LED bulb

A technology for LED light bulbs and lamp housings, which is applied in the direction of lampshades, damage prevention measures for lighting devices, cooling/heating devices for lighting devices, etc., and can solve the problem of small contact surface space between light-emitting units and lamp housings, luminosity and lifespan of LED lamps Problems such as drop and poor heat conduction speed at the junction of components, etc., to facilitate the spraying of plastic layers, avoid local overheating, and reduce waste and leftovers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

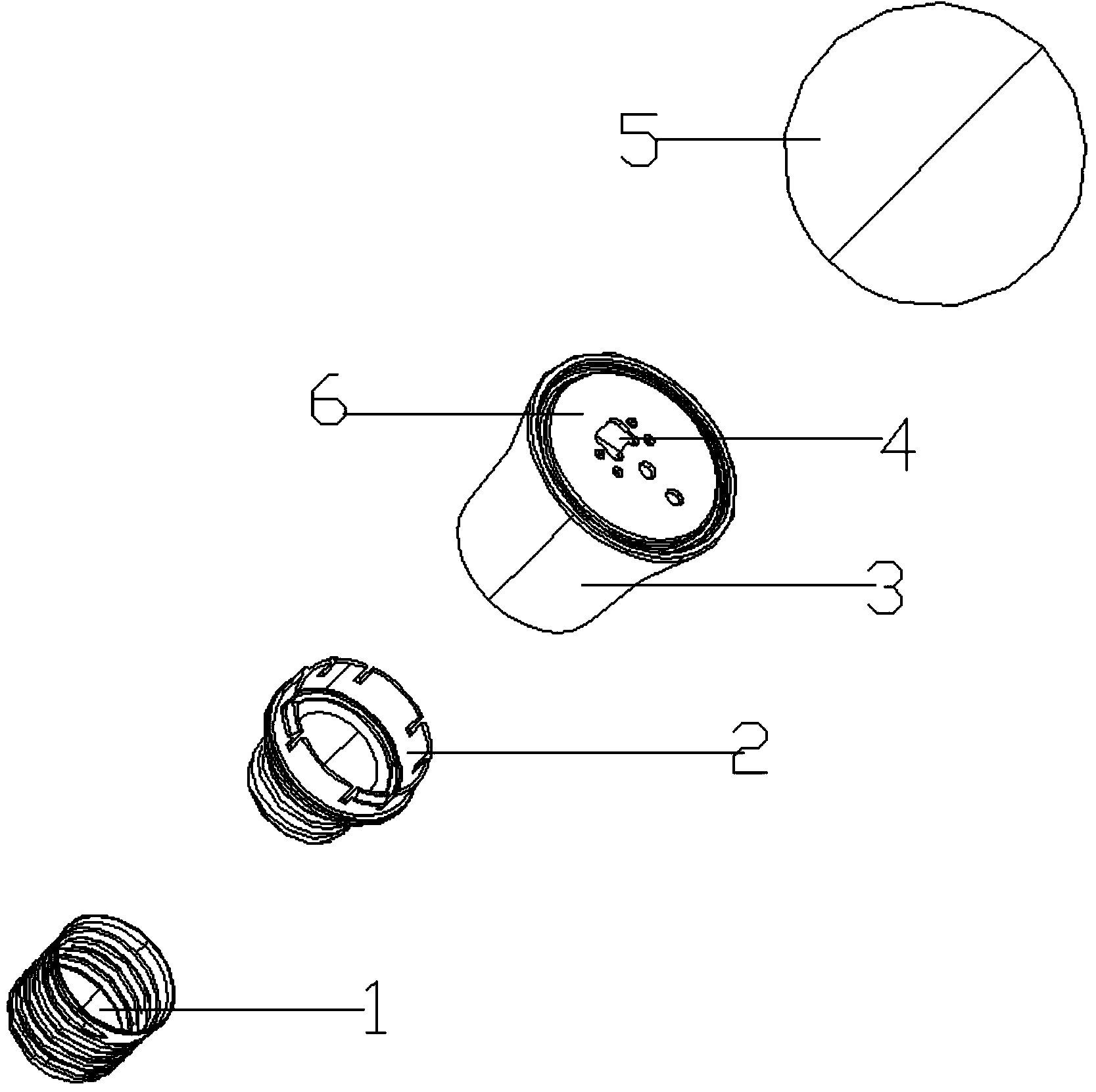

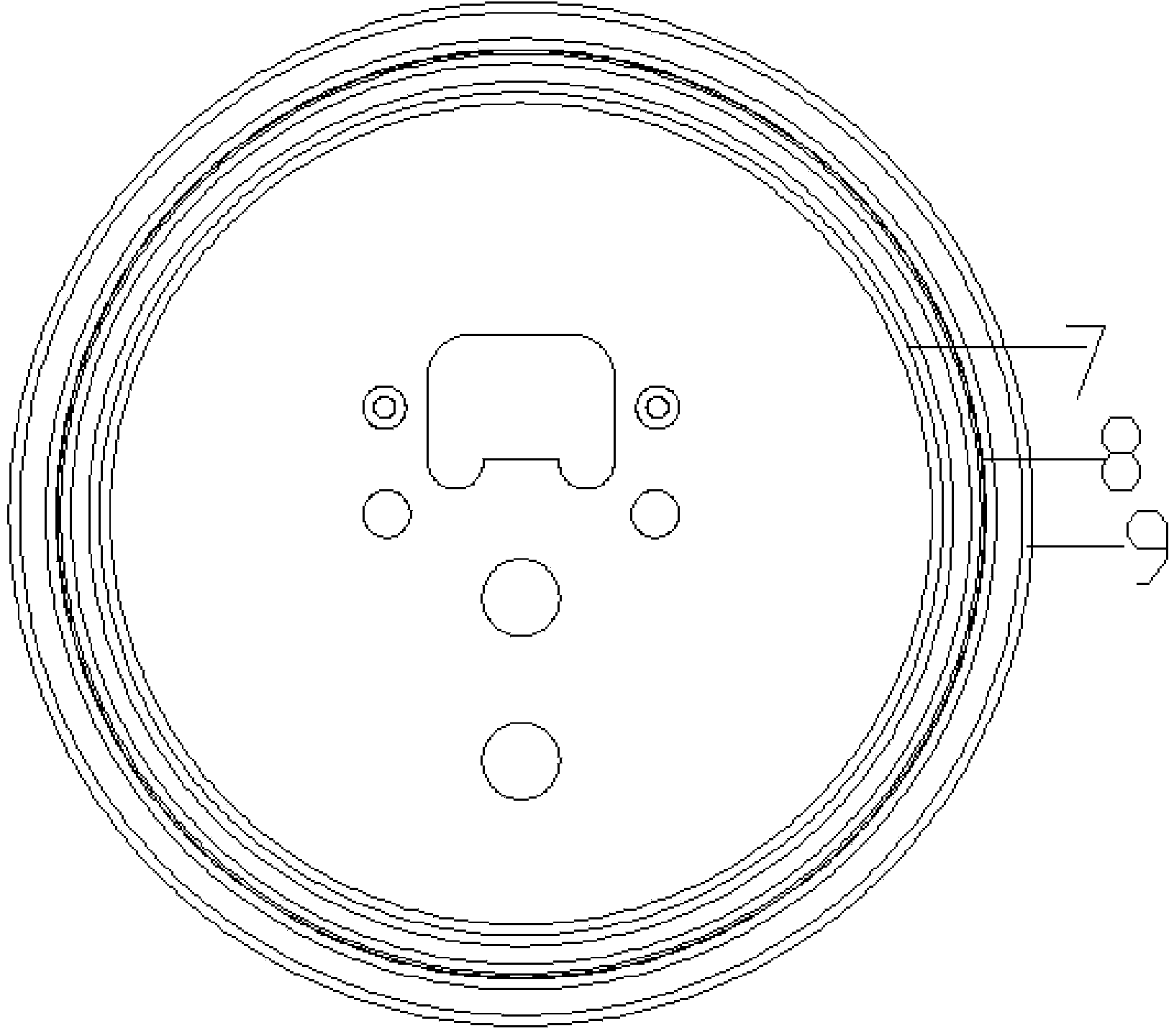

[0038] The invention discloses an LED light bulb, which comprises a bottom shell 1, a base 2, a lamp shell 3, a light-emitting unit 4, and a lampshade 5. The bottom shell 1 is connected with the base 2 through threads, the lamp shell 3 is a circular truncated structure, and the lamp shell 3 It is an overall integrated structure, the end with a small cross-sectional area is an open structure, the outer edge of the opening structure of the lamp housing 3 is provided with threads, the lamp holder 2 is connected with the lamp housing 3 through threads, and the end with a large cross-sectional area is a closed structure. The bottom of the closed structure of the lamp housing 3 constitutes a bottom plate 6 on which the LED chip of the light emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com