Forging mold

A forging and model technology, applied in the field of forging models for manufacturing, can solve the problems that the material cannot be spread over the model, the hardness of the workpiece is insufficiently reduced, the fluidity of the model material is reduced, etc. The effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

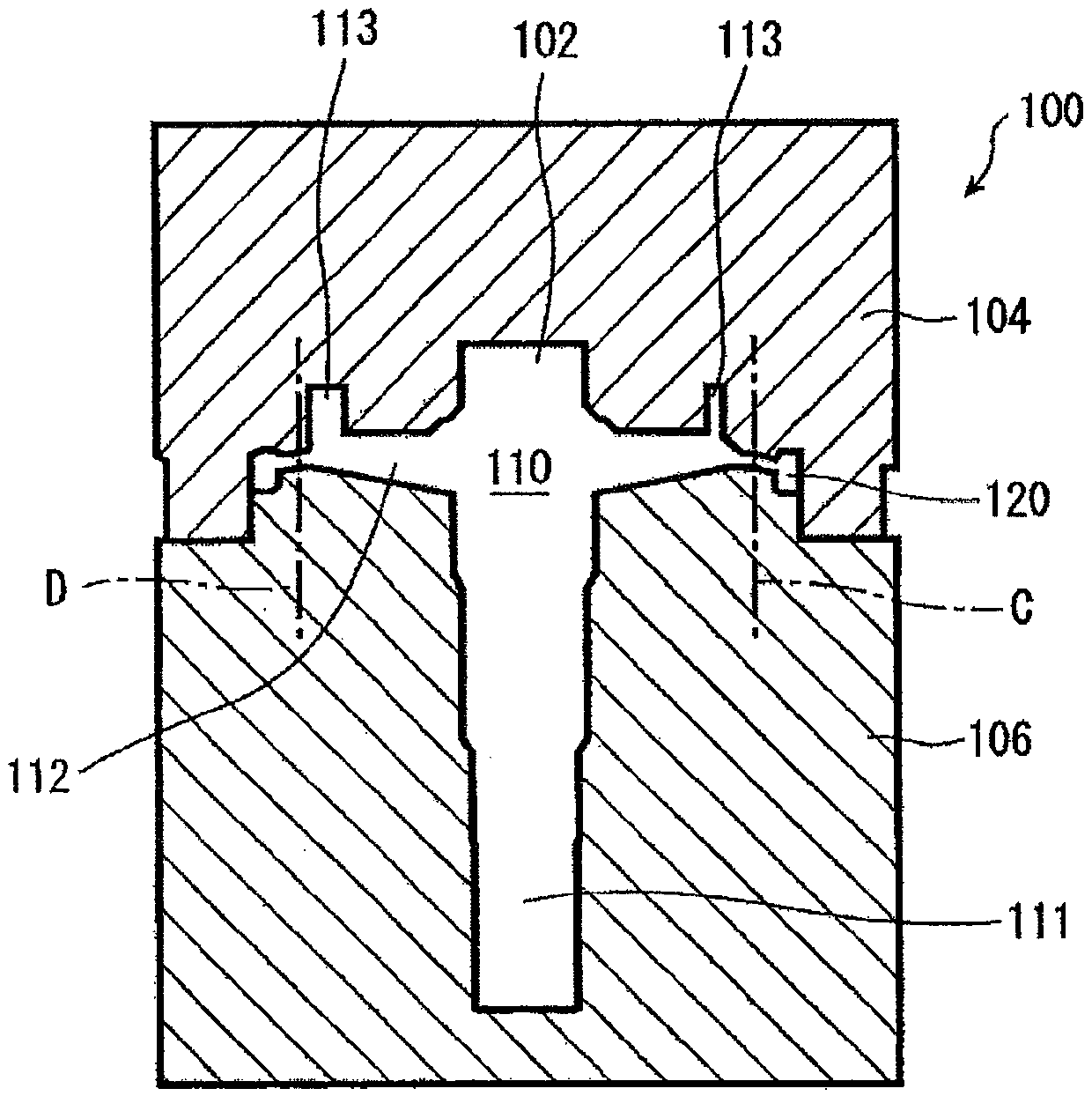

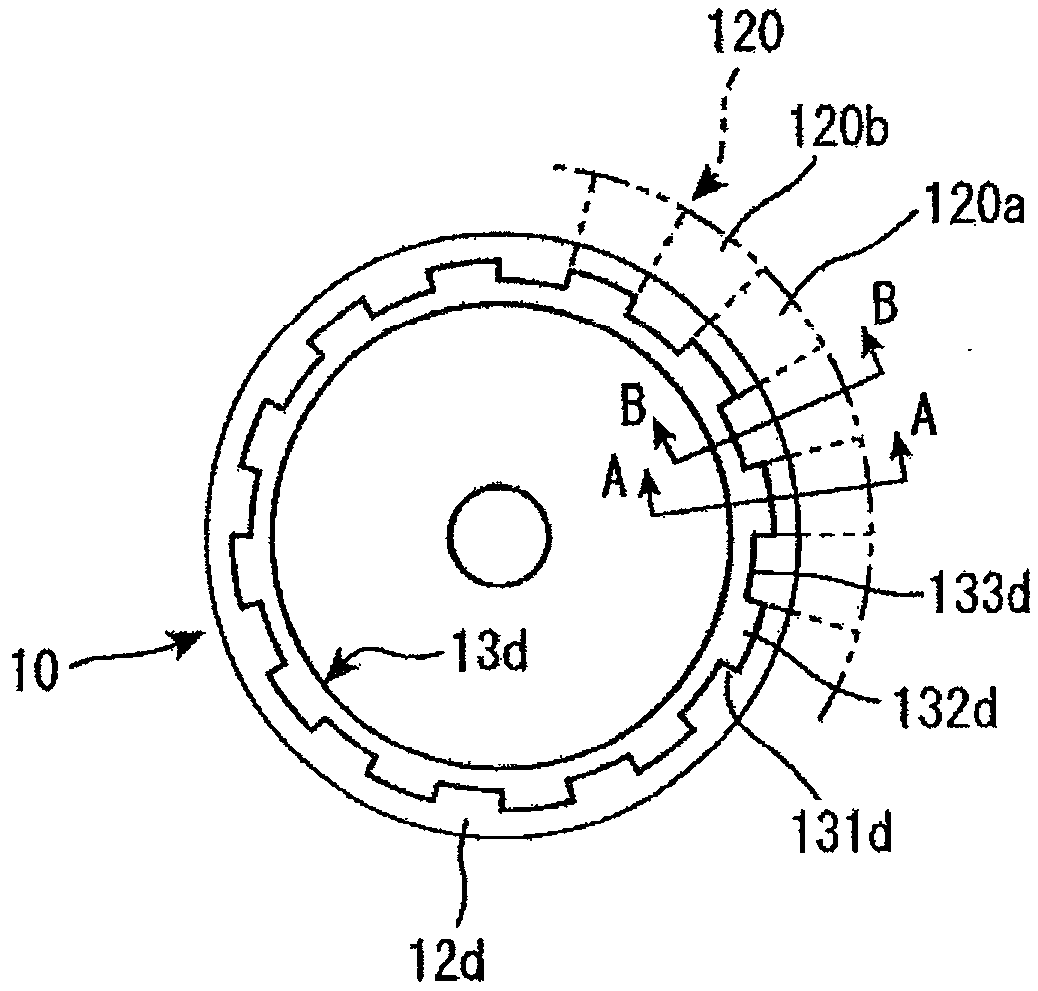

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0039] In addition, the embodiments shown below are merely examples, and various modifications and technical applications not explicitly described in the following embodiments are not excluded.

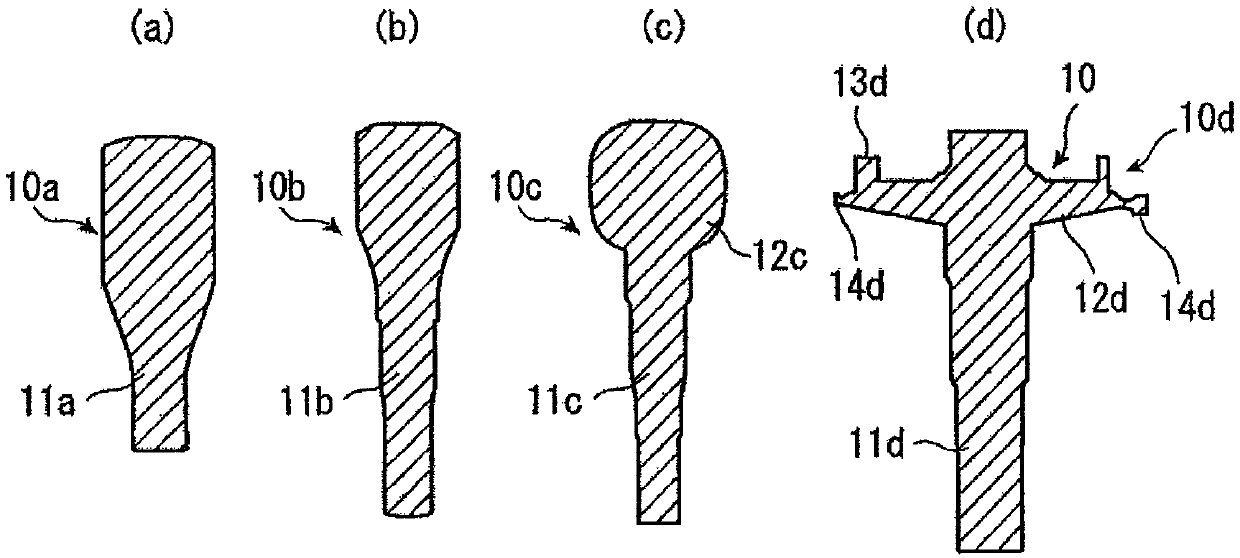

[0040] refer to figure 1 The process of machining a workpiece to manufacture a pulley shaft will be described.

[0041] First, as a pre-forging process, an unillustrated columnar workpiece made of high Si steel is heated to 1120° C. to 1160° C. (subthermal forging).

[0042] Afterwards, the forging process of the first process is carried out on the heated cylindrical workpiece to form a figure 1 (a) shows the first workpiece 10a with the minor axis 11a.

[0043] Next, the forging process of the second step is performed on the first workpiece 10a to form a figure 1 (b) shows the second workpiece 10b with the major axis 11b.

[0044] Next, the forging process of the third st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com