A near-shore reflective wave energy-concentrating power generation device

A power generation device and reflective technology, which is applied in the direction of ocean energy power generation, hydropower generation, engine components, etc., can solve the problems of energy conversion efficiency reduction, heave motion amplitude reduction, etc., to improve conversion efficiency, increase oscillation amplitude, The effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

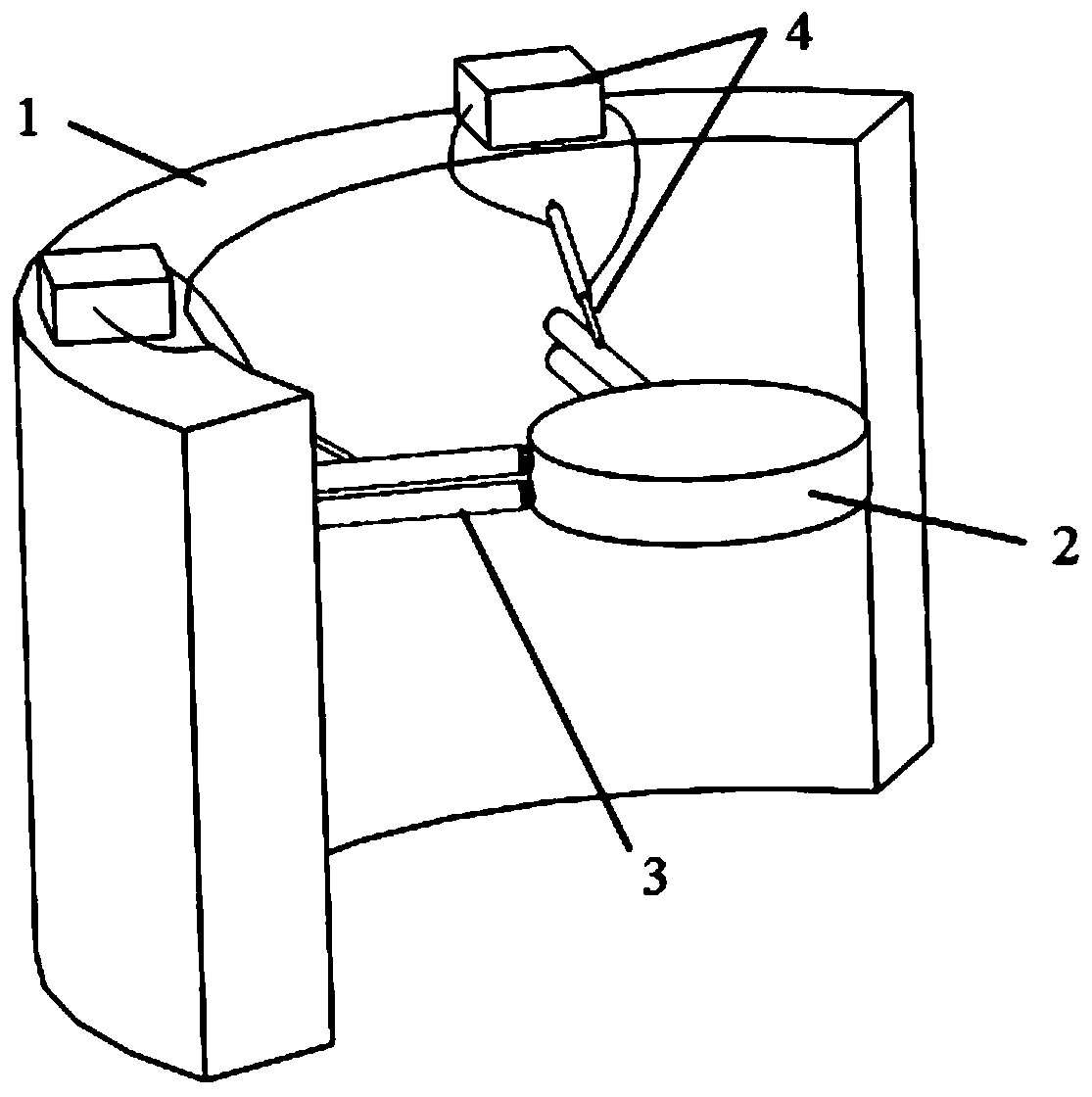

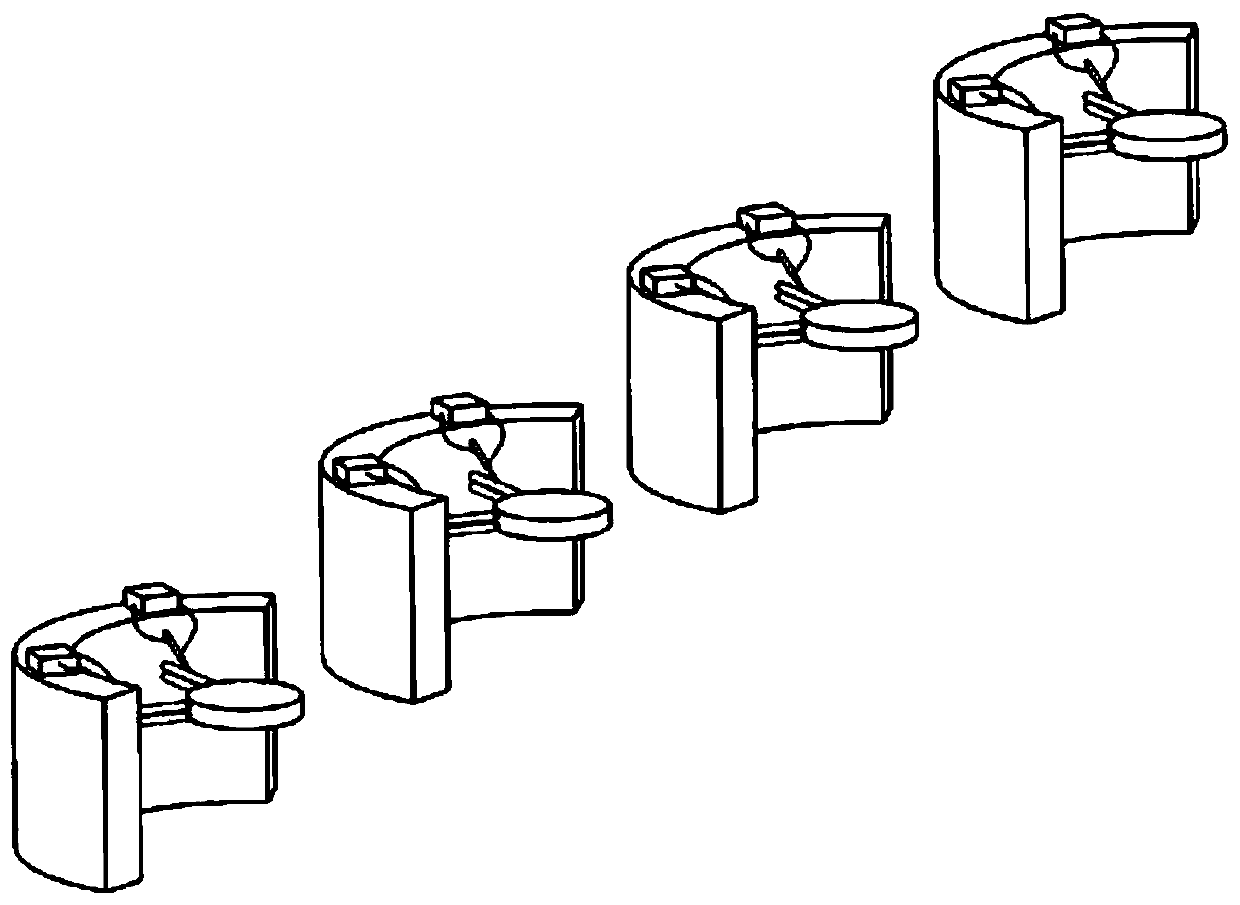

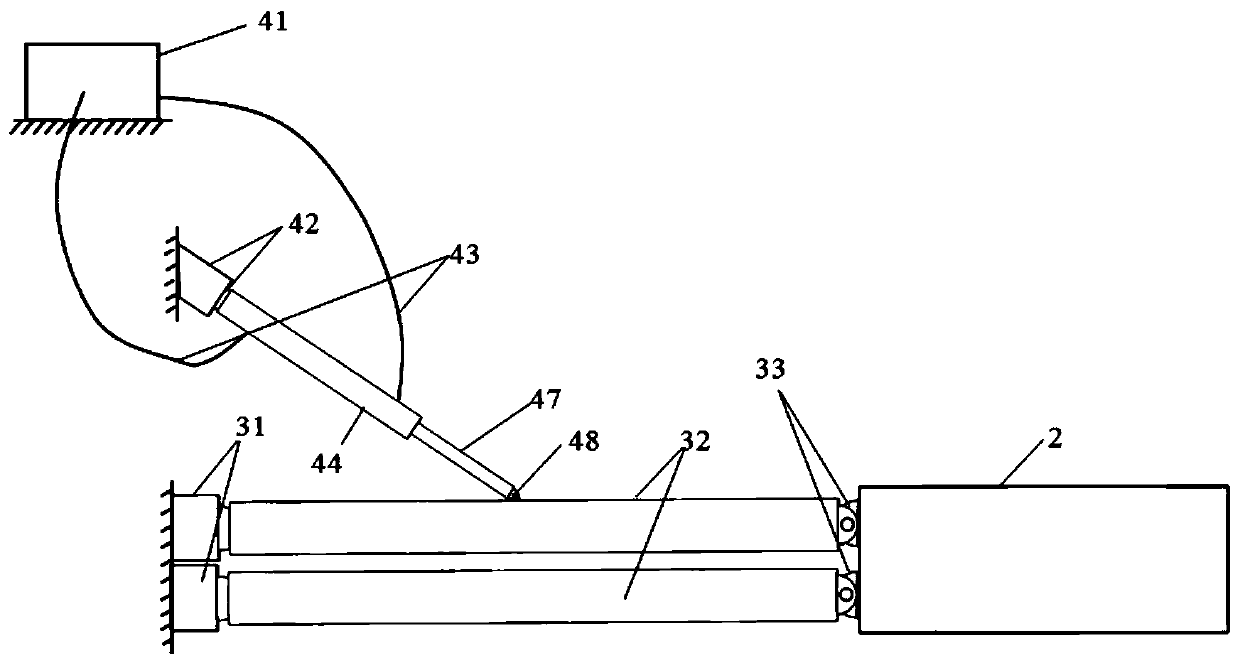

[0036] Example: Combine Figure 1-Figure 8 , a near-shore reflective wave energy-concentrating power generation device of this embodiment is further elaborated:

[0037] A near-shore reflective wave energy-concentrating power generation device, see figure 1 , the device includes an energy-gathering arc wall 1, a rigid arm link 3, a float 2, and a hydraulic power generation system 4; the energy-gathering arc wall 1 is used to gather waves, and the float 2 moves up and down with the waves to capture waves Potential energy, the rigid arm link 3 movably connects the float 2 and the energy-gathering arc wall 1 . There are two sets of rigid arm connecting rods 3 and two sets of hydraulic power generation systems 4 in the power generation device. The symmetrical distribution of the two sets of connecting rod systems 3 can ensure that the position of the float 2 is always at the place where the energy is concentrated. The hydraulic power generation system 4 converts the potential o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com