Low-odor low-VOC foaming raw material and material mixing process

A foaming raw material and low-odor technology, applied in the field of foaming materials for automotive interior parts, can solve the problems of large odor, large VOC emissions, and rising costs, and achieve the effects of improving odor, reducing emissions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

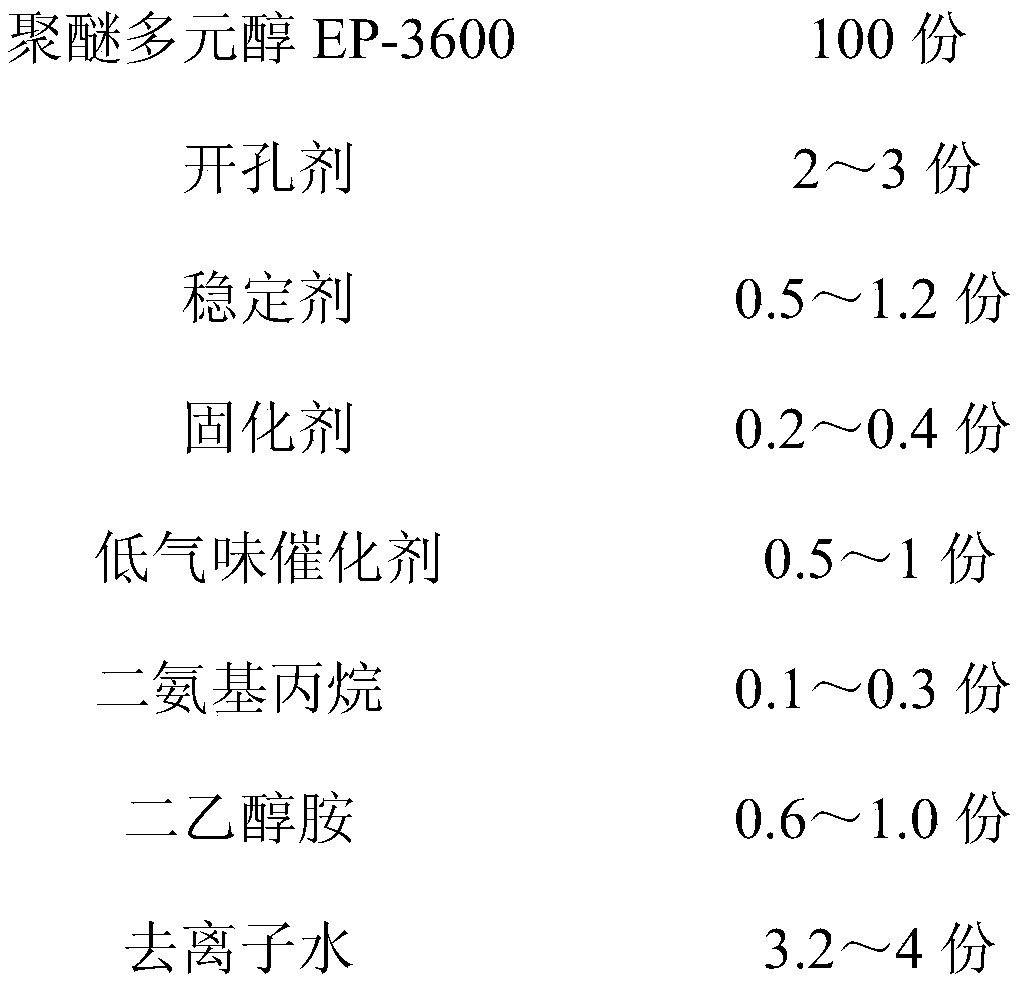

[0033] Embodiment 1 provides a low-odor and low-VOC foaming raw material, which is composed of the following weight fractions: 100 parts of polyether polyol EP-3600, 2.5 parts of cell opener 2048, 0.8 parts of foam stabilizer Agent 8745, 0.3 parts of curing agent ECOADD 317, 0.6 parts of catalyst ECOADD 433, 0.2 parts of diaminopropane, 0.8 parts of diethanolamine, 3.6 parts of deionized water.

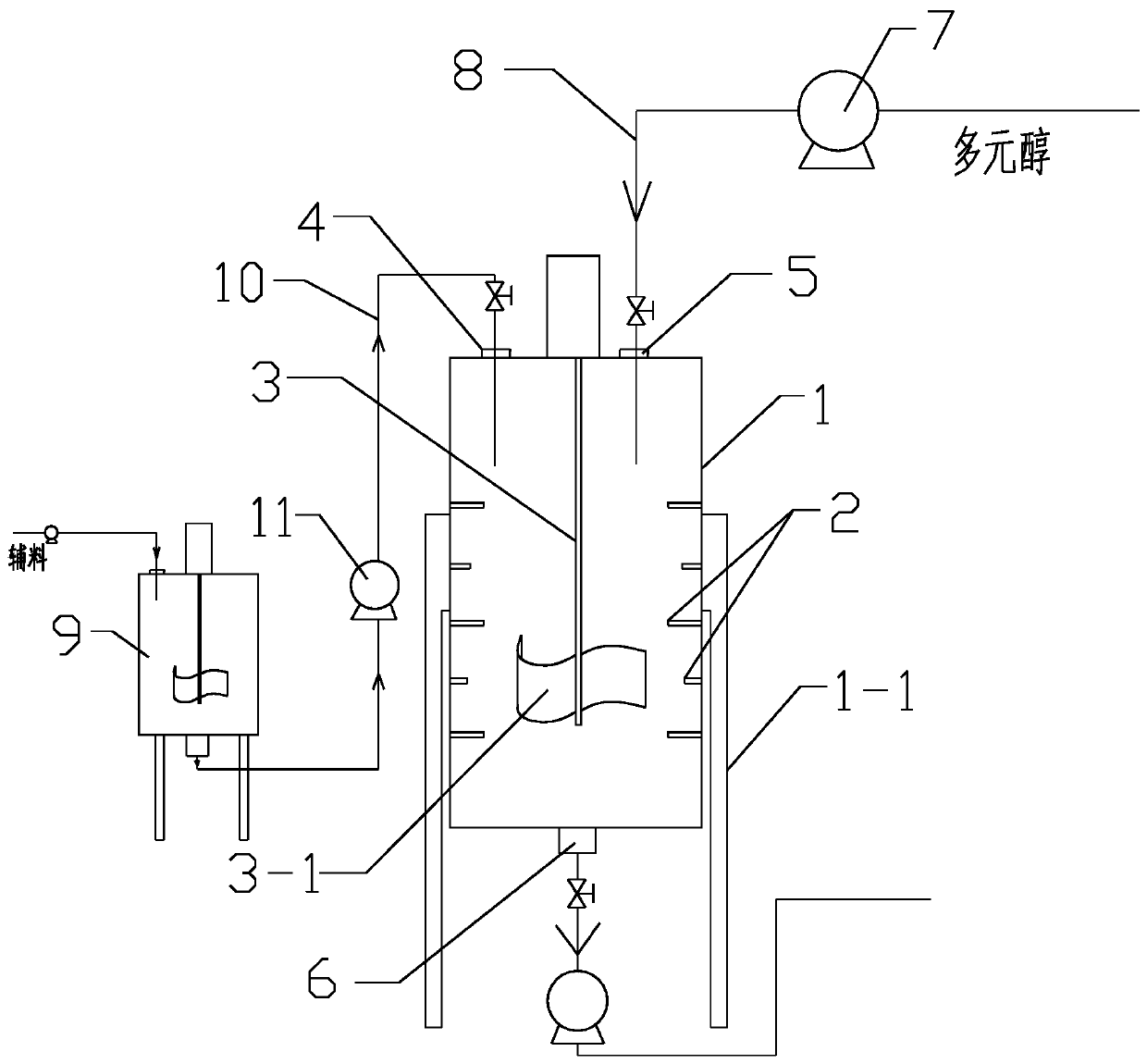

[0034] Add the deionized water in the above formula into the mixing tank 1, and transport 100 parts of polyether polyol EP-3600 into the mixing tank 1 through the polyether feeding pump 7, and stir for 1 hour at the speed of 140r / min , mix it evenly, and the feeding flow rate of polyether polyol EP-3600 is ≥70L / min; 2.5 parts of cell opening agent 2048, 0.8 parts of foam stabilizer 8745, 0.3 parts of curing agent ECOADD 317, 0.6 parts Catalyst ECOADD 433, 0.2 parts of diaminopropane, 0.8 parts of diethanolamine, and 3.6 parts of deionized water are added to the raw material barrel, an...

Embodiment 2

[0035] Embodiment 2 provides a low-odor and low-VOC foaming raw material, which is composed of the following weight fractions: 100 parts of polyether polyol EP-3600, 2 parts of cell opener 2048, 1.2 parts of foam stabilizer Agent 8745, 0.2 parts of curing agent ECOADD 317, 0.9 parts of catalyst ECOADD 433, 0.1 parts of diaminopropane, 1 part of diethanolamine, 4 parts of deionized water.

[0036] Add the deionized water in the above formula into the mixing tank 1, and transport 100 parts of polyether polyol EP-3600 into the mixing tank 1 through the polyether feeding pump 7, and stir at a speed of 240r / min for 0.8 h, mix it evenly, the feeding flow rate of the polyether polyol EP-3600 is ≥70L / min; all the cell opener 2048, foam stabilizer 8745, curing agent ECOADD317, catalyst ECOADD 433, diaminopropane, di Add ethanolamine and deionized water into the raw material barrel, and send them into the auxiliary material mixing tank 9 through the feeding pump, stir for 1.2 hours unde...

Embodiment 3

[0037] Embodiment 3 provides a low-odor and low-VOC foaming raw material, which is composed of the following weight fractions: 100 parts of polyether polyol EP-3600, 3 parts of cell opener 2048, 0.5 parts of foam stabilizer Agent 8745, 0.4 parts of curing agent ECOADD 317, 1 part of catalyst ECOADD 433, 0.3 parts of diaminopropane, 0.6 parts of diethanolamine, 3.5 parts of deionized water.

[0038] Add the deionized water in the above formula into the mixing tank 1, and transport 100 parts of polyether polyol EP-3600 into the mixing tank 1 through the polyether feeding pump 7, and stir for 2 hours at a speed of 400r / min , mix it evenly, the feeding flow rate of the polyether polyol EP-3600 is ≥70L / min; all the cell opener 2048, foam stabilizer 8745, curing agent ECOADD317, catalyst ECOADD 433, diaminopropane, diethanolamine 1. Deionized water is added in the raw material barrel, and is sent into the auxiliary material mixing tank 9 through the feeding pump, stirred for 1.2h un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com