Nondestructive conveying device and working method thereof

A conveying device and conveying line technology, which is applied to conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as affecting production efficiency, adverse warehouse management, damage, etc., so as to reduce the workload of workers and improve work efficiency. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, a lot of specific details are given in order to provide a more thorough understanding of the present invention. However, it is obvious to those skilled in the art that the present invention can be implemented without one or more of these details. In other examples, in order to avoid confusion with the present invention, some technical features known in the art are not described.

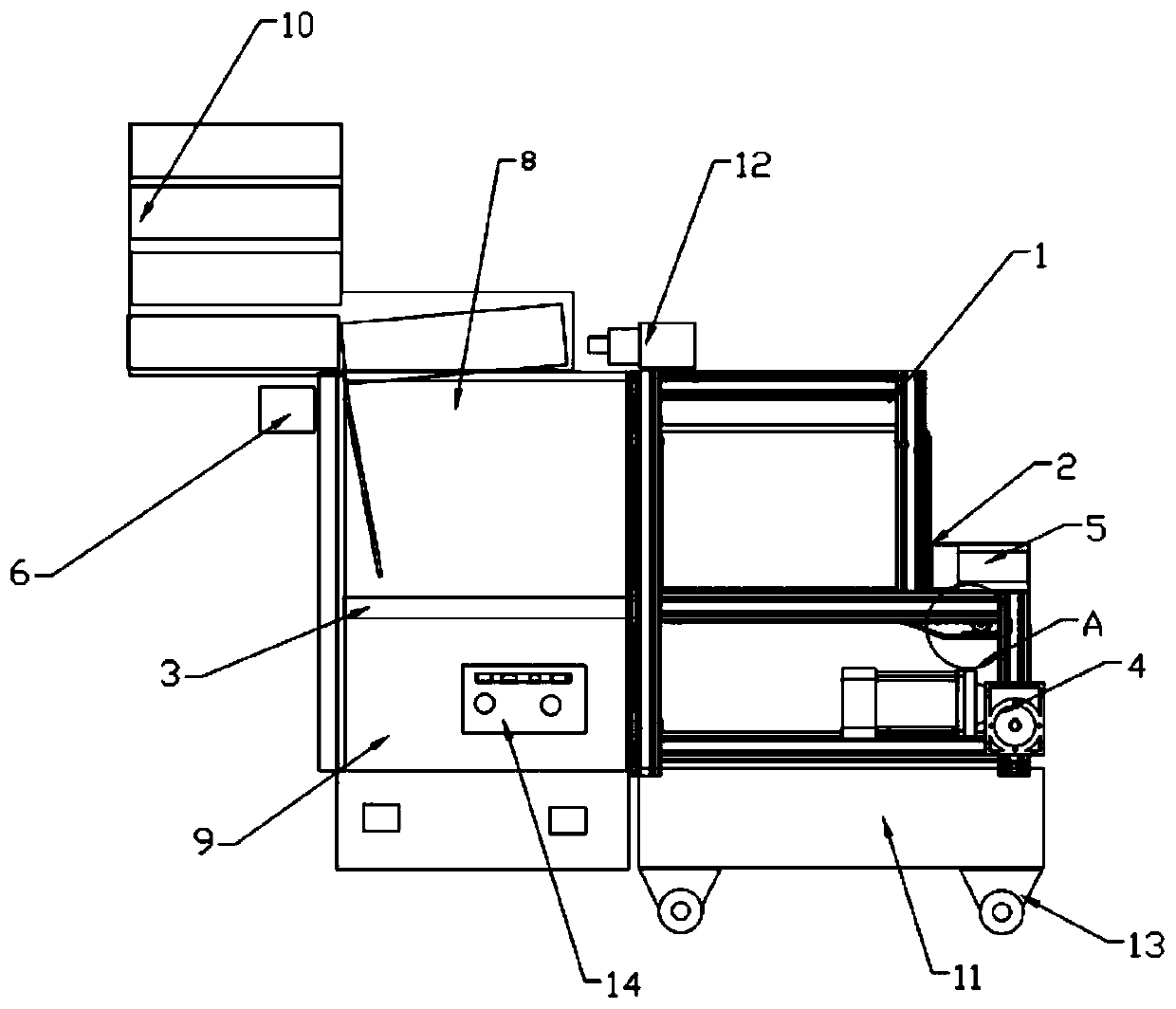

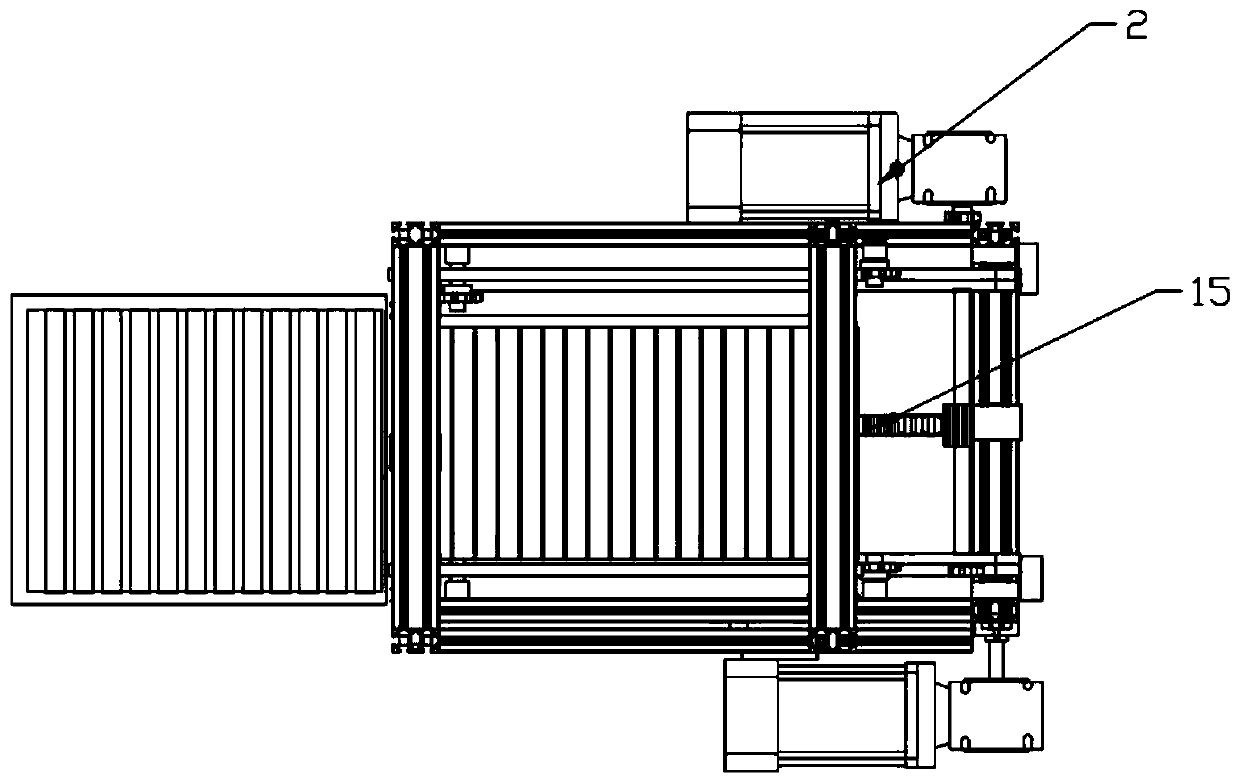

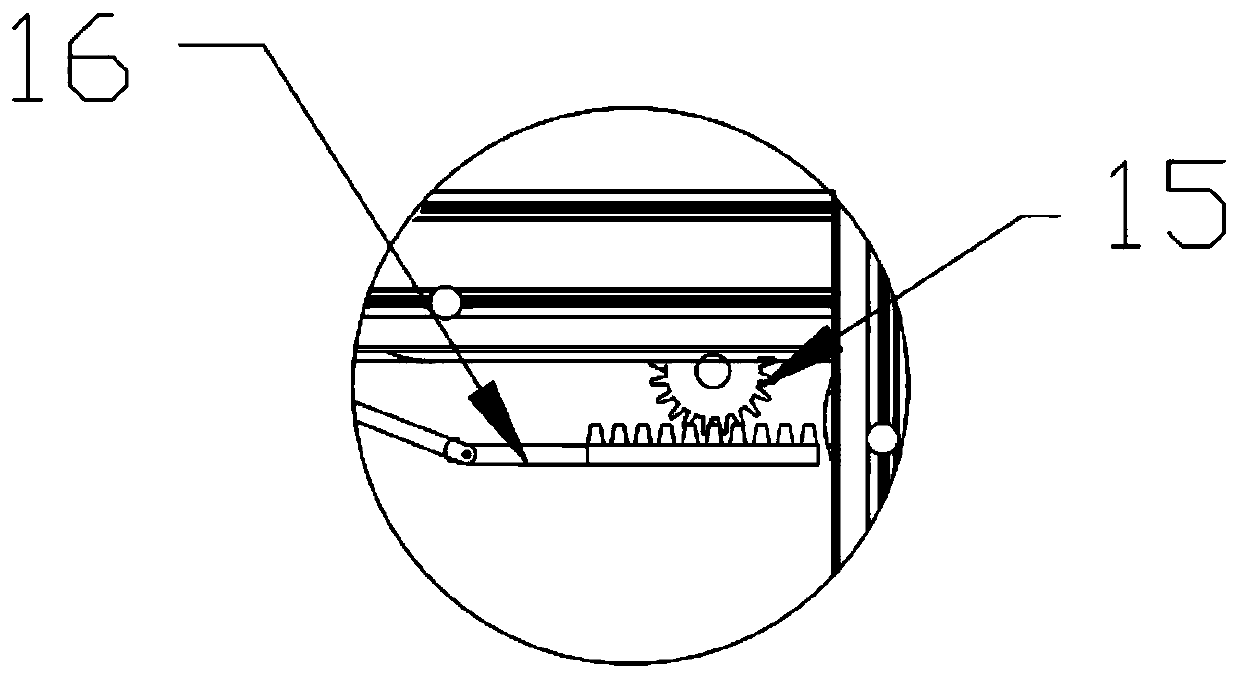

[0032] Such as Figure 1 to Figure 3 A non-destructive and broken conveying device and its working method shown include: a bracket assembly 1, a Z-axis lifting assembly 2, an X-axis moving assembly, a first servo motor 4, a second servo motor 5, and a third servo motor 6. The fourth servo motor 7, the box feeding device, the detection and positioning device, the electrical cabinet 9, the storage cabinet, the base 11, the infrared scanning device 12, the moving roller 13, the control panel 14, the X gear group 15, and the transmission link 16.

[0033] Among them, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com