Embroidery machine good in frame movement stability, driving device for frame and bridge auxiliary rail

A stable, embroidery machine technology, applied in the direction of embroidery machine, feeding device, embroidery machine mechanism, etc., can solve the problems that need to be further improved, and achieve the effect of compact structure, small vibration influence, and reduced jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

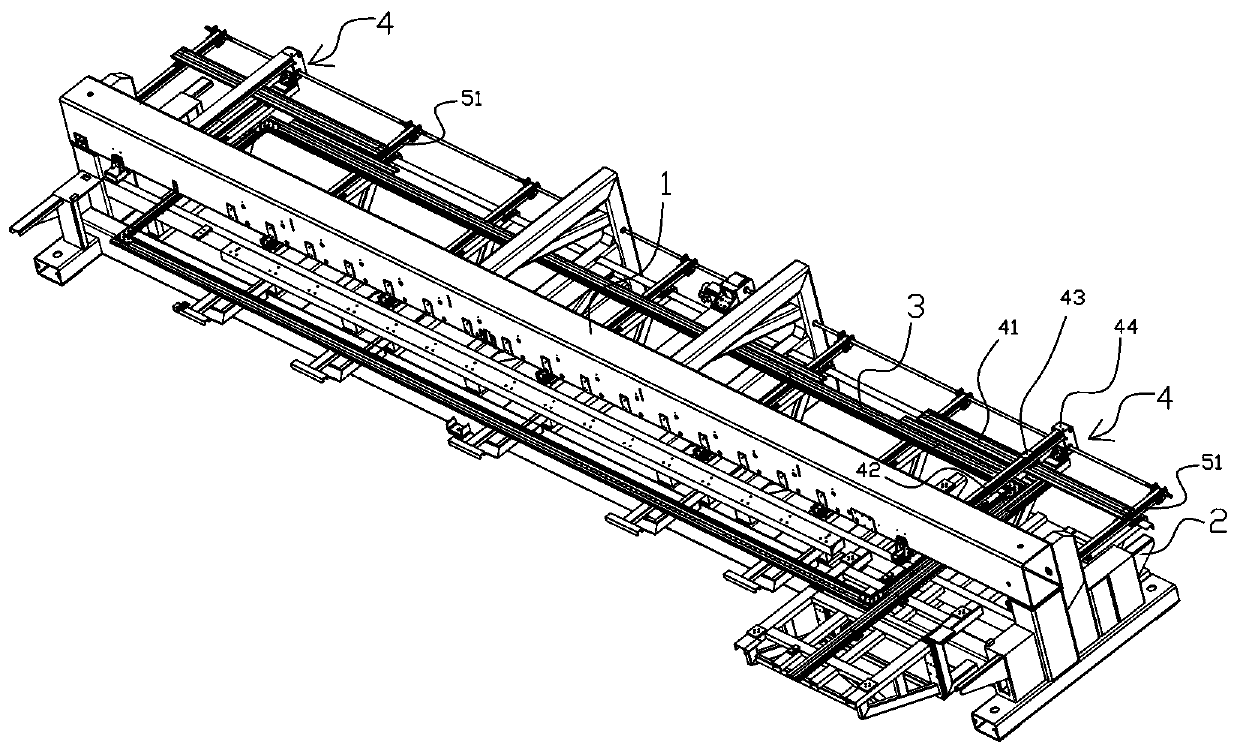

[0037] Such as figure 1 As shown, this embodiment provides an embroidery machine with good frame movement stability, including:

[0038] The frame includes a crossbeam 1 and a frame lower body 2 located below the crossbeam 1; the crossbeam 1 is erected with the frame lower body 2;

[0039] The mobile frame 3 is movably arranged above the lower body 2 of the frame;

[0040] The bridge sub-rail 4 is connected with the moving frame 3 for driving the moving frame 3 to move on the lower body 2 of the frame, and it includes a side end of the moving frame 3 for driving the moving frame 3 The synchronously moving auxiliary rail 41 extending along the first direction, the bridge auxiliary rail driving guide rail 42 located above the auxiliary rail 41 extending along the second direction perpendicular to the first direction, and the auxiliary rail driving guide rail 42 arranged on the bridge auxiliary rail The bridge driving trolley 43 on the guide rail 42 and the bridge auxiliary rai...

Embodiment 2

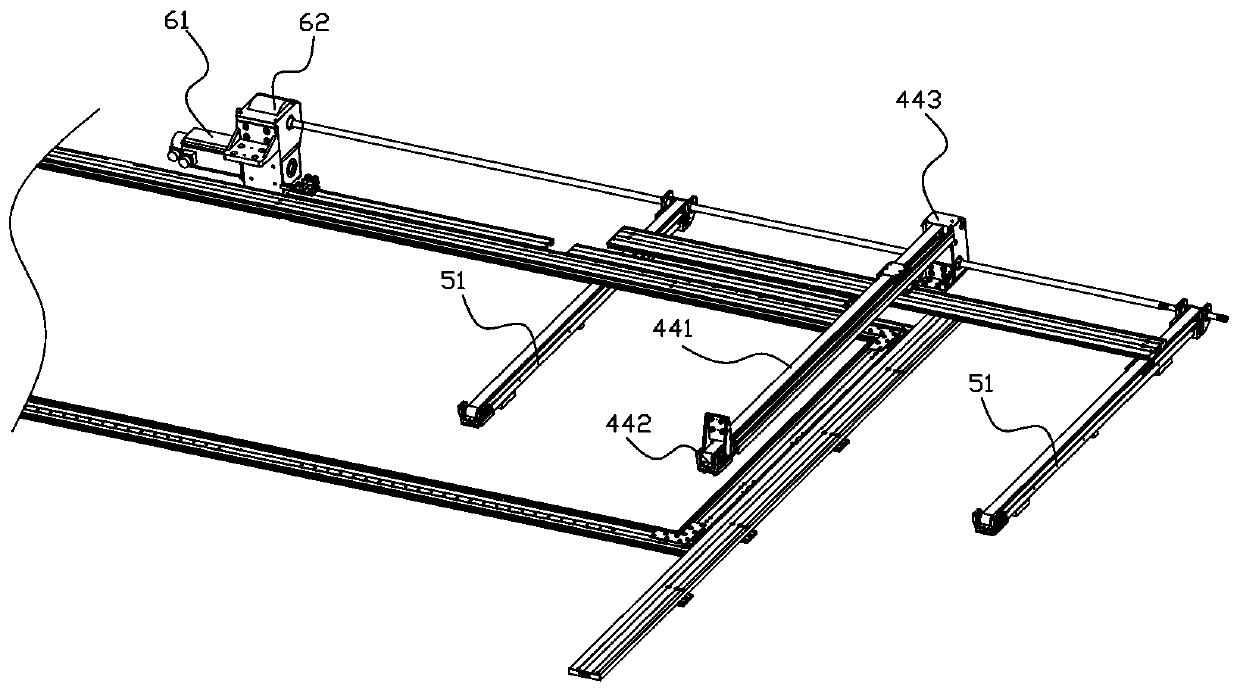

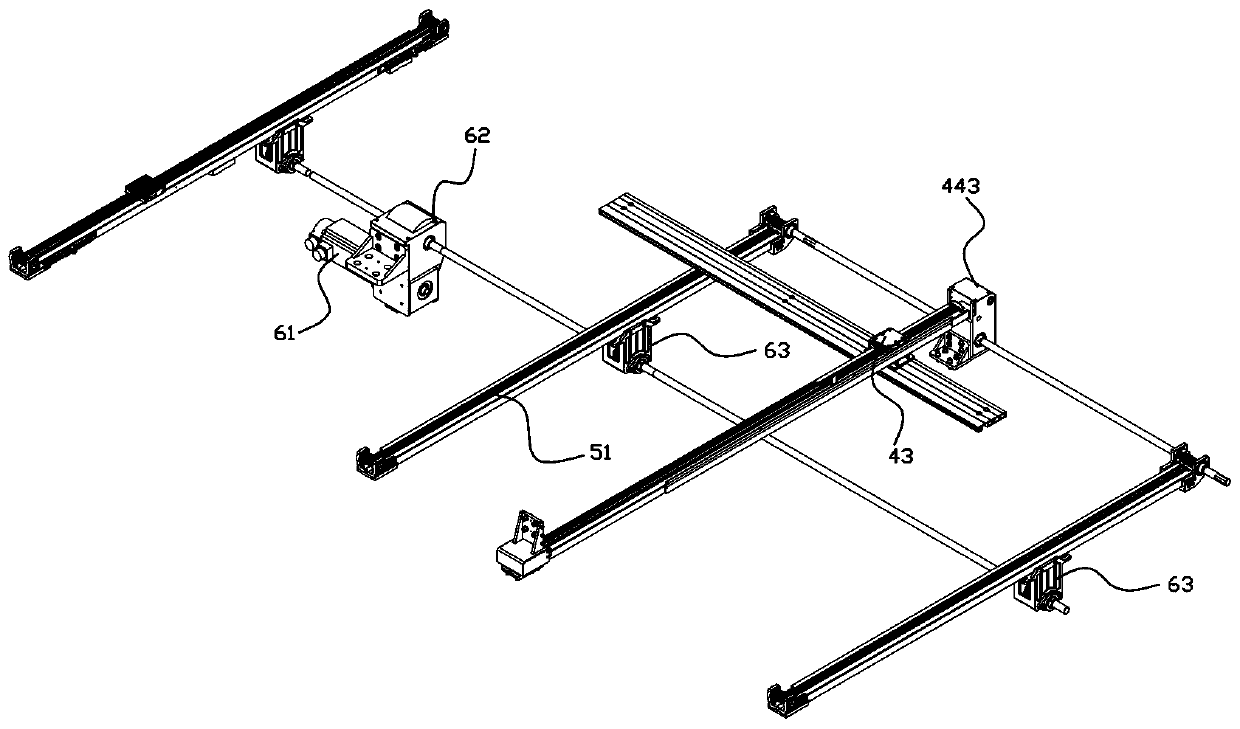

[0051] Such as figure 2 , image 3 , Figure 4 As shown, in this embodiment, the auxiliary rail 4 of the bridge frame cooperates with the Y drive to realize the movement of the moving frame 3 along the Y stroke direction, specifically, as figure 2As shown, the embroidery machine in this embodiment also includes a drive motor 61 and a drive motor transmission box 62 connected to the rotating shaft of the drive motor 61, and the two sides of the bridge sub-rail transmission box assembly 44 are respectively connected to each other by a transmission shaft. A pulley driven by the Y is connected, and a pulley driven by the Y is connected with the drive motor transmission box 62 through a transmission shaft rod, and through the design of the drive motor transmission box 62, the power output of the drive motor 61, Simultaneously act on the belt pulley of bridge auxiliary rail transmission box assembly 44 and Y drive. The above-mentioned design makes it possible to ensure the high...

Embodiment 3

[0067] Such as Figure 5As shown, this embodiment provides a driving device for an embroidery machine frame, including: a Y drive and a bridge sub-rail 4 arranged between the two Y drives, and the bridge sub-rail 4 includes a bridge extending along the first direction. The auxiliary rail 41, the bridge auxiliary rail driving guide rail 42 extending along the second direction perpendicular to the first direction above the auxiliary rail 41, the bridge driving trolley 43 arranged on the bridge auxiliary rail driving guide rail 42 and the The bridge auxiliary rail transmission box assembly 44 used to transmit power to drive the bridge driving trolley 43 to move along the extension direction of the bridge auxiliary rail driving guide rail 42 on the bridge auxiliary rail driving guide rail 42, the bridge driving trolley 43 and the bridge auxiliary rail driving guide rail 42 The center of the auxiliary rail 41 is connected, preferably through a connecting block and the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com