Lithium battery membrane trimming and taking-up equipment and method thereof

A lithium battery diaphragm and edge trimming technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as uneven edges and burrs, and achieve the effect of flat film rolls, avoiding deformation, and avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of this patent is preferably described in detail below in conjunction with specific embodiments.

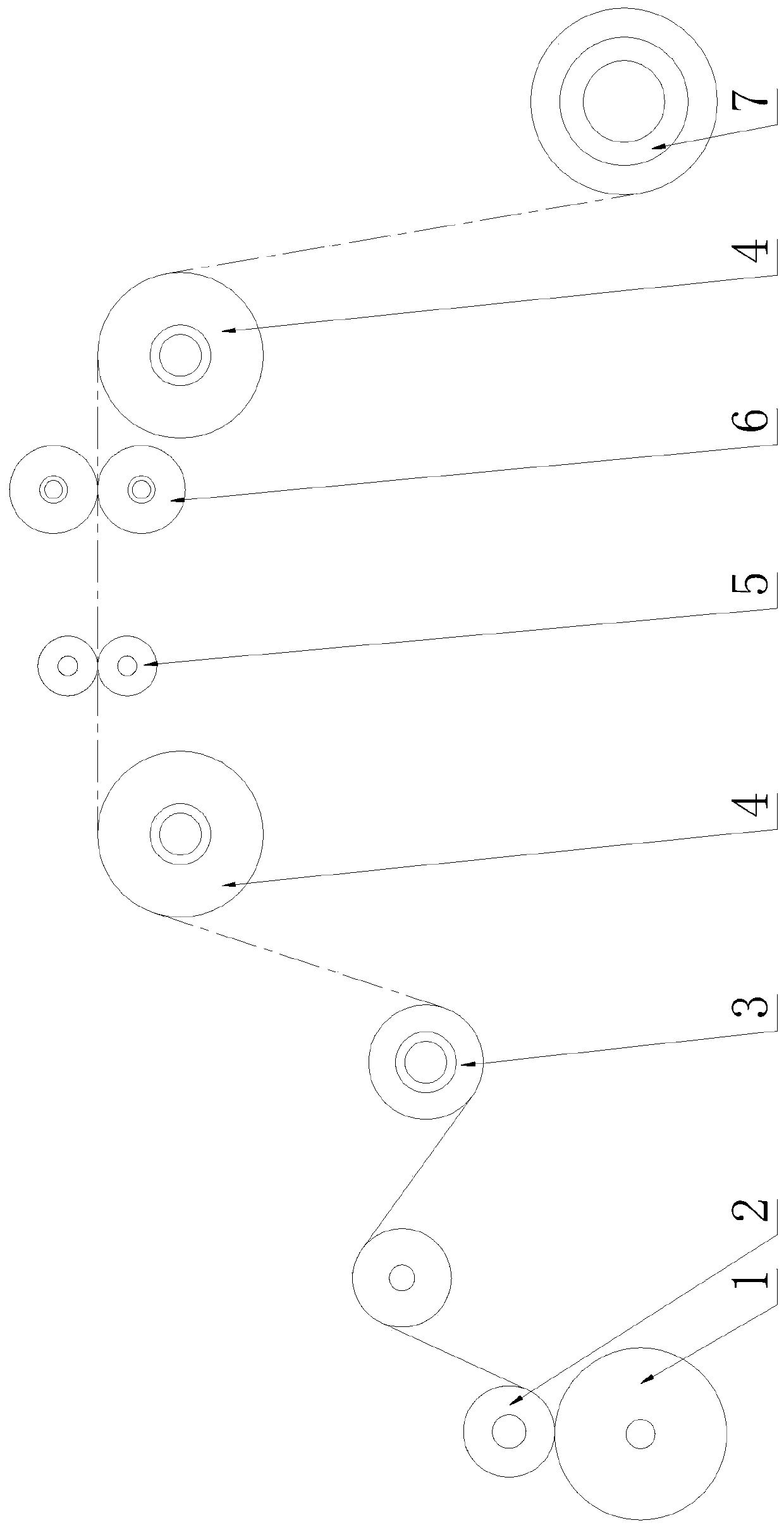

[0041] see Figure 1-8 , a lithium battery diaphragm trimming and winding device, including a traction mechanism, a flattening mechanism, a shaping mechanism and a winding mechanism, the traction mechanism includes a traction roller 1 and a pressure roller 2 on the top of the traction roller 1; the flattening mechanism includes an arc shaped flattening roller 3; the shaping mechanism includes two follow-up rollers 4 and an extension mechanism 5 and a trimming mechanism 6 located between the two follow-up rollers 4; the winding mechanism includes a winding roller 7; the diaphragm passes through the traction mechanism Afterwards, it is initially flattened by the curved roller, then flattened again by the shaping mechanism and trimmed, and then the winding is completed by the winding roller 7;

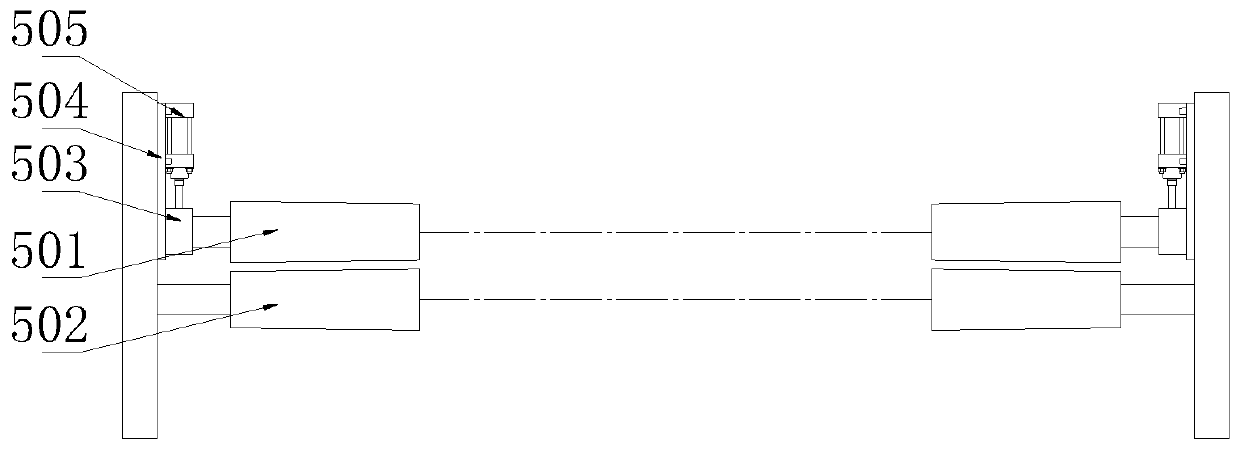

[0042] The stretching mechanism 5 includes a movable stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com