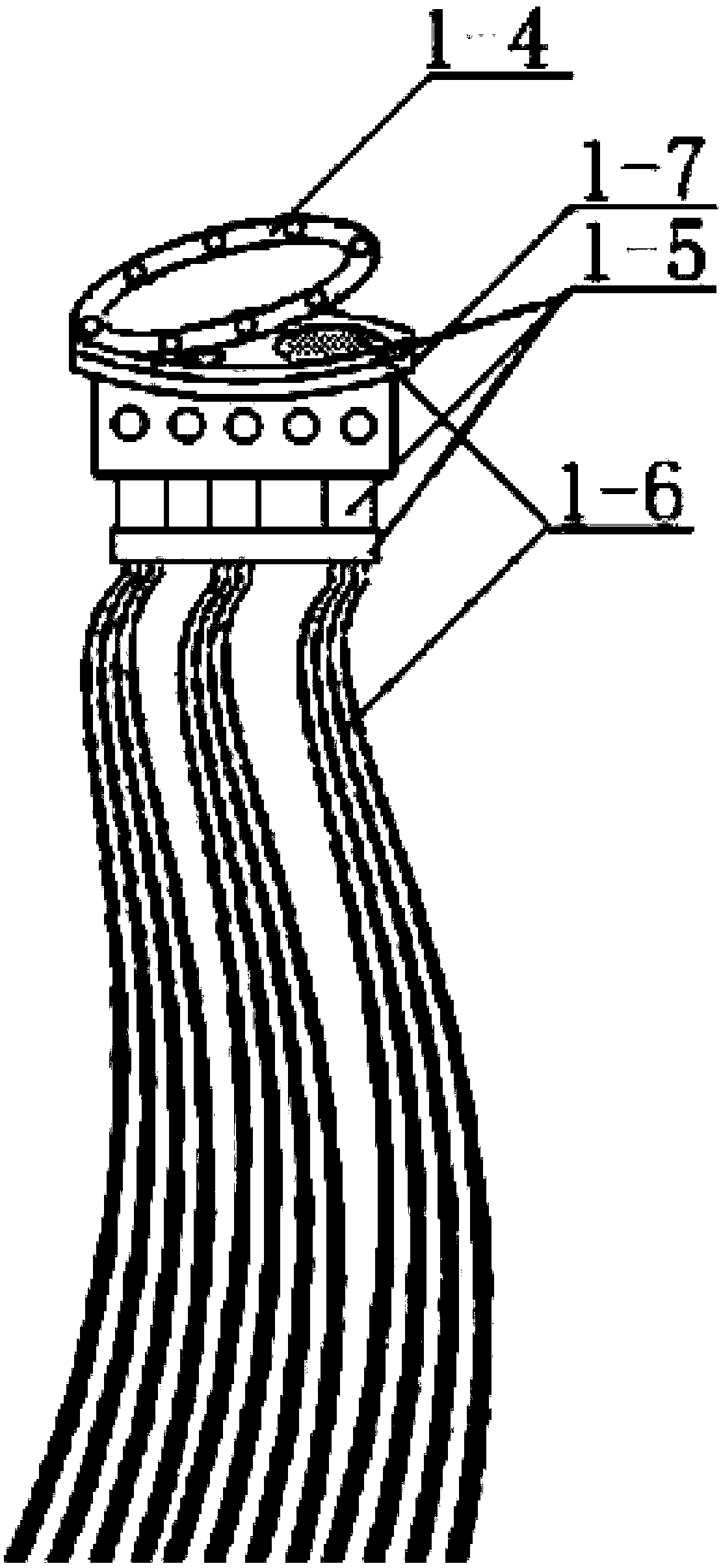

[0042] as attached figure 1 to attach Figure 4 shown

[0043] The present invention provides a tubular submerged membrane unit for beam-splitting, equal sharing and combined air-water forced flow cleaning, including a membrane tube 1, a bracket structure 2, an air inlet pipe 3, a water collection pipe 4, a connecting pipe head 5 and a flexible connecting pipe 6 ; The membrane tube 1 includes a water outlet head 1-1, a half-round cap 1-2, a flange piece 1-3, a sealing gasket 1-4, a membrane bundle connector 1-5, and a hollow fiber membrane bundle 1-6 , flange two 1-7, semi-cylindrical cylinder one 1-8, semi-cylindrical cylinder two 1-9, sealing strip 1-10, fastening connector 1-11, two semicircular mesh bottom plates 1- 12. The guide tube 1-13 and bolts and nuts 1-14; the bolts and nuts 1-14 connect the flange piece 1-3, the gasket 1-4, the membrane bundle connector 1-5 and the method Blue pieces 1-7 are fastened together sequentially from top to bottom; said semi-cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com