Illumination source for an inspection apparatus, inspection apparatus and inspection method

A technology for inspection equipment and irradiation sources, applied in X-ray equipment, optomechanical equipment, microlithography exposure equipment, etc., and can solve problems such as difficulty in achieving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

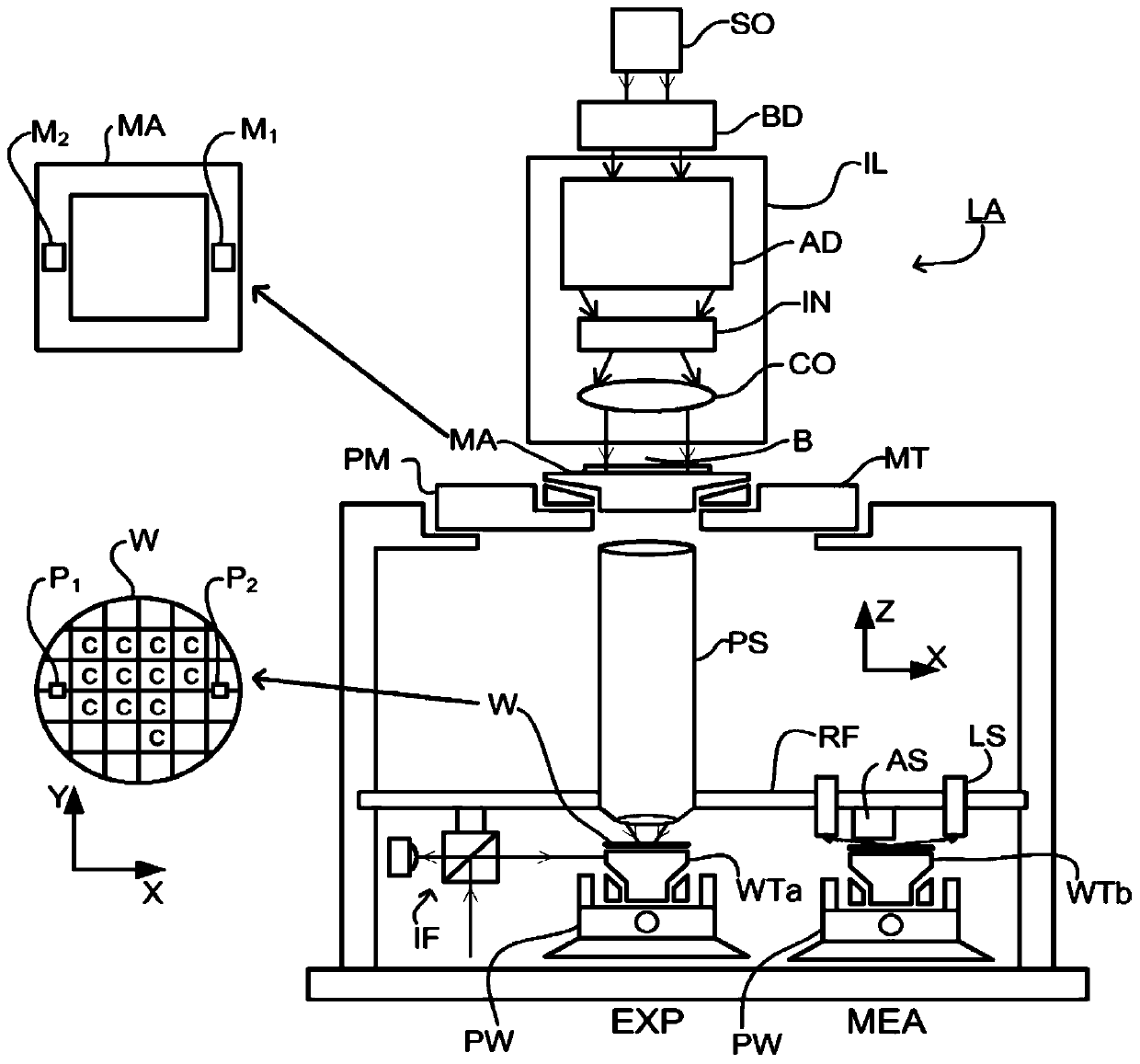

[0025] Before describing embodiments of the invention in detail, it is instructive to demonstrate an exemplary environment in which embodiments of the invention may be implemented.

[0026] figure 1 A lithographic apparatus LA is schematically depicted. The apparatus comprises an illumination system (illuminator) IL configured to condition a radiation beam B (e.g. UV radiation or DUV or EUV radiation), configured to support a patterning device (e.g. a mask) MA and connected to a Parameters A patterning device mount or support structure (e.g., a mask stage) MT of a first positioner PM for precisely positioning the patterning device; each configured to hold a substrate (e.g., a resist-coated wafer) W and two substrate handling stages (e.g., wafer handling stages) WTa and WTb each connected to a second positioner PW configured for precisely positioning the substrate according to certain parameters; MA imparts a pattern of radiation beam B projected onto a projection system (eg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com