Online compensation method for spatial error of multi-axis linkage CNC machine tool

A space error, CNC machine tool technology, applied in the field of error compensation, can solve problems that do not conform to the process business process and quality management system, affect production efficiency, reduce machine tool utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

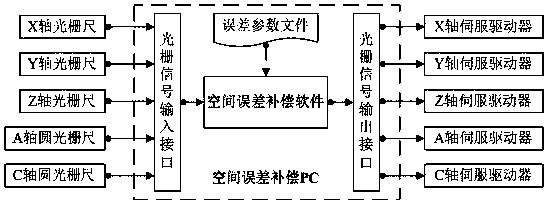

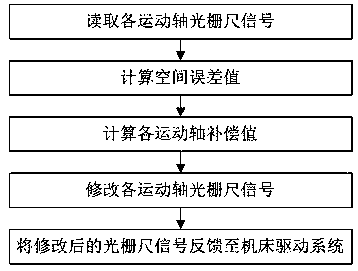

[0081] The present invention is realized through the following technical solutions, as Figure 1-Figure 4 As shown, a multi-axis linkage CNC machine tool space error online compensation method, the multi-axis linkage CNC machine tool is an AC swing head five-axis CNC machine tool, and the AC swing head five-axis CNC machine tool compensates the PC machine and the servo driver through the space error Connect; the spatial error compensation PC includes a grating signal input interface, spatial error compensation software, and a grating signal output interface; the spatial error compensation software collects the grating signal of the AC swing head five-axis CNC machine tool through the grating signal input interface, according to the grating The position coordinates of the signal feedback and the error value in the error parameter file in the space error compensation software calculate the space error of the current position and the compensation value of each axis of the AC swing...

Embodiment 2

[0087] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the AC swing head five-axis CNC machine tool includes five motion axes, which are X-axis, Y-axis, Z-axis, A-axis, and C-axis; wherein the X-axis includes the X-axis linear grating ruler, and the Y-axis includes the Y-axis Linear grating scale, Z-axis includes Z-axis linear grating scale, A-axis includes A-axis circular grating scale, C-axis includes C-axis circular grating scale; the X-axis linear grating scale, Y-axis linear grating scale, Z-axis linear grating scale The ruler, the A-axis circular grating ruler, and the C-axis circular grating ruler are respectively connected to the grating signal input interface.

[0088] The servo driver includes an X-axis servo driver, a Y-axis servo driver, a Z-axis servo driver, an A-axis servo driver, and a C-axis servo driver respectively connected to the grating signal output interface.

[0089] It should be noted that, throu...

Embodiment 3

[0092] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the error parameter file in the spatial error compensation software is a text file in which error parameters are obtained through measurement according to certain rules.

[0093] It should be noted that, through the above improvements, the error parameter file inserted into the spatial error compensation software is a text file with error parameter values written according to certain rules. The error parameter values are obtained through measurement and are the input of the error model. The Spatial Error Compensation software uses the error parameter values to calculate the spatial error. The error parameter value is related to the structure type of the machine tool. This embodiment takes the AC swing head axis numerical control machine tool as an example, including the following error parameters:

[0094] A total of 18 items of motion errors of X / Y / Z linear axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com