Variable diameter pipe type positioning device

A technology for positioning devices and diameter tubes, which is applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as parts falling off, affecting processing accuracy, and easily causing safety accidents, so as to solve processing problems, ensure processing accuracy, and reduce processing costs. and the effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

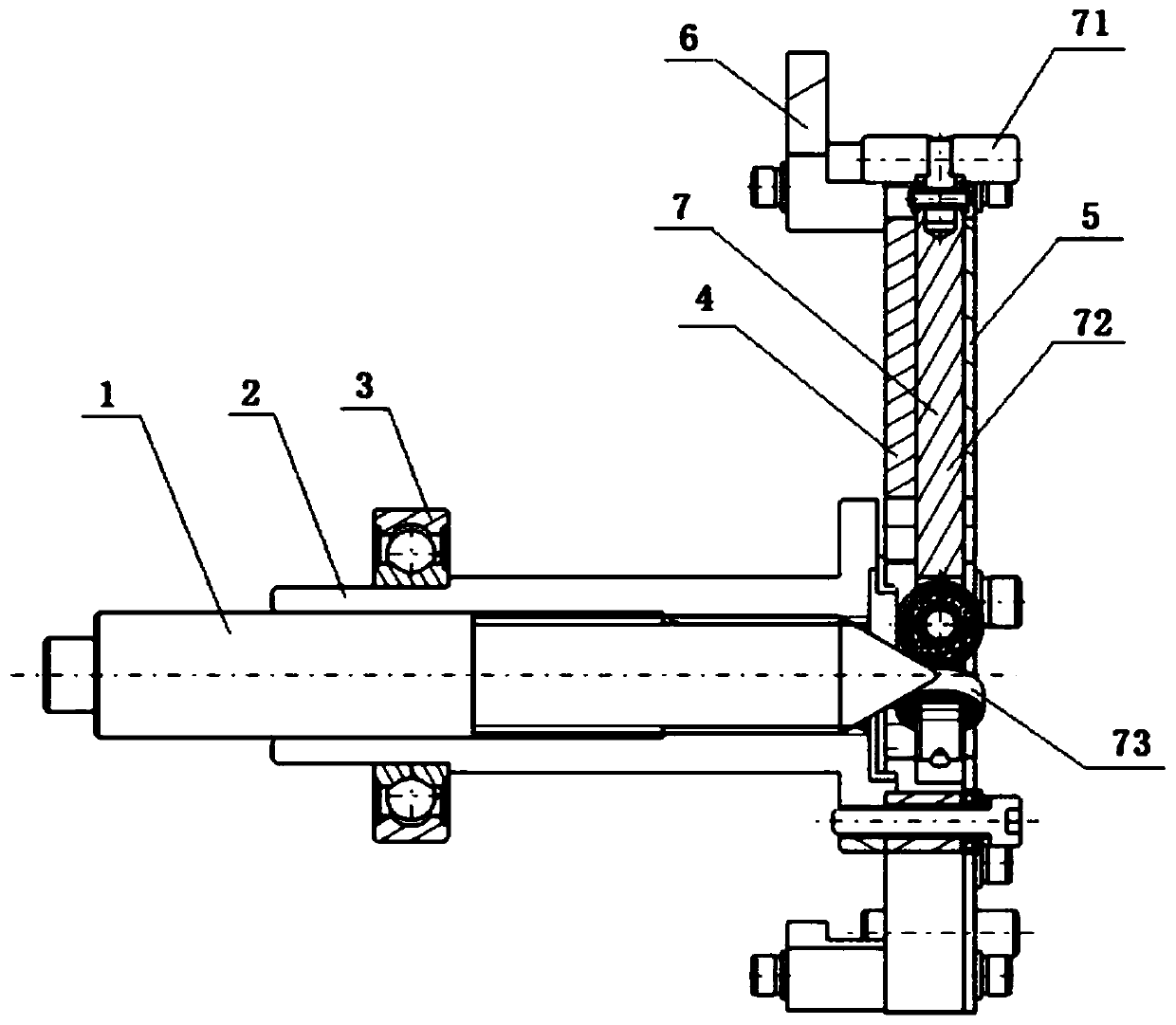

[0019] The following is attached Figure 1-5 The present invention will be further described in detail with specific examples, and the specific examples described here are only used to explain the present invention, and are not intended to limit the present invention.

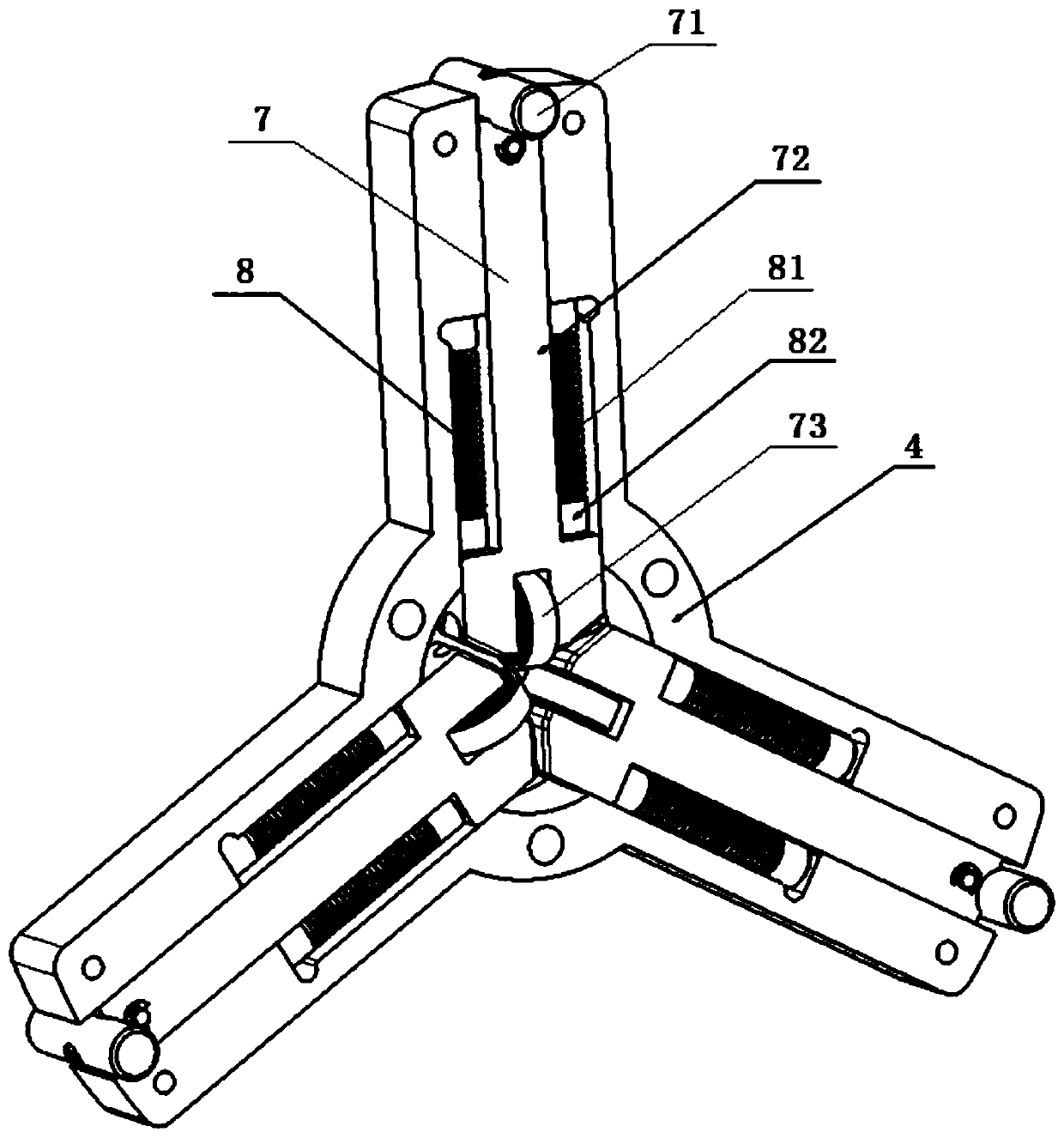

[0020] Refer to attached Figure 4 As shown, the telescopic positioning rod 7 includes a positioning shaft 71, a connecting rod 72, and a passive guide body 73. The positioning shaft 71 is fixedly connected to one end of the connecting rod 72, and the center line of the positioning shaft 71 is connected to the power push rod. 1 parallel to the central line, the passive guide body 73 is fixedly connected to the other end of the connecting rod 72, and the passive guide body 73 is arranged at the center hole of the base body 4.

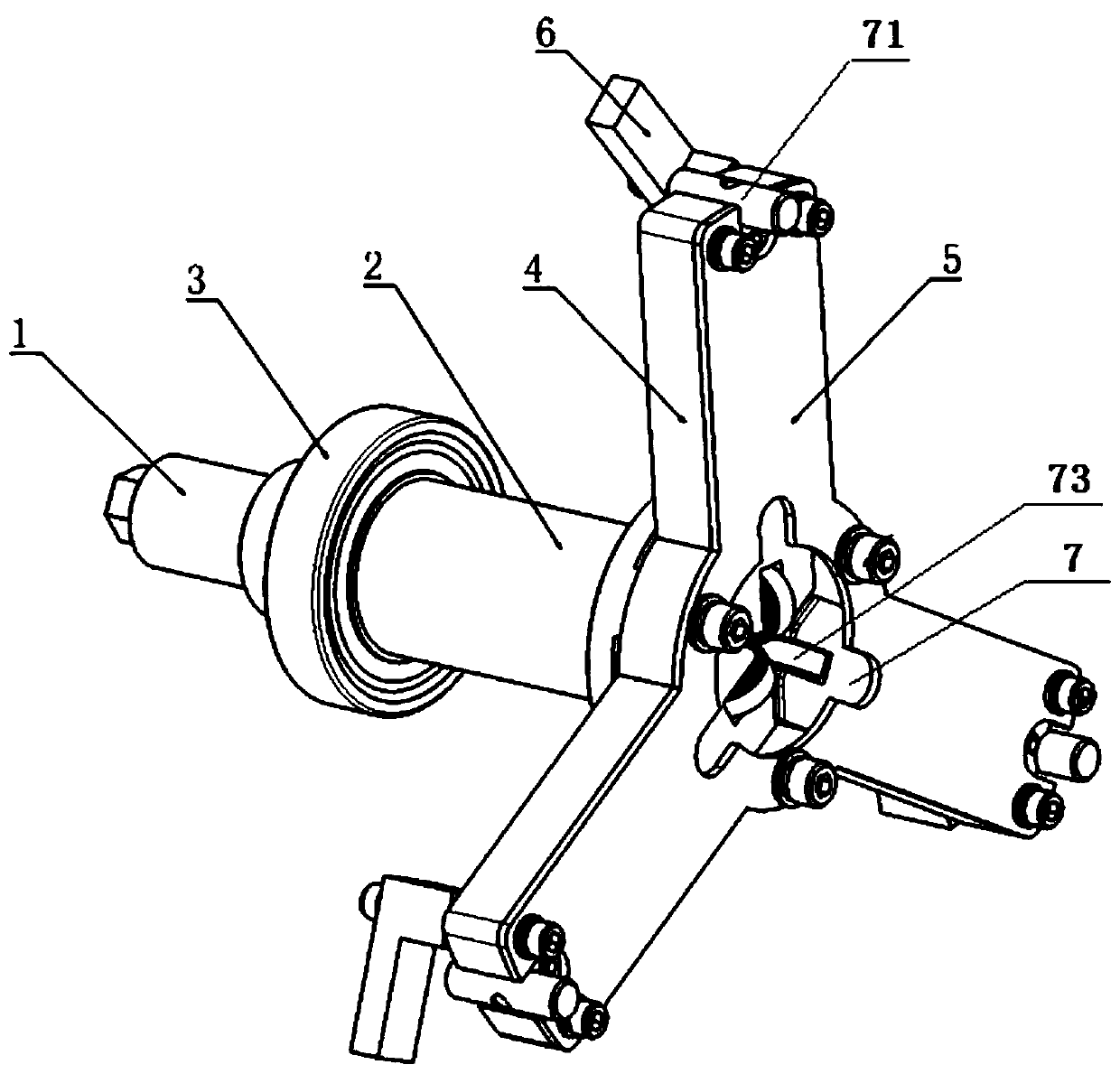

[0021] Refer to attached Figure 1-3 As shown, a variable-diameter pipe positioning device includes: a power push rod 1, a connecting sleeve 2, a base body 4, a gland 5, a telescopic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com