Multi-bushing lap-joint gas bearing with pre-tightening elastic foils and tilting bottom layer

An elastic foil and gas bearing technology, applied in the field of multi-tile lap belt preloaded elastic foil gas bearings, can solve the problems of increased wear, shortened bearing life, and reduced system stability, and achieve stable performance and avoid pads. Damaged, holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

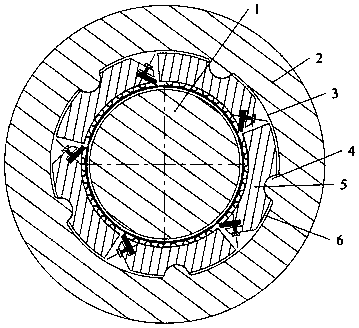

[0032] Such as figure 1 , figure 2 As shown, the present invention provides a multi-tile lap belt pre-tensioned elastic foil gas bearing with bottom tilting, including a shaft 1, a bearing seat 2 and a tilting pad 5, wherein the shaft 1 is embedded in the bearing seat 2 Inside, there are multiple tilting pads 5 arranged between the bearing seat 2 and the shaft 1 along the circumferential direction.

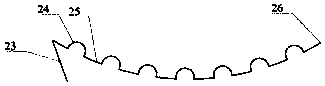

[0033] Among them, such as image 3 As shown, several spherical cap fulcrums 4 are arranged on the inner curved surface 3 of the bearing seat 2 along its circumferential direction, and the spherical cap fulcrums 4 are opened towards the central axis of the bearing seat 2, as shown in image 3 as shown in b.

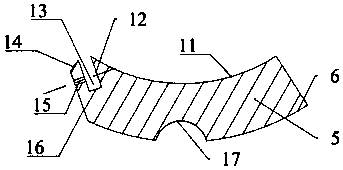

[0034] Such as Figure 4 As shown, the tilting pad 5 is a fan-shaped structure, wherein, the outer curved surface 6 of the tilting pad 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com