Cold-pressing casting device

A technology of cold pressing and strengthening device, applied in the field of cold pressing casting device, can solve the problems of difficult disassembly and repair, high maintenance cost and high installation cost, and achieve the effects of low production cost, good cold pressing effect and strong driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

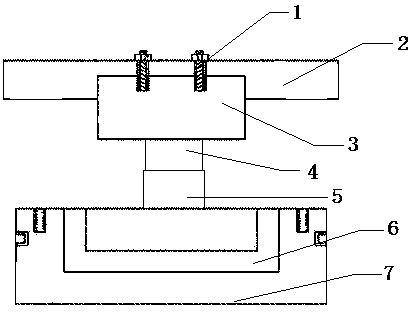

[0012] This embodiment provides a cold die casting device, which is characterized in that: the cold die casting device includes a reinforcement device (1), an upper top plate (2), a pressing block (3), a lifting column (4), a driving cylinder (5), mold (6), base (7);

[0013] Among them: it consists of a pressing block (3), a mold (6) and a drive cylinder (5), the pressing block (3) is set and installed on the lower side of the upper top plate (2) through the reinforcement device (1), and the mold (6) is fixedly installed On the base (7), the upper top plate (2) and the bottom plate (7) are installed and connected through the lifting column (4) driven by the drive cylinder (5).

[0014] The drive cylinder (5) can be a hydraulic drive cylinder or a pneumatic cylinder, and the lifting column (4) is a high-strength steel column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com