Inspecting device, inspecting unit, and inspecting method

一种检查装置、检查方法的技术,应用在测量装置、仪器、测试复合材料等方向,能够解决漏测、缺陷、漏查等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, first, the structure of the composite material part inspected in this embodiment and problems that may arise in the ultrasonic inspection of the composite material part will be described.

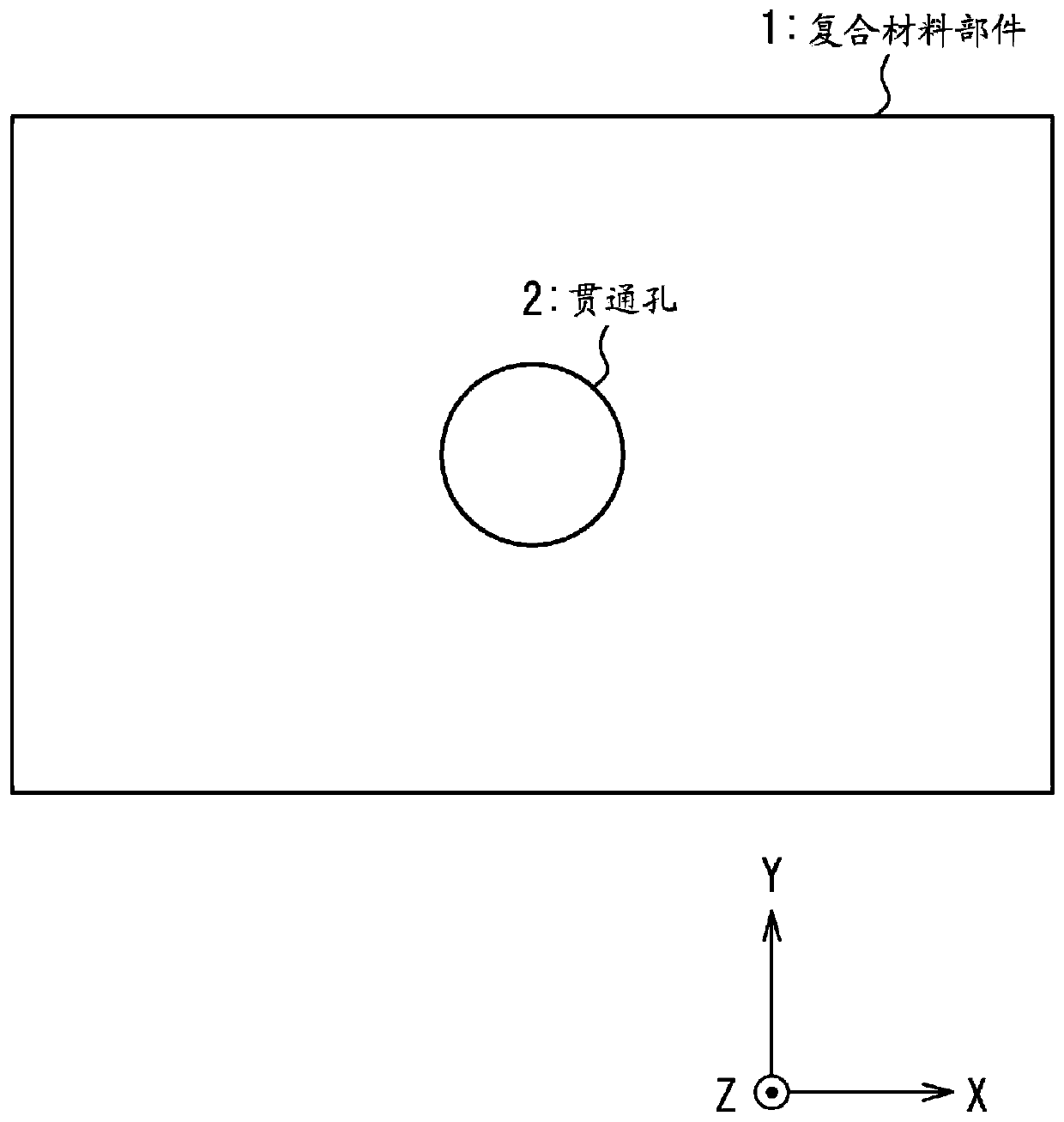

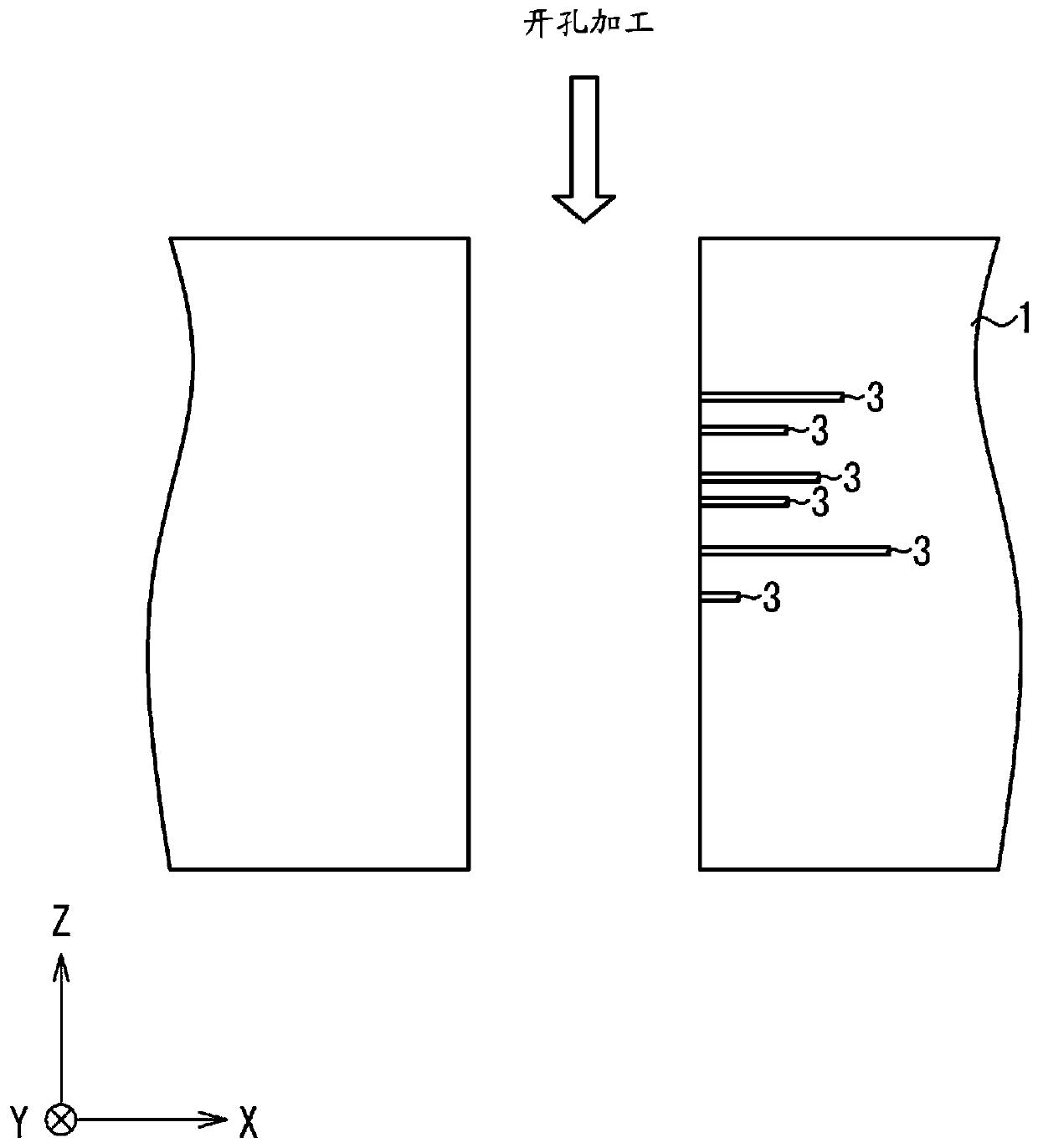

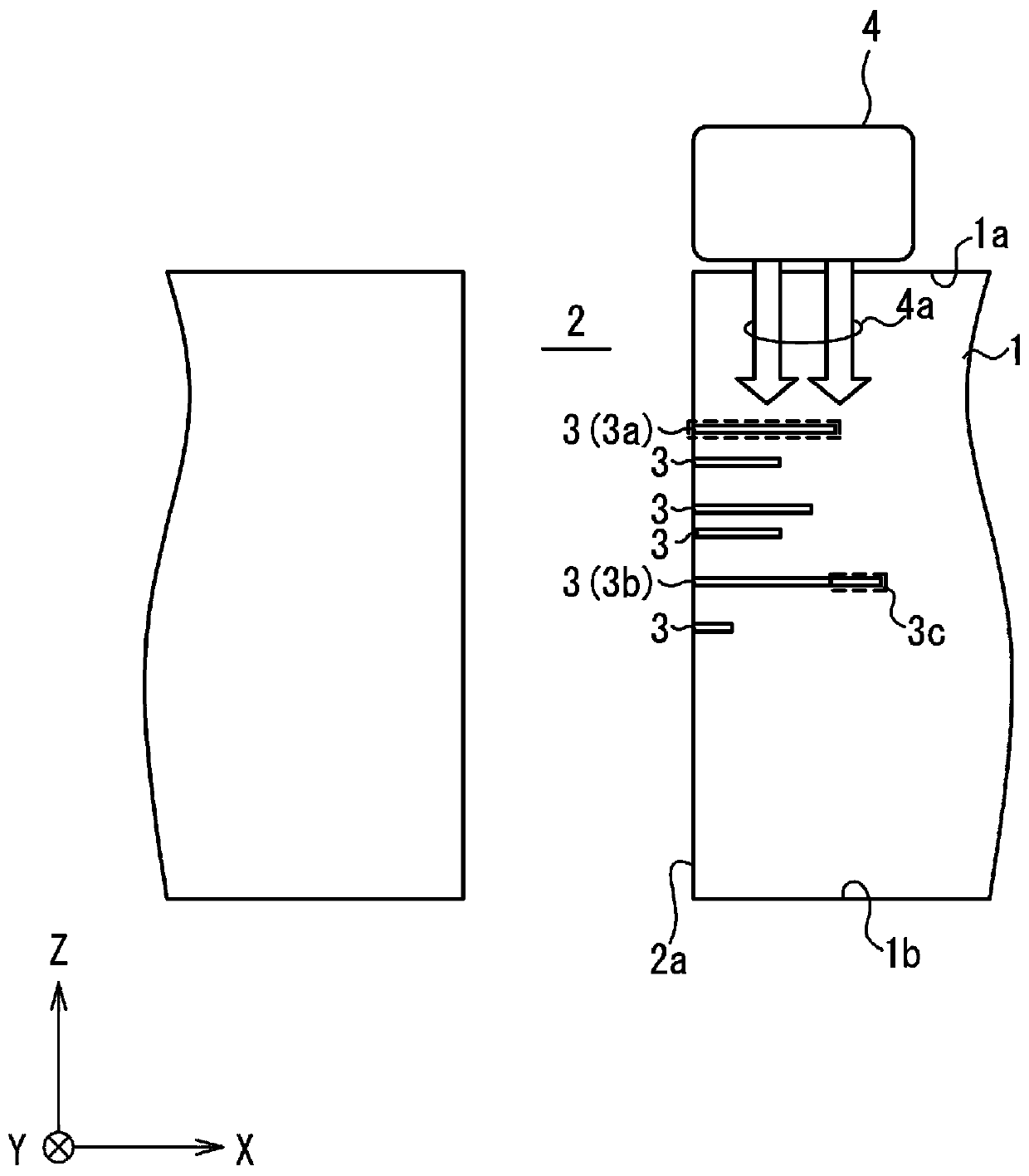

[0038] figure 1 It is a top view of an example of the structure of the composite material part 1 inspected in this embodiment, figure 2 is partially expressed figure 1 An enlarged cross-sectional view of the structure of the composite component 1 shown. In the following description, an XYZ orthogonal coordinate system is introduced. In the XYZ rectangular coordinate system, the Z-axis direction is defined along the thickness direction of the composite material member 1 , and the X-axis direction and the Y-axis direction are defined to be perpendicular to each other in the in-plane direction of the composite material member 1 .

[0039] The composite material part 1 is formed of a composite material (for example, CFRP) combining resin and fibers. In the present embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com