Aqueduct seam water stopping device for water conservancy project

A technology for water conservancy projects and water stop devices, applied in water conservancy projects, marine engineering, artificial waterways, etc., can solve problems such as difficult repair, poor adaptability to temperature changes, water leakage, etc., to reduce water seepage, increase water seepage resistance, and solve the gap between aqueduct The effect of the water stop problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

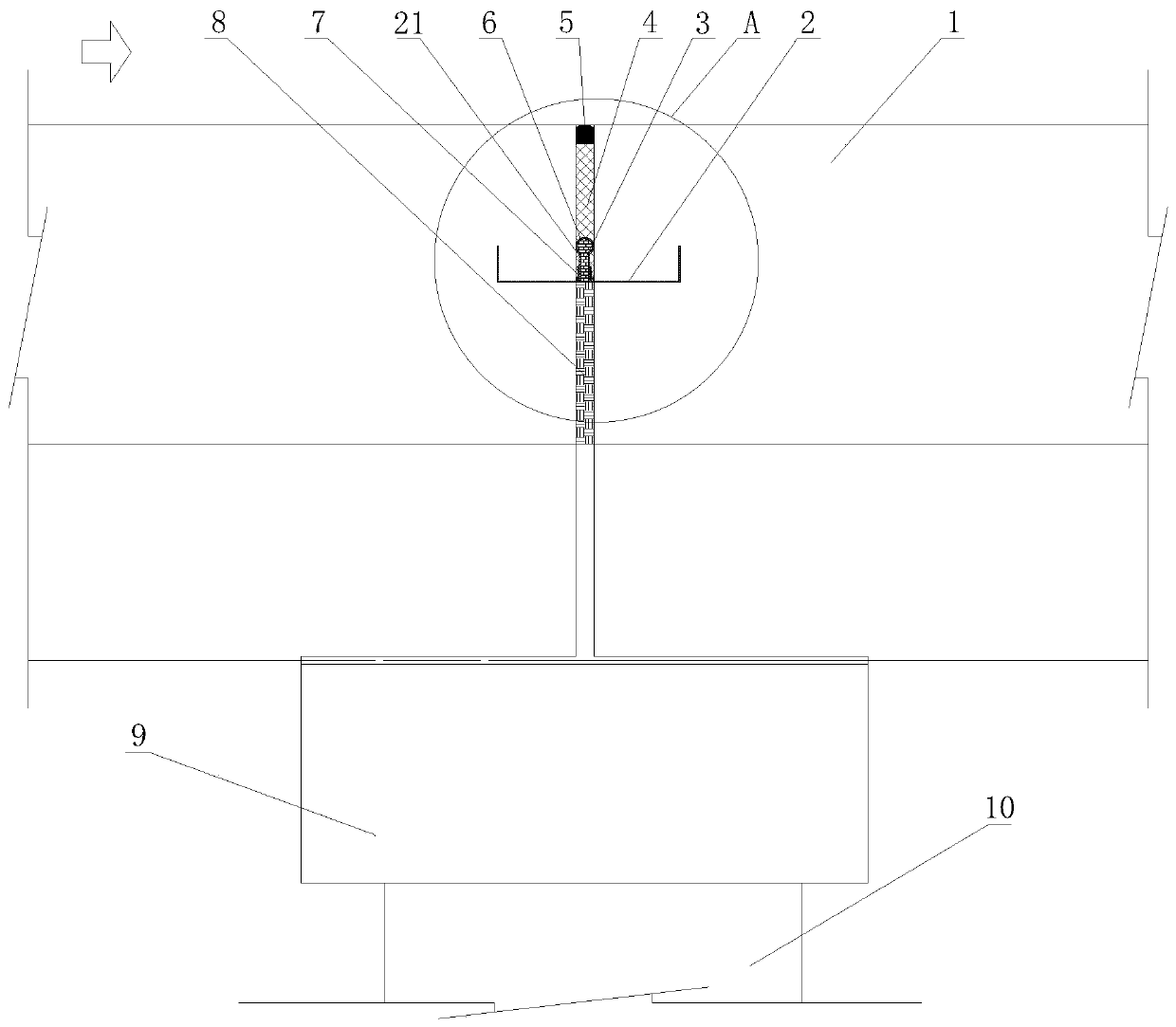

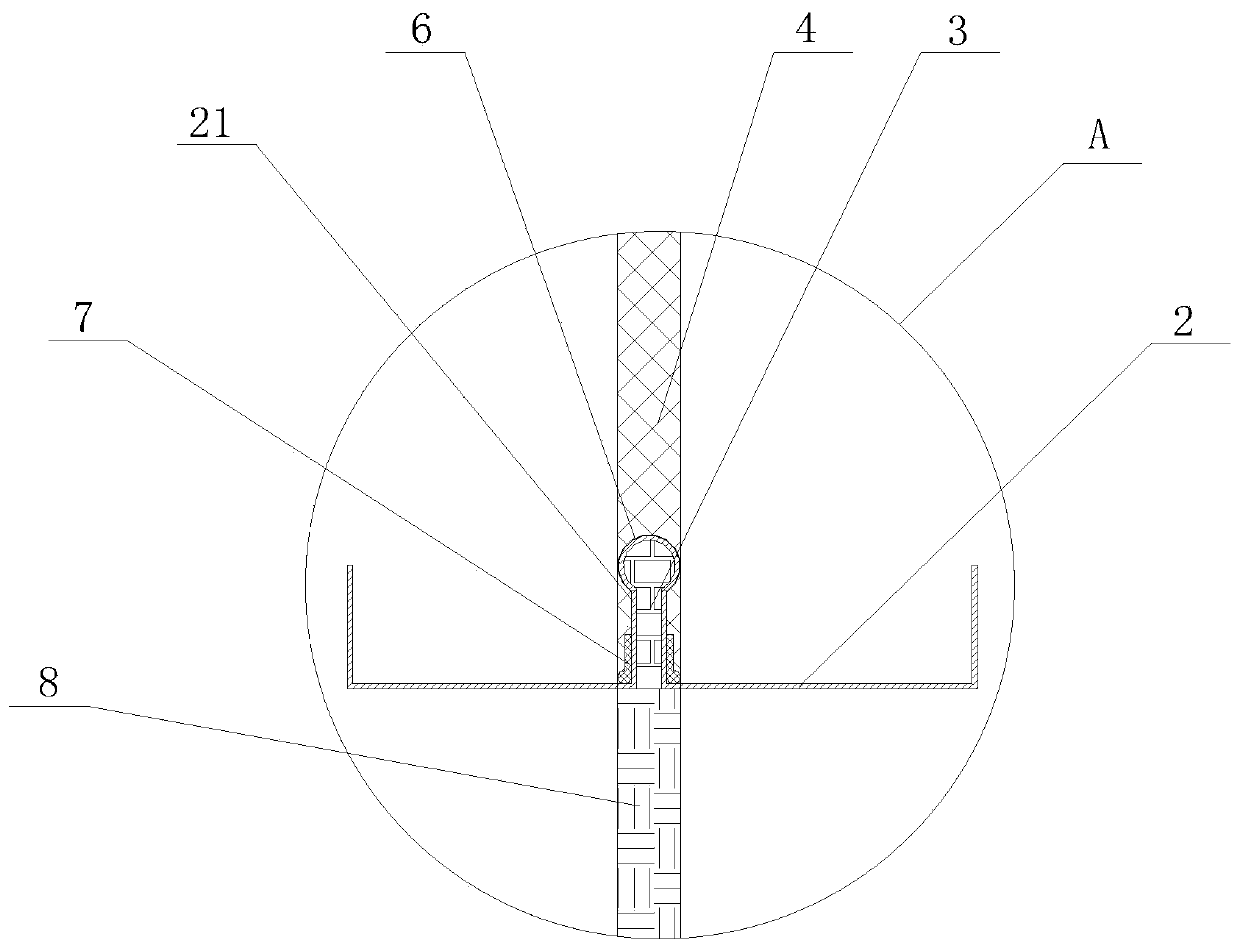

[0017] The technical scheme adopted in this embodiment is as follows: figure 1 , 2 As shown, a water-stopping device for seams between aqueducts used in water conservancy projects is arranged in the seams between adjacent aqueduct bodies 1, and includes a first waterproof structure, a second waterproof structure and a third waterproof structure. The first The waterproof structure includes polysulfide sealing paste 5. The polysulfide sealing paste 5 is arranged at the outermost end of the seam. After the aqueduct body 1 passes through the water, the seam is in direct contact with the water body. The polysulfide sealing paste is an auxiliary anti-seepage material. It has good adhesion to materials such as metal and concrete, and maintains good air tightness and water resistance under continuous expansion, vibration and temperature changes. The second waterproof structure includes an expanded rubber waterstop 4, which is arranged below the sealing paste 5. The expanded rubber wa...

Embodiment 2

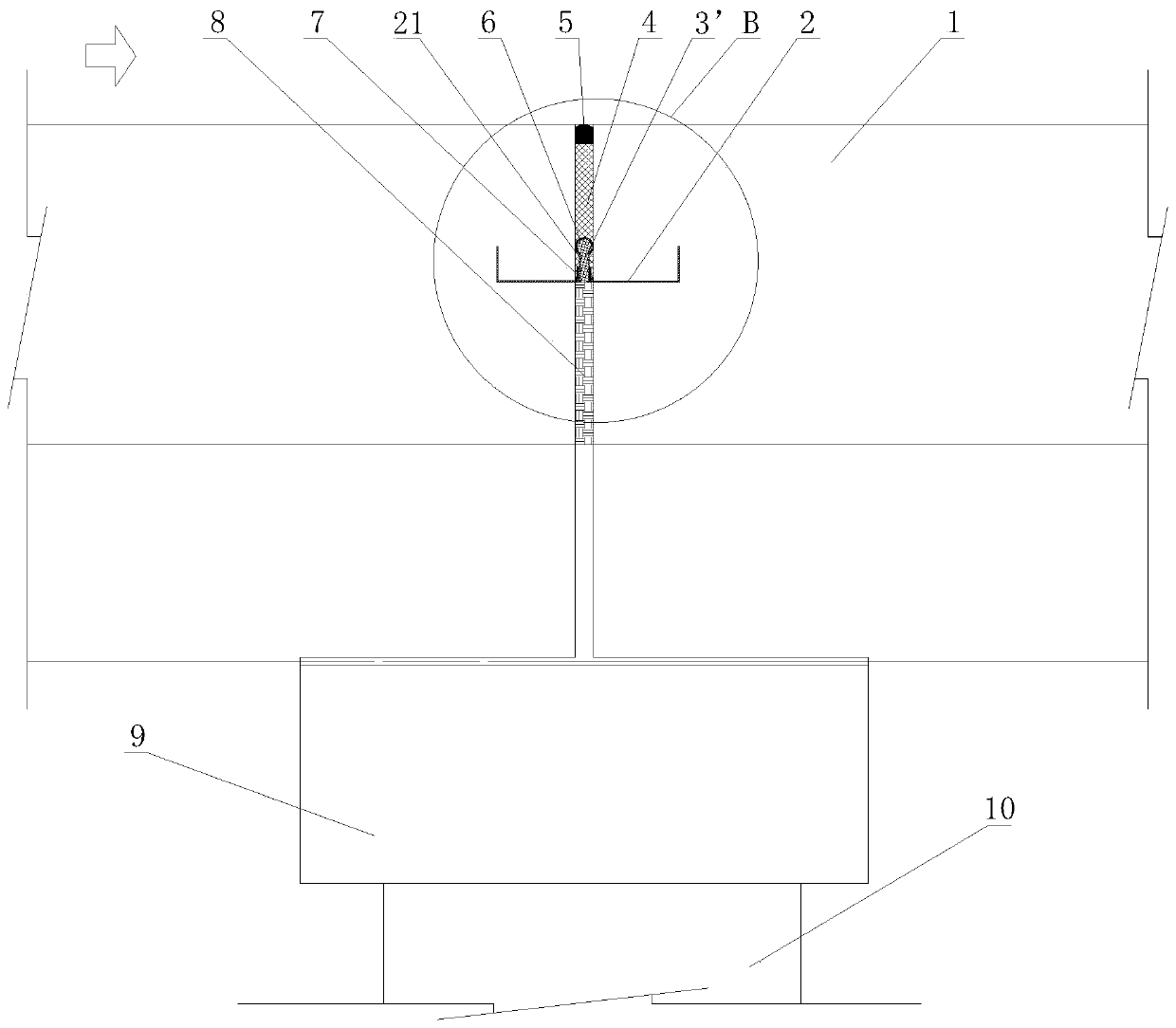

[0022] The technical scheme adopted in this embodiment is as follows: image 3 , 4 As shown, a water-stopping device for seams between aqueducts used in water conservancy projects is arranged in the seams between adjacent aqueduct bodies 1, and includes a first waterproof structure, a second waterproof structure and a third waterproof structure. The first The waterproof structure includes polysulfide sealing paste 5. The polysulfide sealing paste 5 is arranged at the outermost end of the seam. After the aqueduct body 1 passes through the water, the seam is in direct contact with the water body. The polysulfide sealing paste is an auxiliary anti-seepage material. It has good adhesion to materials such as metal and concrete, and maintains good air tightness and water resistance under continuous expansion, vibration and temperature changes. The second waterproof structure includes an expanded rubber waterstop 4, which is arranged below the sealing paste 5. The expanded rubber wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com