Bean curd dicing and arranging processing device

A processing device and dicing technology, applied in metal processing and other directions, can solve the problems of high cost, inability to complete automatic layout, and difficulty in mechanical cutting, and achieve the effect of reducing waste problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

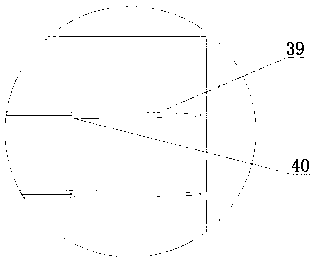

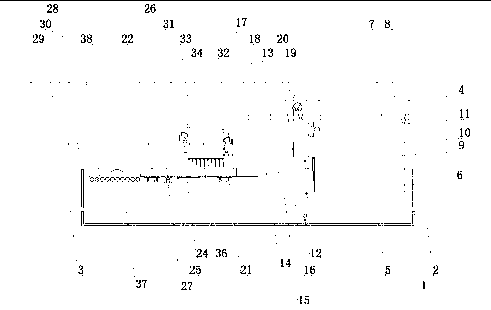

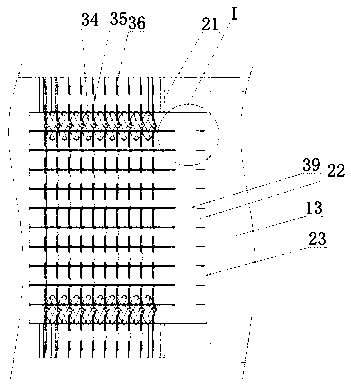

[0030] Example: A device for processing and arranging tofu cut pieces, the main structure includes a tank 1 which is a rectangular tank, one end of the tank 1 is provided with a water inlet 2, and the other end of the tank 1 is provided There is a water outlet 3, and water is injected into the tank 1 to form a directional water flow from front to back. A mounting frame 4 for installing transmission equipment is provided above the tank 1 and runs along the front end of the water inlet 2 of the tank 1 to The rear end of the water outlet 3 is provided with:

[0031] Pusher assembly-The pusher assembly includes a fixed plate 5 for placing tofu monoliths, the fixed plate 5 is fixed in the tank 1, and the front end of the fixed plate 5 is provided with a vertical pusher Plate 6, above the fixed plate 5 is provided with a pusher guide 7 and a pusher screw 8, the pusher guide 7 and the pusher screw 8 are installed on the mounting frame 4, the pusher guide 7 The slider and the nut on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com