Method for detecting defect of semiconductor elements

A detection method and semiconductor technology, which is applied in the direction of semiconductor/solid-state device testing/measurement, can solve problems such as difficulties, long production time, and inability to detect defects or particles, and achieve time-saving and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

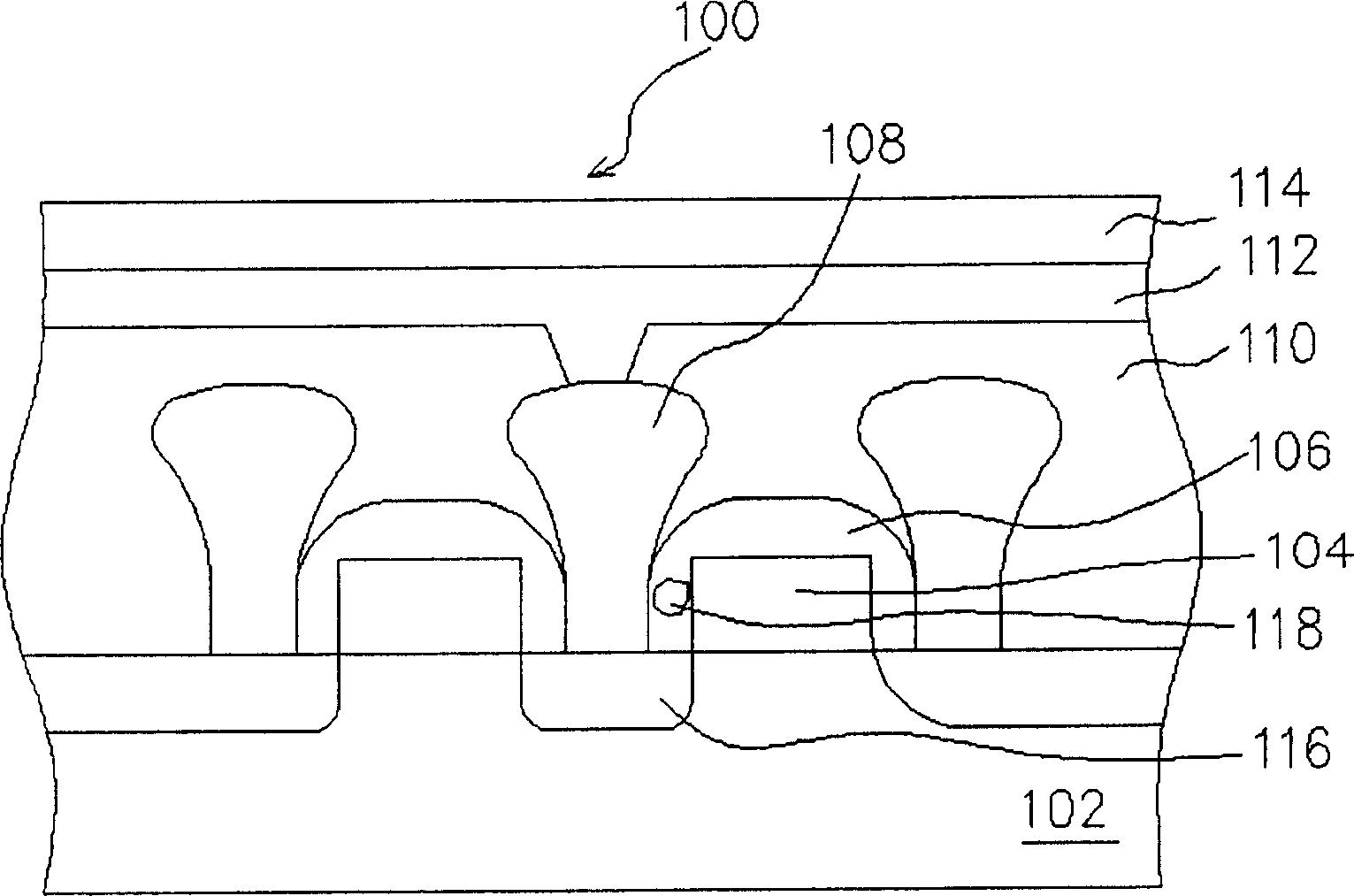

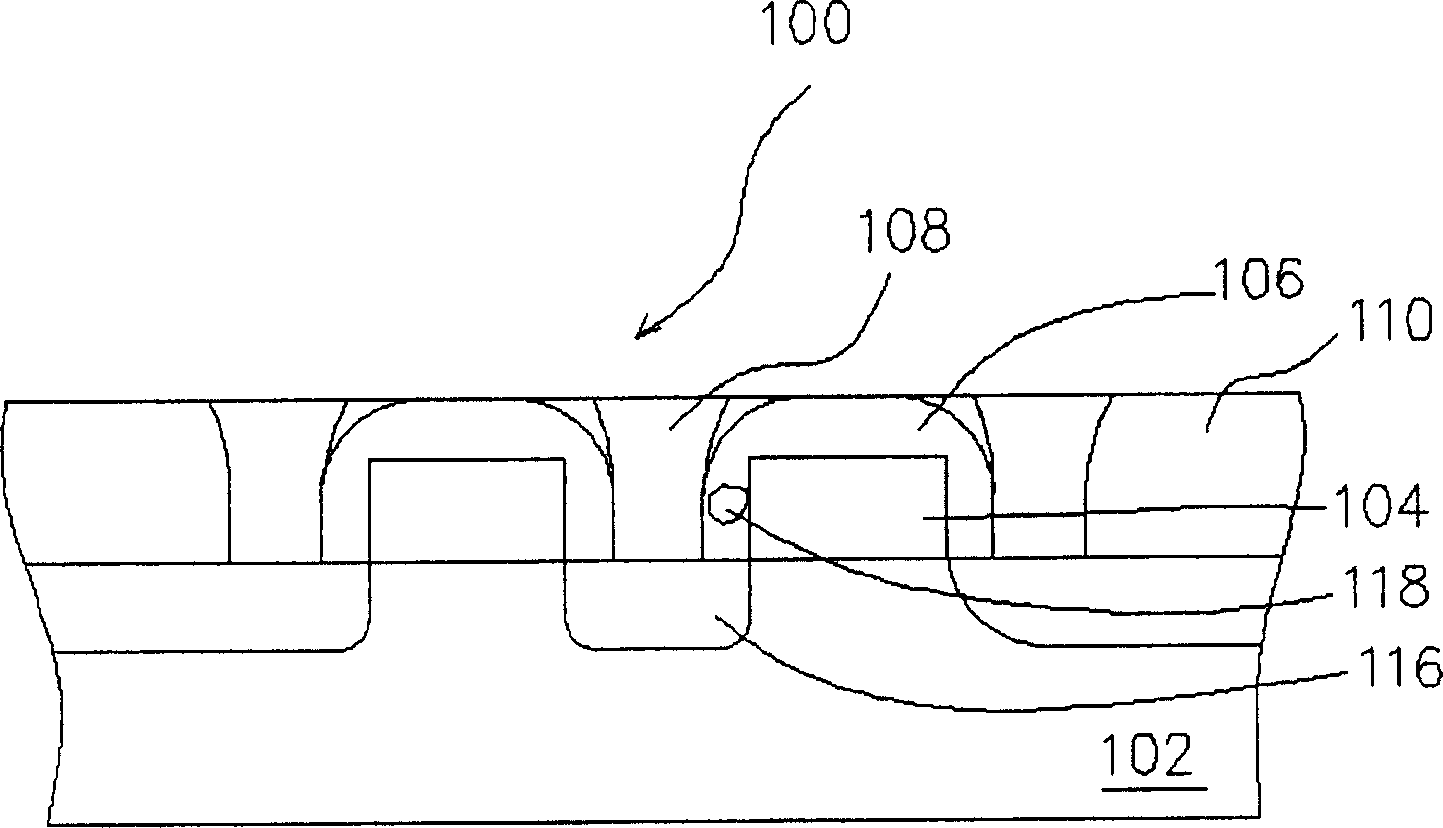

[0037] Provide a semiconductor chip (DRAM) with a line width of 0.15 μm, and perform a grinding step on the semiconductor chip until the plug does not cover the top of the gate. In this grinding step, the grinding time is, for example, about 12 minutes. After the semiconductor chip is cleaned, the insulating layer between the gate and the plug is removed. In this step, for example, a wet etching step is performed first, using hydrofluoric acid (HF) solution as an etchant, and etching is performed for 1 minute. A reactive ion etching process is then performed for 1 minute. A cleaning step is also performed after the insulating layer between the gate and the plug. The semiconductor chip is then inspected using a scanning electron microscope. The result is as Figure 2A and Figure 2B As shown (the part in the figure is the storage unit area of the DRAM).

experiment example 2

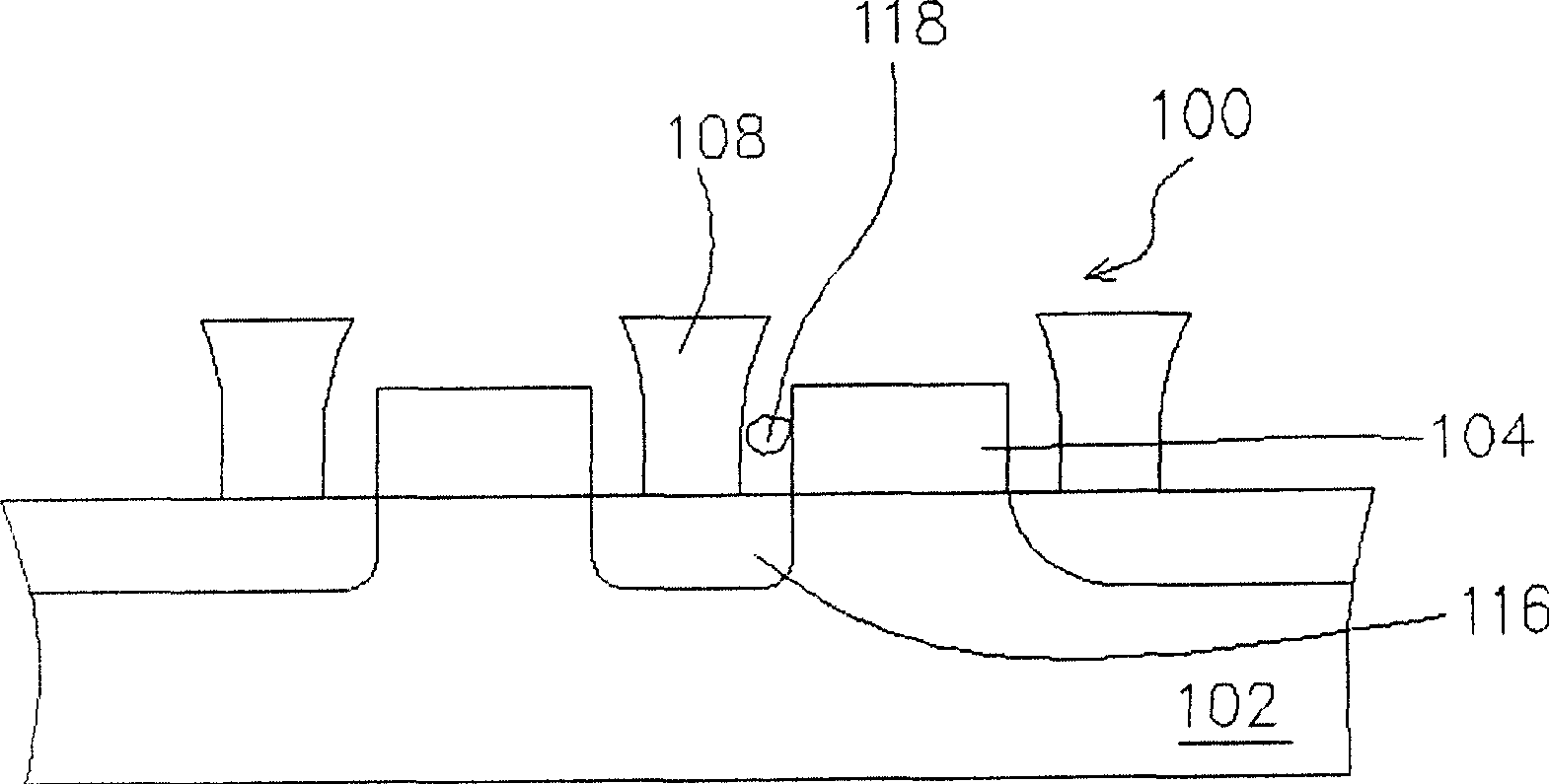

[0039] Provide a semiconductor chip (DRAM) with a line width of 0.13 μm, and then perform the same process steps as in Experimental Example 1 on this semiconductor chip, and then use a scanning electron microscope to detect this semiconductor chip. The result is as Figure 3A and Figure 3B As shown (the part in the figure is the storage unit area of the DRAM).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com