X-ray flat panel detector and preparation method thereof

A flat-panel detector and X-ray technology, applied in the field of X-ray detectors, can solve the problems of reducing the spatial resolution of the detector and image blurring, and achieve the effects of improving reliability, prolonging life, and improving package sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

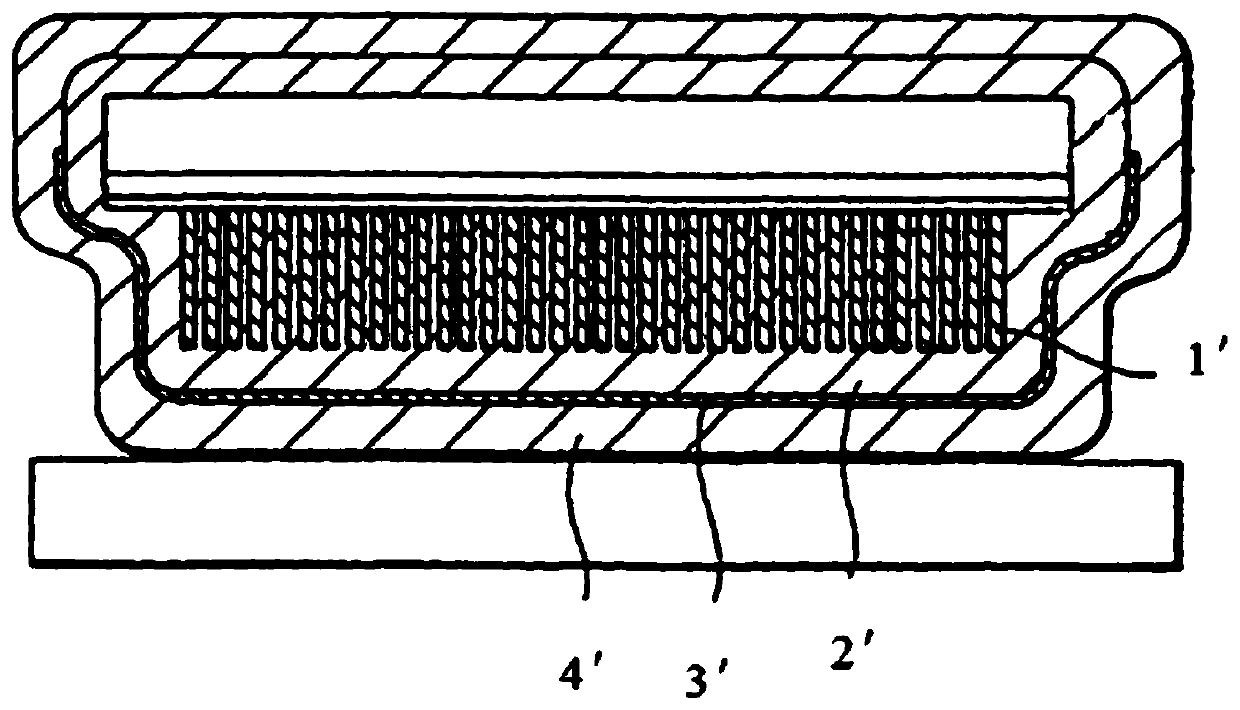

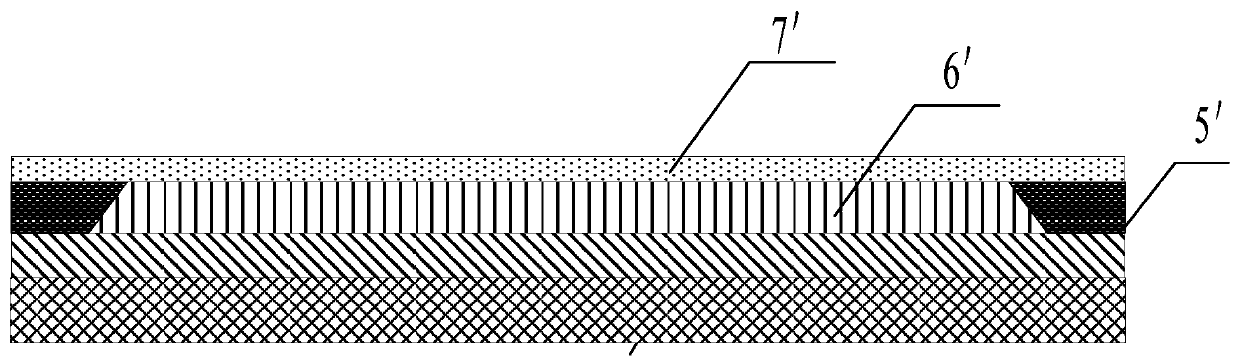

[0058] Such as Figure 3-12 As shown, this embodiment provides an X-ray flat panel detector using a Frit-packaged scintillator and a preparation method thereof.

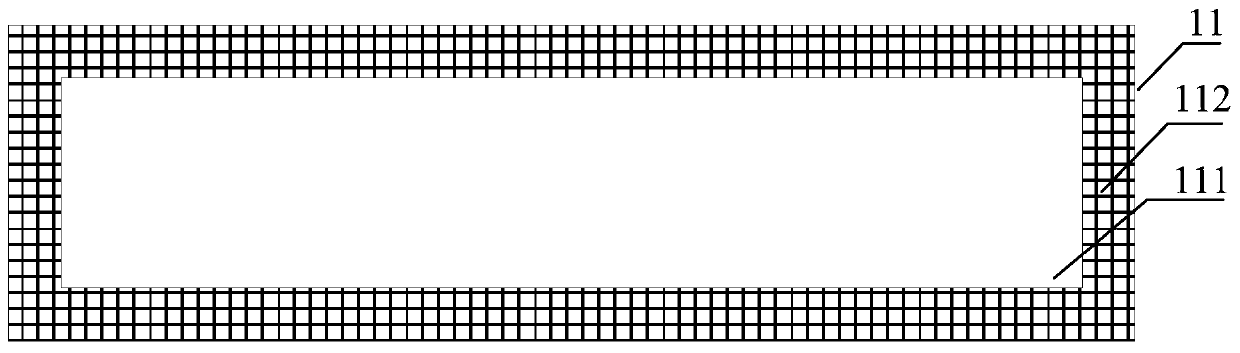

[0059] Such as Figure 9As shown, the present invention provides an X-ray flat panel detector. The X-ray flat panel detector includes a substrate 11 , a reflection layer 12 , a Frit packaging layer 13 , a scintillator layer 14 , an adhesive layer 15 , and a visible light sensor 16 . Specifically, the substrate is provided with a non-encapsulation area 111 and an encapsulation area 112 surrounding the non-encapsulation area, the reflective layer 12 is deposited on the substrate 11, and the Frit encapsulation layer 13 is formed on the reflective layer corresponding to the substrate encapsulation area 112 12; the scintillator layer 13 is formed on the reflective layer 12 corresponding to the non-encapsulation area 111 of the substrate; the adhesive layer 15 covers the surface of the visible light sensor 16 correspondi...

Embodiment 2

[0087] The technical solution of this embodiment is basically the same as that of Embodiment 1, except that this embodiment also includes a step of coating the Frit encapsulation layer multiple times—pre-sintering.

[0088] Specifically, after the Frit encapsulation layer is coated, pre-sintering is performed, and after cooling to room temperature, the Frit encapsulation layer is coated and then pre-sintered. As above, the step of coating the Frit encapsulation layer—pre-sintering is repeated one or more times to obtain Frit encapsulation layers with different thicknesses. This method is also conducive to the smooth discharge of gas generated by the decomposition of organic matter in the Frit encapsulation layer.

[0089] Through this embodiment, the packaging and airtightness of the X-ray flat panel detector can be improved, the reliability in a high-temperature and high-humidity environment can be improved, and the service life can be prolonged.

[0090] To sum up, the X-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com