Modularized space multi-stable configuration-varying robot

A multi-stable and modular technology, applied in the field of robotics, can solve the problems of rapid decay of mechanical properties of soft materials, sensitive to ambient temperature and humidity, and difficulty in achieving large variable stiffness ratios, so as to reduce the difficulty of control and reduce the difficulty of control. Usability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

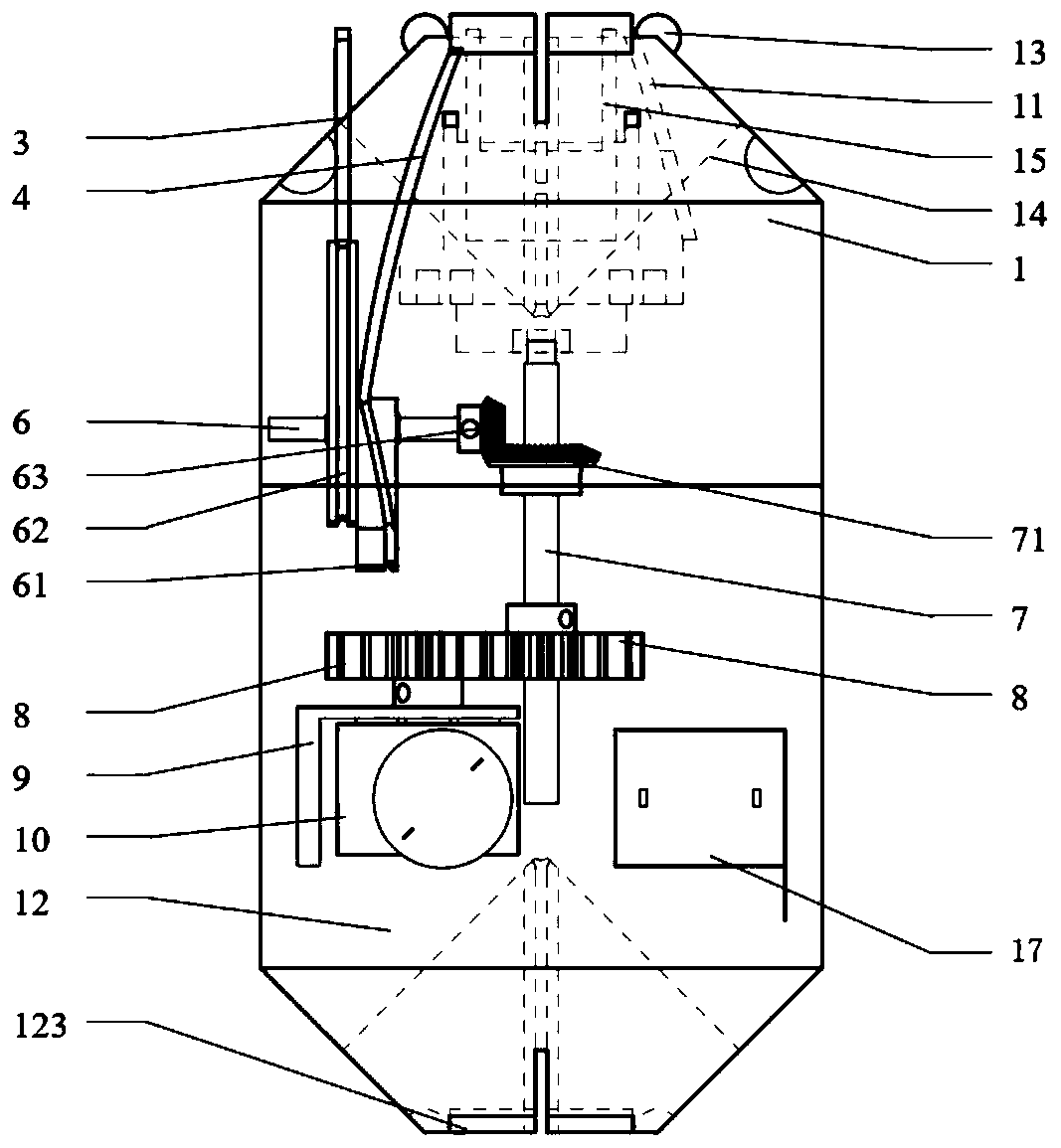

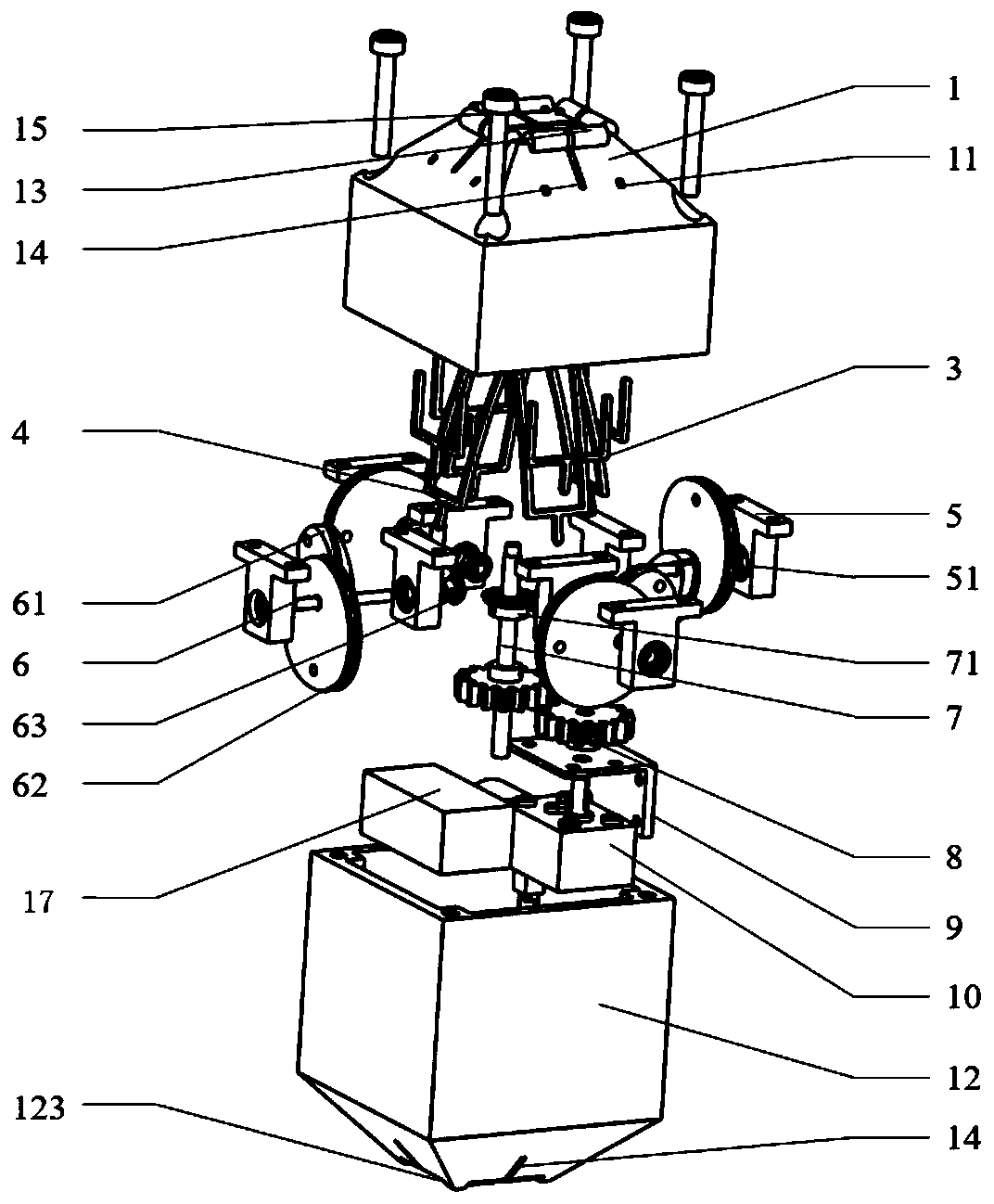

[0043] like figure 1 , figure 2 As shown, the upper half shell 1 of the main body and the lower half shell 12 of the main body are both a decahedron shell-shaped structure composed of a square prism and a square truss, and are connected by four screws 2 to form a 14-sided unit shape structure .

[0044] The inside of described main body lower half shell 12 is equipped with power supply 17 and motor support 9, and motor support 9 installs reduction motor 10; The reduction motor 10, the spur gear transmission group, the bevel gear transmission group, and four sets of camshafts 6 form a single-input-four-output bevel gear transmission.

[0045] The two spur gears 8 form a spur gear train.

[0046] The second bevel gear 71 and the four first bevel gears 63 form a bevel gear transmission set.

[0047] The inside of the upper half shell 1 of the main body is installed with 4 groups of centering roller push rod disc cam machines composed of bearing housing 5, camshaft 6, linear ...

Embodiment 2

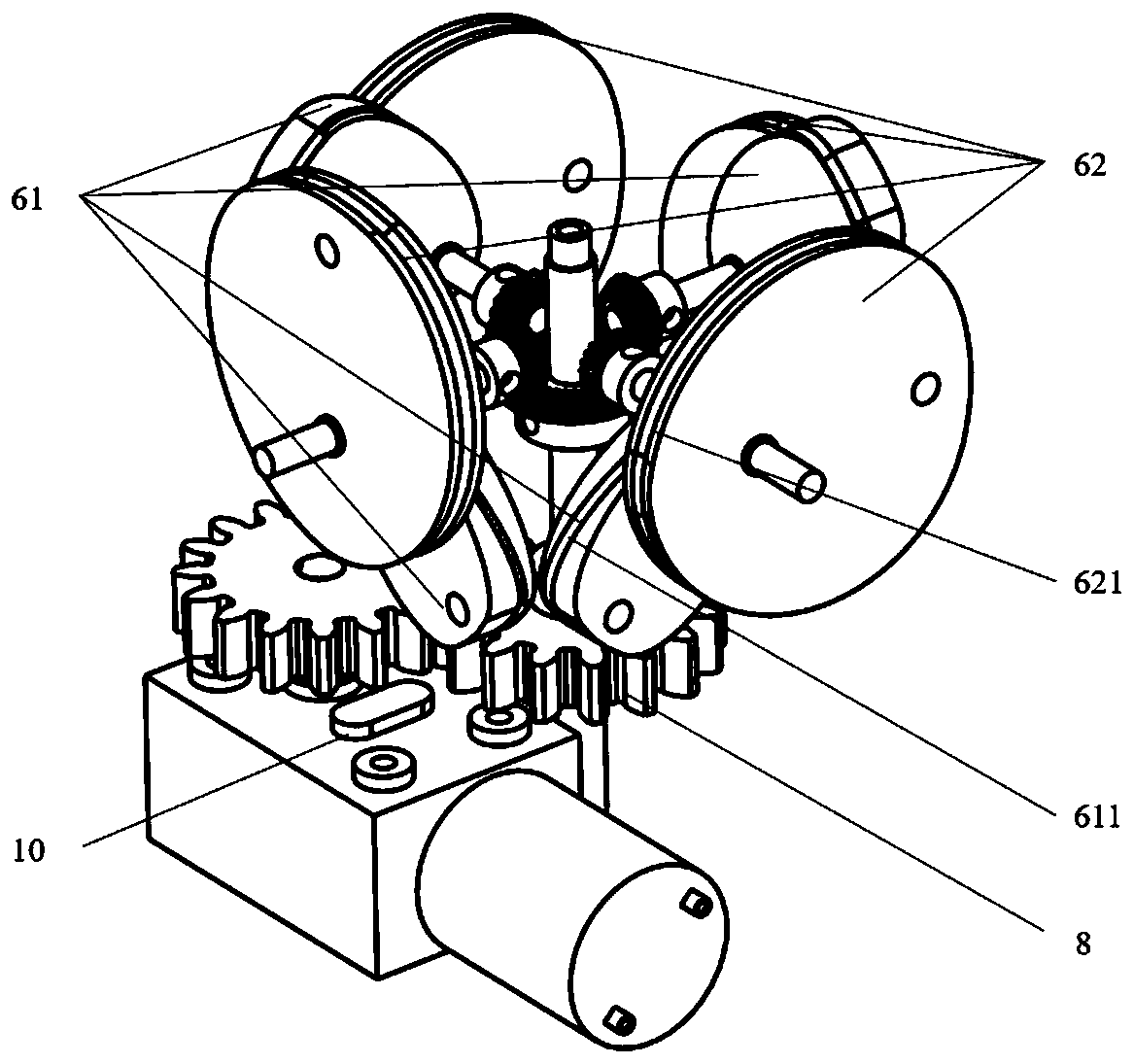

[0050] like image 3 As shown, the single-input and four-output bevel gear transmission includes at least four camshafts 6 , transmission shafts 7 , spur gears 8 , and reduction motors 10 . The camshaft 6 includes a first cam 61, a first cam guide groove 611, a second cam 62, a second cam guide groove 621, and a first bevel gear 63, and the transmission shaft 7 includes a second bevel gear 71 and a spur gear 8;

[0051] The geared motor 10 is a 24v DC geared motor, model JGY370, with a rotating speed of 10 rpm. The motor adopts a worm gear to reduce the torque, and has a large torque and strong self-locking ability.

[0052] Described two spur gears 8 form spur gear transmission group, and two spur gears are identical, all select 2 molds for use, 16 teeth.

[0053] The second bevel gear 71 and four first bevel gears 63 form a bevel gear transmission group, the second bevel gear 71 is selected with 0.5 mold 40 teeth, and the first bevel gear 63 is selected with 0.5 mold 20 tee...

Embodiment 3

[0056] like Figure 4 As shown, the center roller push rod disc cam mechanism at least includes the upper half shell 1 of the main body, the linear push rod 3, the arc push rod 4, the bearing seat 5, and the camshaft 6. The upper shell 1 of the main body contains four linear push rod guide grooves 11 and four arc push rod guide grooves 15, the linear push rod 3 includes the upper end of the linear push rod and the lower end of the linear push rod, and the arc push rod 4 includes arc The upper end of the push rod and the lower end of the arc push rod, the bearing housing 5 includes a bearing 51 , and the camshaft 6 includes a first cam 61 , a first cam guide groove 611 , a second cam 62 , and a second cam guide groove 621 .

[0057] In the camshaft 6, the first cam 61 and the second cam 62 are distributed with an angle difference of 135 degrees. The first cam guide groove 611 of the first cam 61 is rollingly connected with the arc push rod lower end of the arc push rod 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com