Super-resolution digital holographic imaging system and imaging method

A digital holography and super-resolution technology, applied in instruments and other directions, can solve the problem that the lateral resolution of digital holography needs to be improved, and achieve the effect of strong scalability and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

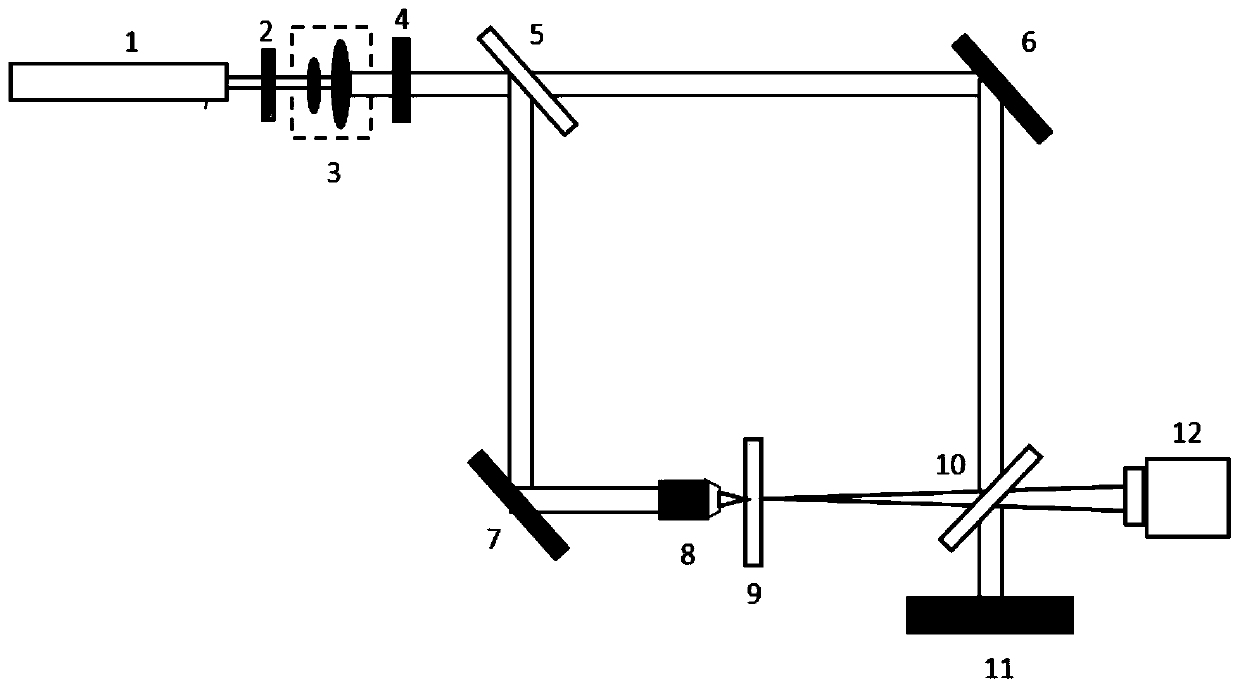

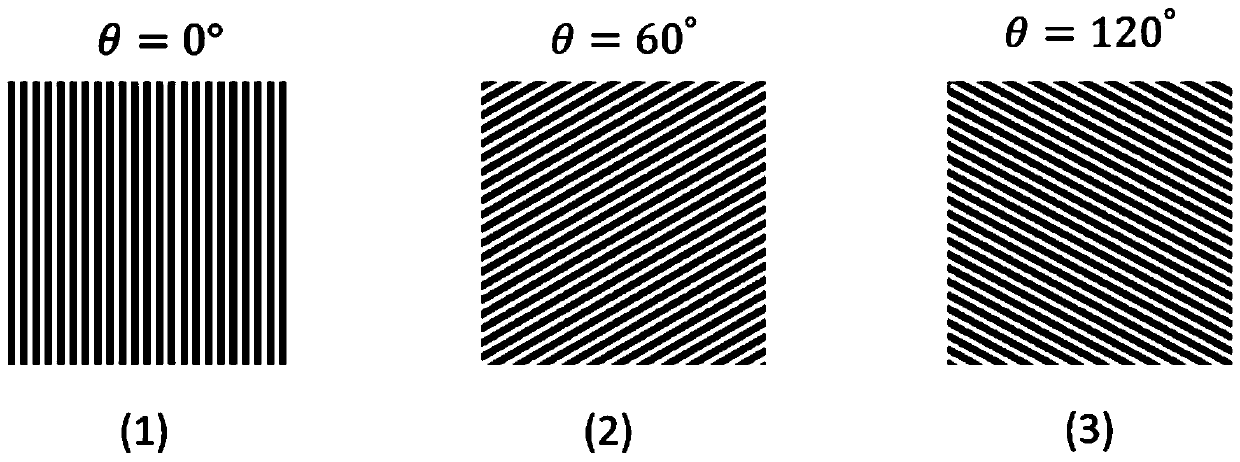

[0025] Such as figure 1 as shown, figure 1 It is a schematic diagram of a super-resolution digital holographic imaging system; as shown in the figure, this imaging system includes: the attenuation sheet 2 is placed sequentially on the coaxial direction of the laser 1, the beam expander 3 generates a larger beam, and then passes through the transmission type SLM 4 generates structured light, which is then divided into two beams of light waves with the same energy by the first beam splitting plate 5; one beam is reflected by the first reflector 6 and then transmitted through the second beam splitting plate 10 to exit in parallel on the surface of the object 11 to be measured , the reflected light from the surface of the object 11 to be measured is reflected by the second spectroscopic flat plate 10, and then enters the image sensor 12 as object light; The focused lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com