Sealing arrangement for a motor vehicle window, composite seal, and method for producing composite seal

A sealing device and composite sealing technology, which is applied to sealing devices, engine seals, vehicle parts, etc., can solve problems such as deflection, and achieve the effect of improving noise performance and surface appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

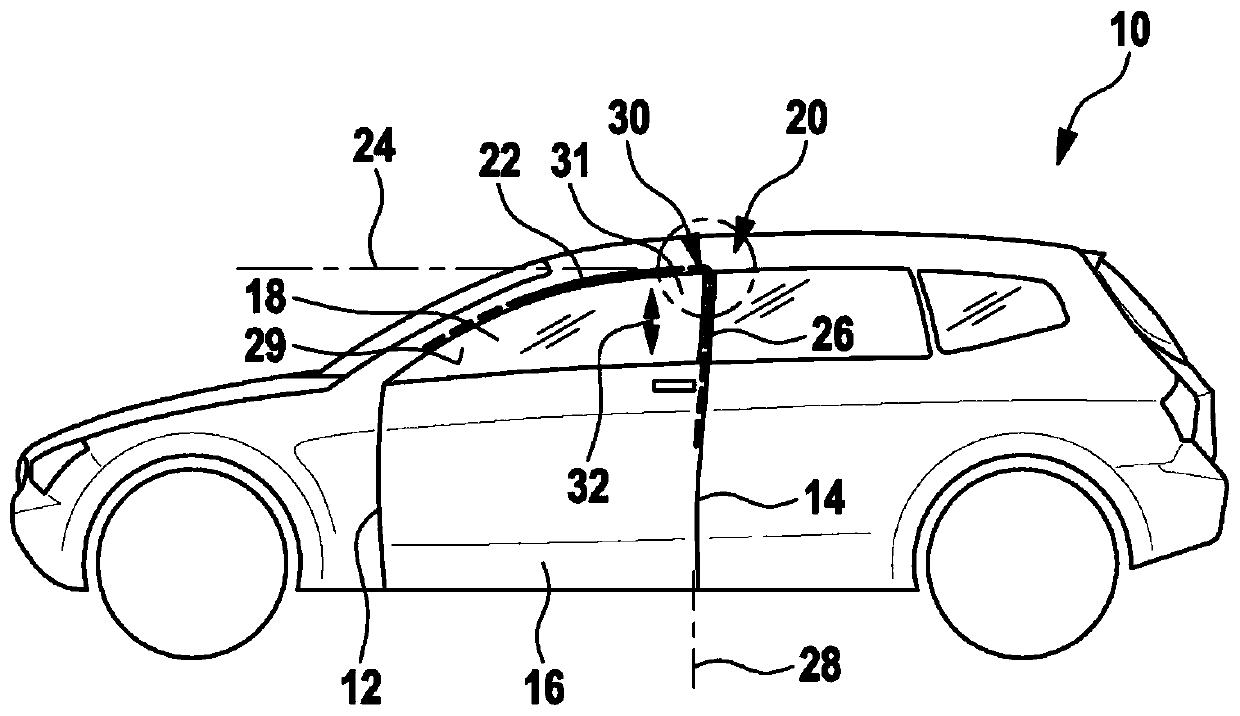

[0041] figure 1 A motor vehicle roughly indicated by 10 is schematically shown.

[0042] The motor vehicle 10 has an A pillar 12 and a B pillar 14. A front door 16 having a movable front door window 18 is pivotally installed between the A pillar 12 and the B pillar 14.

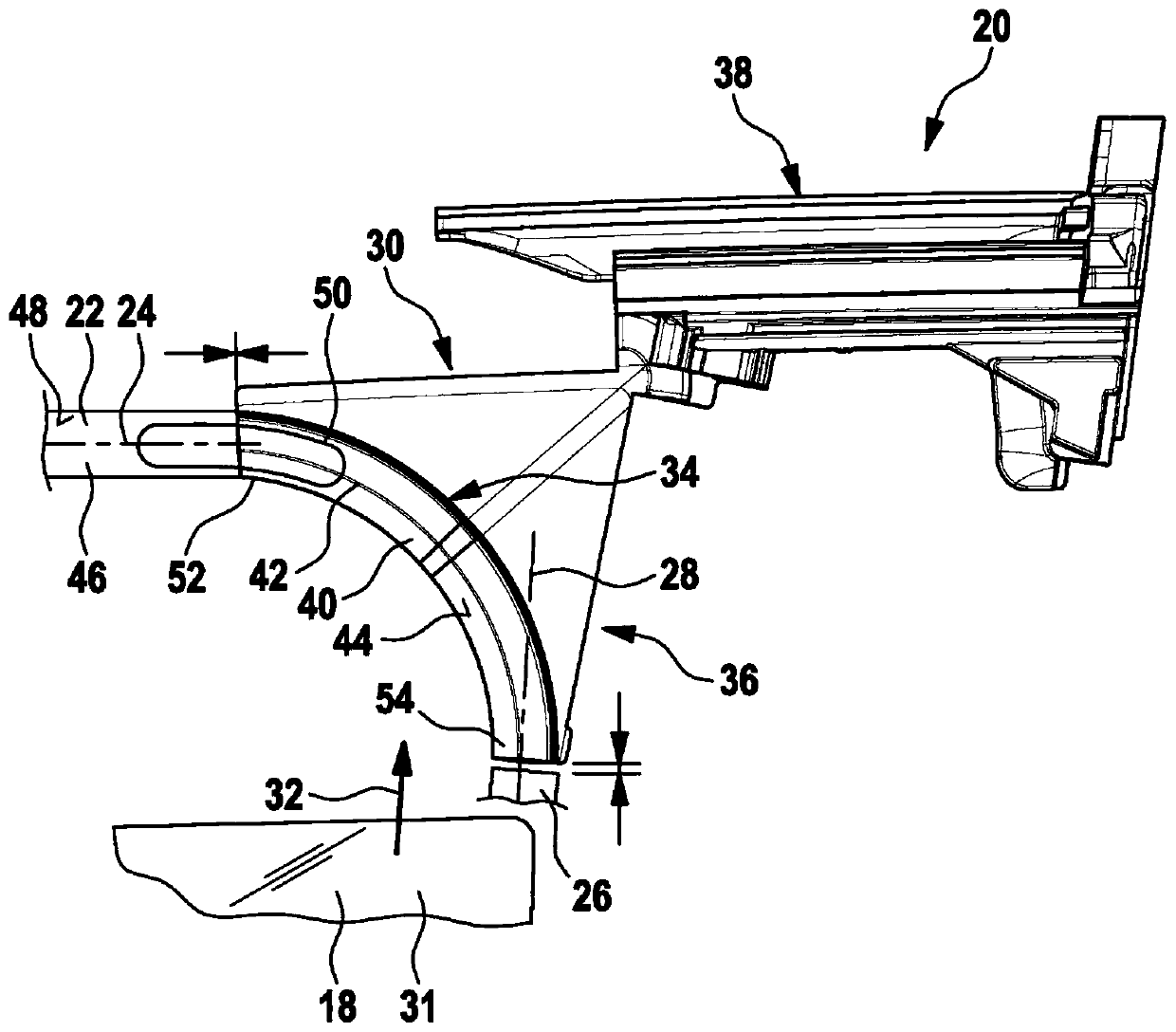

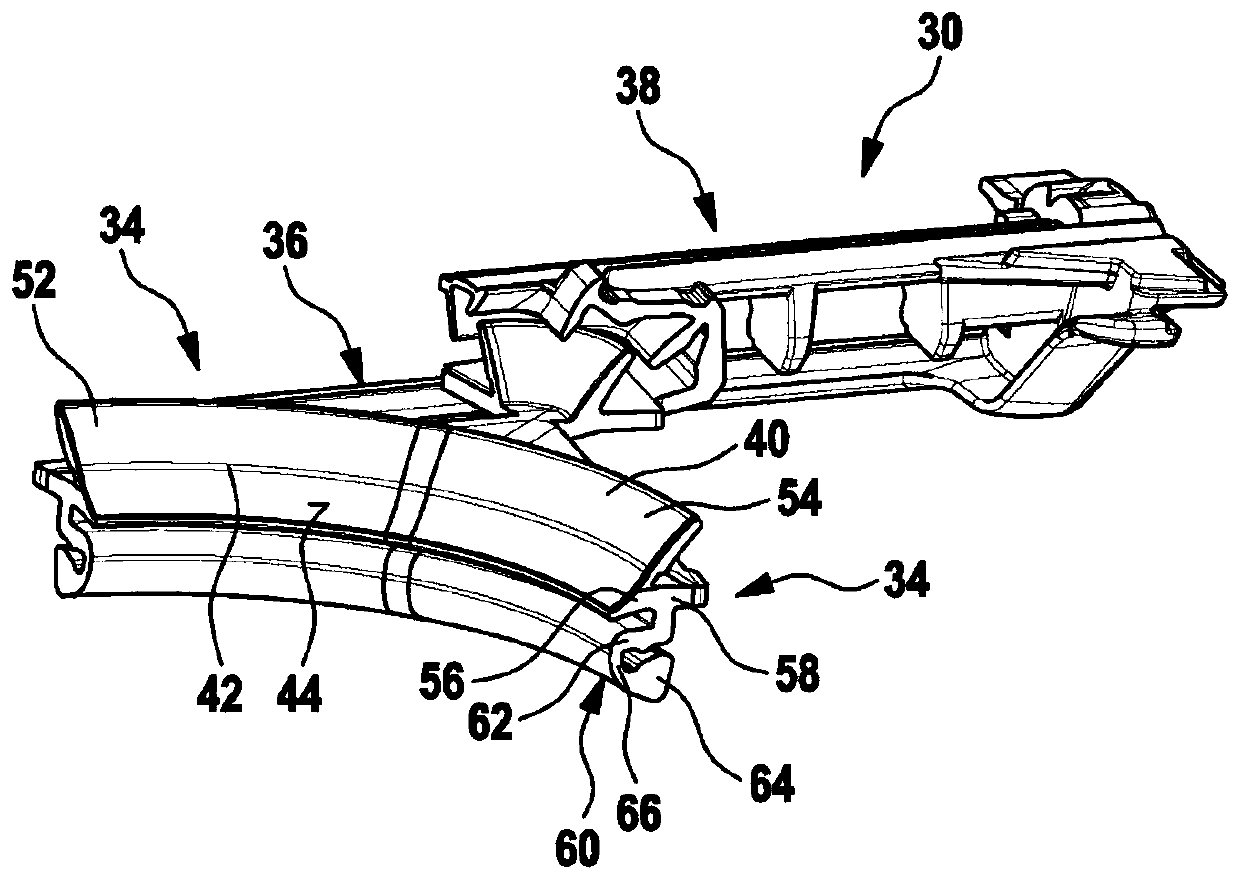

[0043] The composite seal 20 is provided for sealing the front door window 18 relative to the front door 16. The composite seal 20 includes a first extruded seal 22 that is arranged and oriented substantially horizontally along the first sealing axis 24. The first extruded seal 22 is used to seal the upper side edge of the front door window 18. In addition, the composite seal 20 includes a second extruded seal 26 that is arranged and oriented generally vertically along the second sealing axis 28. The second sealing axis 28 is oriented at an angle greater than 45°, in particular greater than 60°, in particular greater than 70° with respect to the first sealing axis 24. The second extruded seal 26 is generally us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com