System and method for mask defect detection

A mask and defect technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., can solve the problems of complex mask layout design and inability to detect mask pattern defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

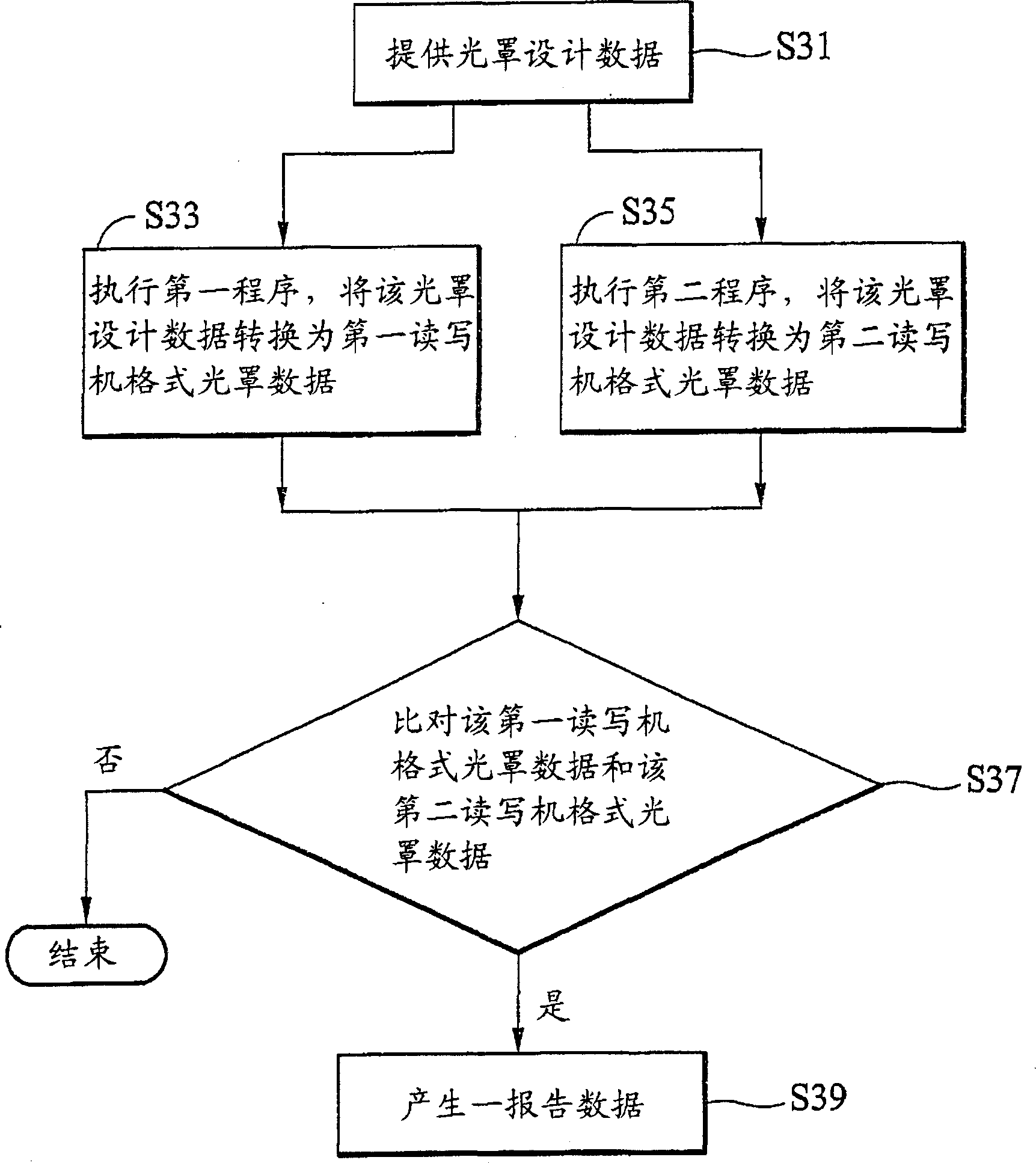

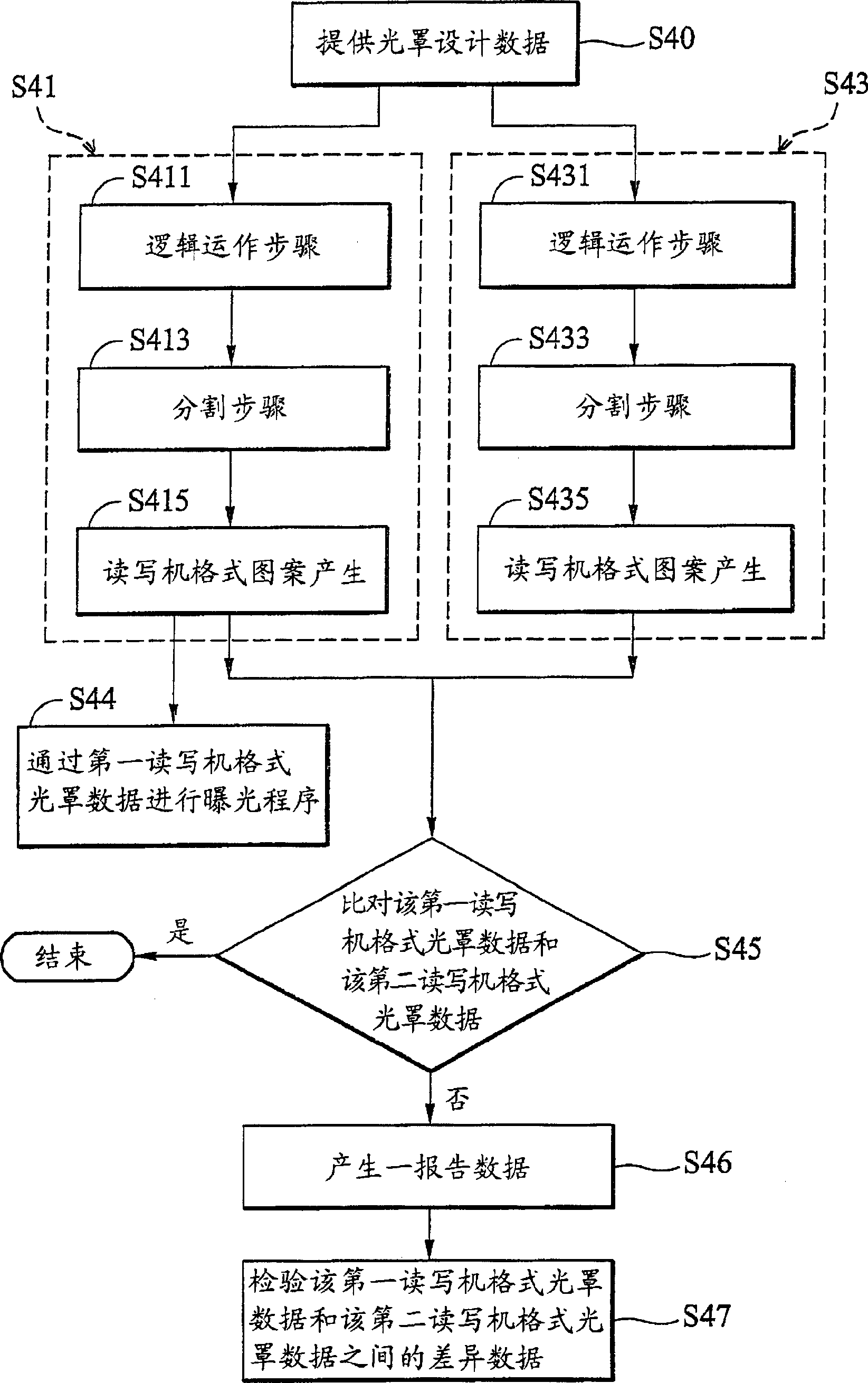

[0023] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the preferred embodiments are specially cited below, together with the attached drawings Figure 1 to Figure 4 , give a detailed explanation. The description of the present invention provides different examples to illustrate the technical features of different implementations of the present invention. Wherein, the configuration of each element in the embodiment is for illustration, not for limiting the present invention. In addition, part of the symbols in the figures in the embodiments are repeated for the purpose of simplifying the description, and do not imply the relationship between different embodiments.

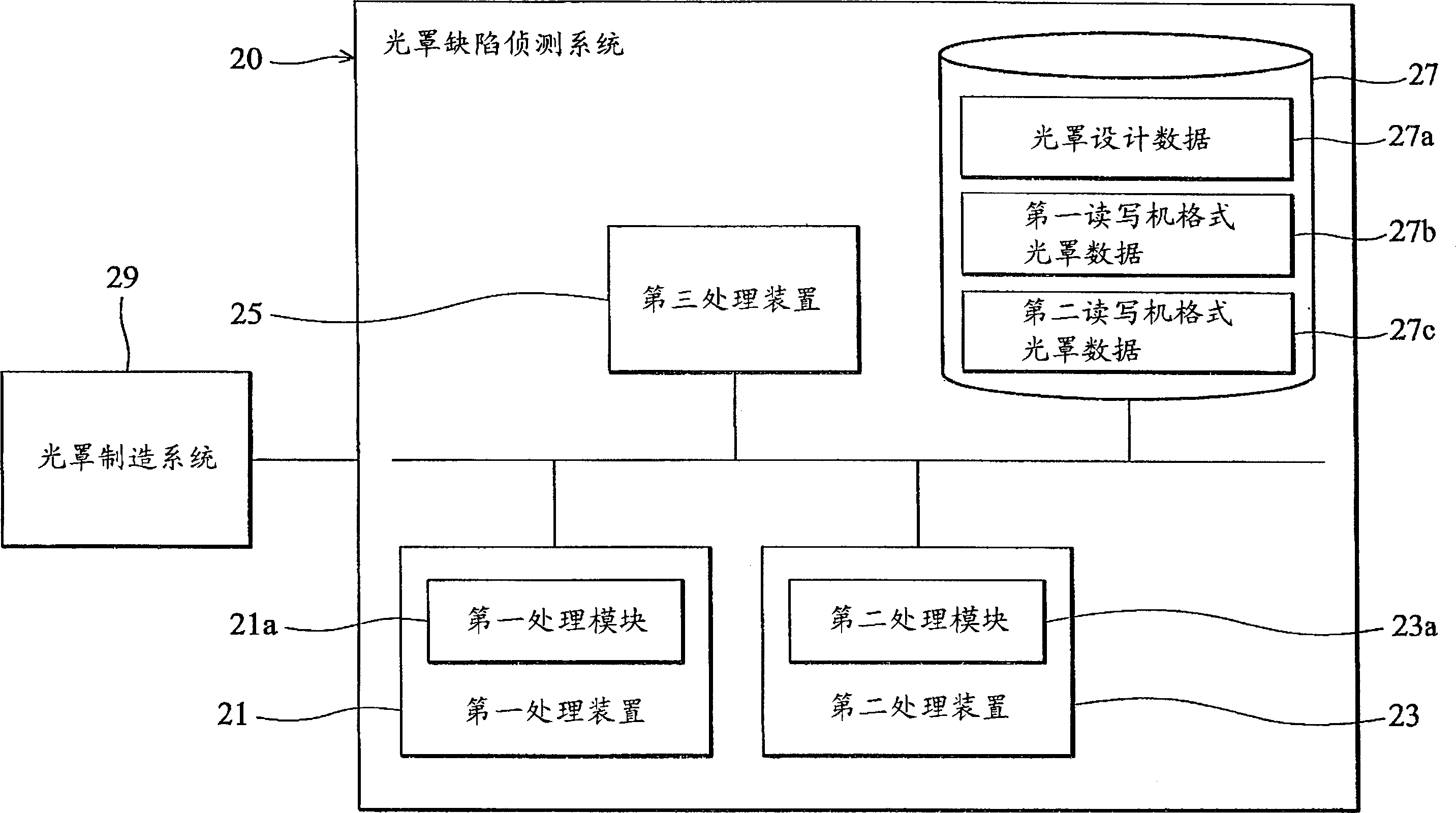

[0024] figure 1 is a schematic diagram showing a mask defect detection system according to an embodiment of the present invention. According to an embodiment of the present invention, the photomask defect detection system 20 is implemented in connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com