Construction method of underground diaphragm wall in a tunnel

A construction method and continuous wall technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as adverse effects on the stability of tunnel structures, abnormal construction, and limited tunnel construction space, and achieve simple structure and convenient construction , flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

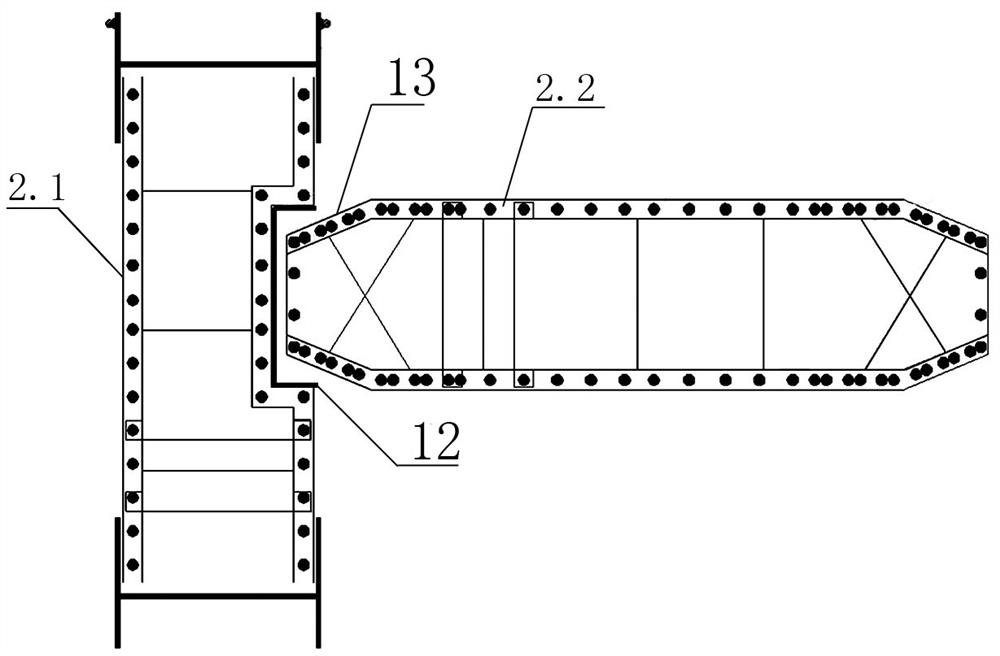

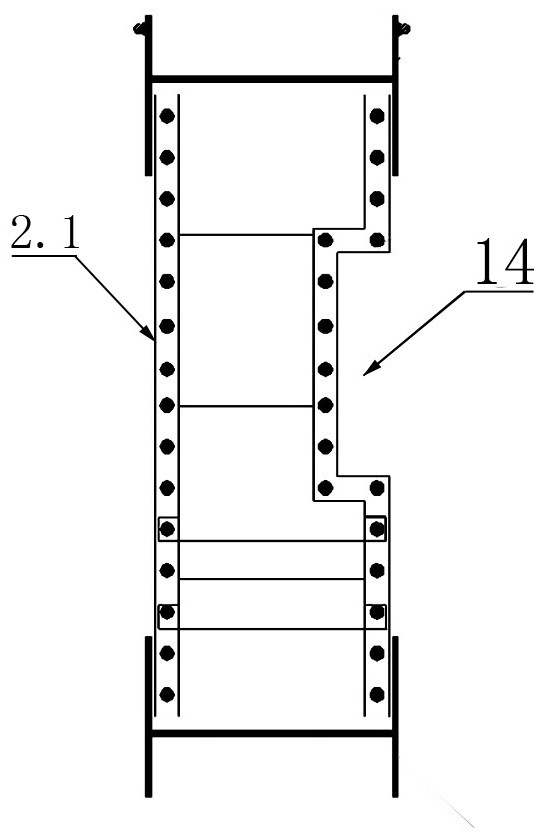

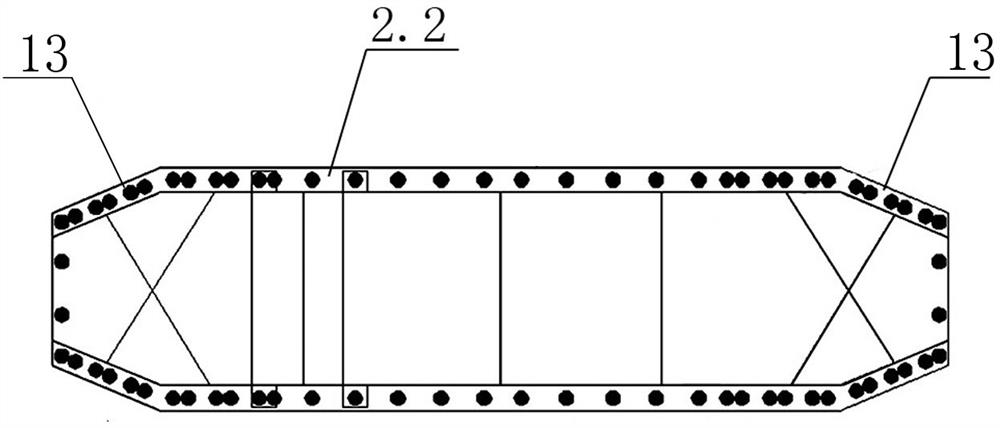

[0044] The construction method of the underground diaphragm wall in the tunnel includes the following steps.

[0045] Step 1: Construction of the guide wall; the construction process of the guide wall in the tunnel is: installation of the upper support of the tunnel → measuring and setting out → breaking the initial support structure at the bottom of the tunnel → digging trenches → binding the steel bars of the guide wall → setting up the formwork → pouring the concrete of the guide wall →Remove the formwork and install cross braces; during the construction of the guide wall in the tunnel, manual excavation is used to construct the guide wall due to the limited underground working space. The stability will be affected to a certain extent. I22a I-beam or Φ36 lead screw is used to support the upper part of the tunnel.

[0046] Step 2: Grooving: A small hydraulic grooving machine is used for grooving. A drill bit is installed in the center of the mechanical grab to increase the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com