Power maintenance lifting device

A lifting device and power maintenance technology, applied in the direction of cranes, etc., can solve the problems of high precision requirements, low precision, and large components of lifting equipment, so as to achieve unaffected transmission effect, easier control of expansion and contraction, and self-locking effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

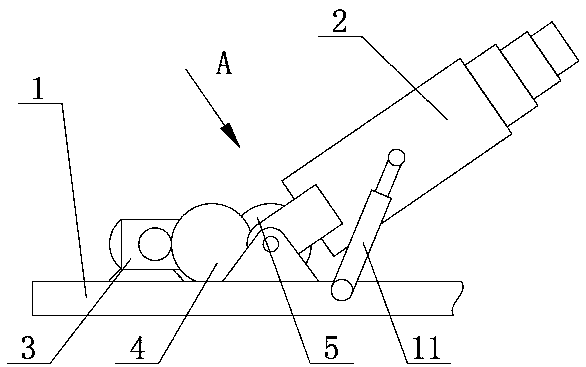

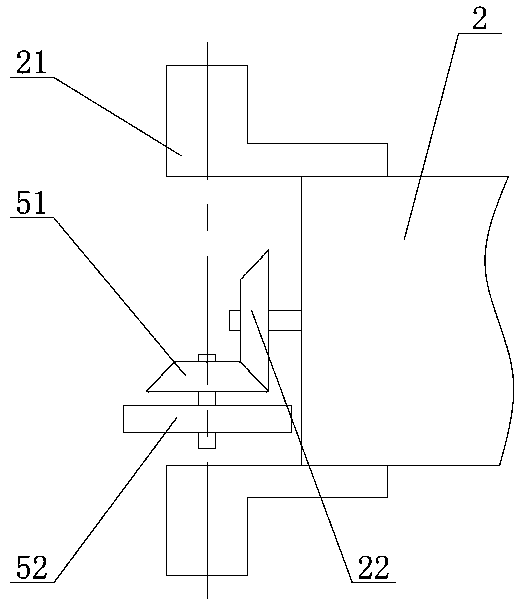

[0025] Such as Figure 1 ~ Figure 3 As shown, a lifting device for electric power maintenance provided by the embodiment of the present invention includes a frame 1, a boom 2 and a motor 3, the boom 2 and the motor 3 are all arranged on the frame 1, and the tail of the boom 2 Rotating parts 21 are arranged on both sides of the end, and the rotating parts 21 are connected to the frame 1 in rotation. There is a space between the rotating parts 21 on both sides. In this space, a reversing device 5 and a first bevel gear 22 are arranged. The reversing device 5 includes a second bevel gear. Bevel gear 51 and driven gear 52, the second bevel gear 51 meshes with the first bevel gear 22, driven gear 52 is connected with motor 3 through reduction gear 4, driven gear 52 is cylindrical gear, driven gear 52 and the second The bevel gear 51 is coaxially fixedly connected and coaxial with the rotation axis of the boom 2 .

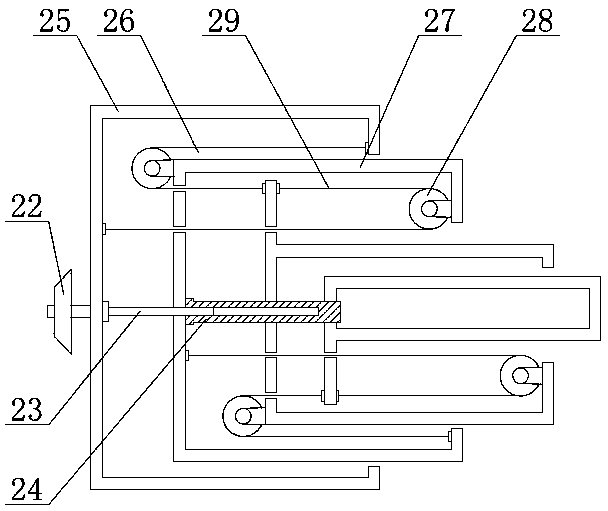

[0026] The first bevel gear 22 is arranged at the tail end of the ...

Embodiment 2

[0036] Such as Figure 4 Figure 5 As shown, in this embodiment, the speed reduction device 4 is a planetary speed reducer, the motor 3 is connected to the third bevel gear 53 through the speed reduction device 4, and the third bevel gear 53 is engaged with the second bevel gear 51 for transmission. The other parts of this embodiment are consistent with the implementation Example 1 is basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com