Surface cleaning device of wind electricity blade

A surface cleaning device and technology for wind power blades, applied in wind power generation, wind turbines, machines/engines, etc., can solve the problems of high installation height, bulky blades, time-consuming and labor-intensive, etc., and achieve easy operation, high cleaning quality, Automatically merge the effect of dust on the blade surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

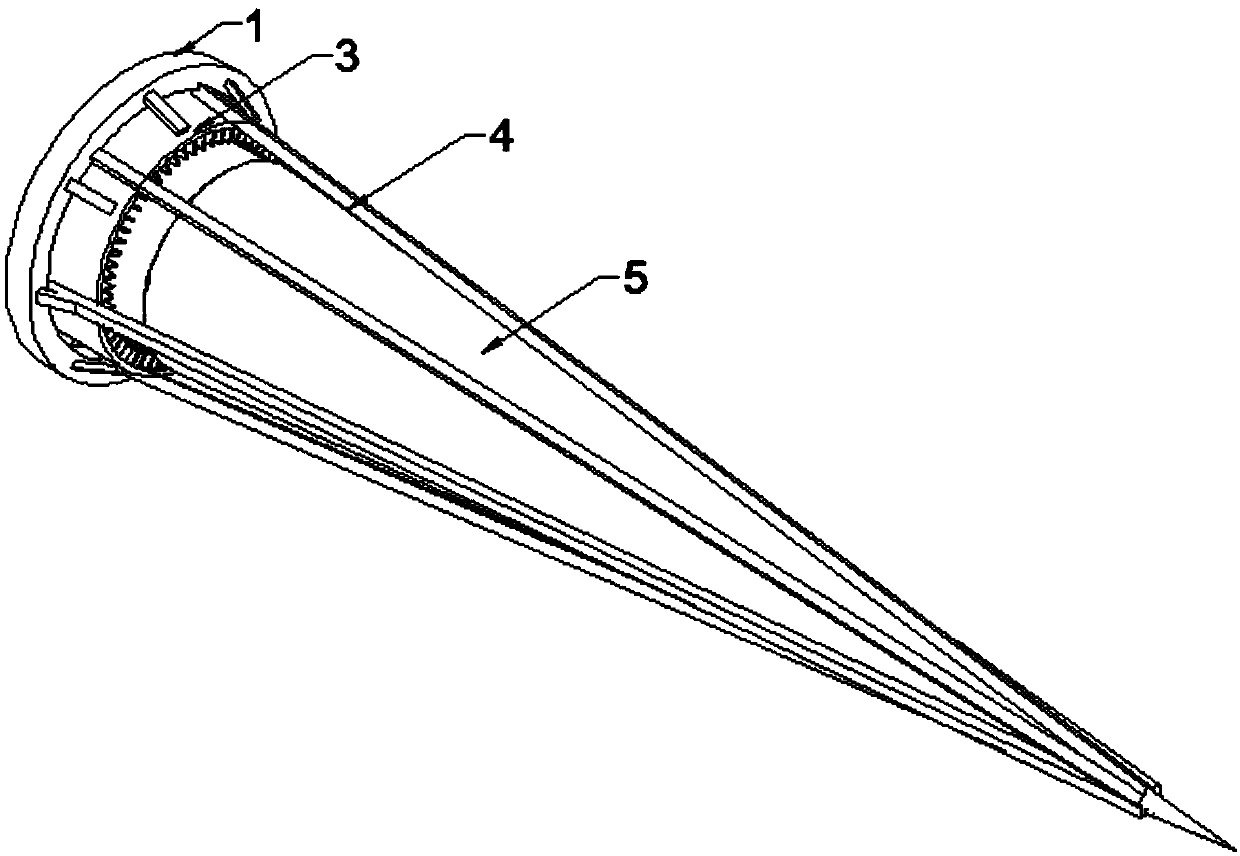

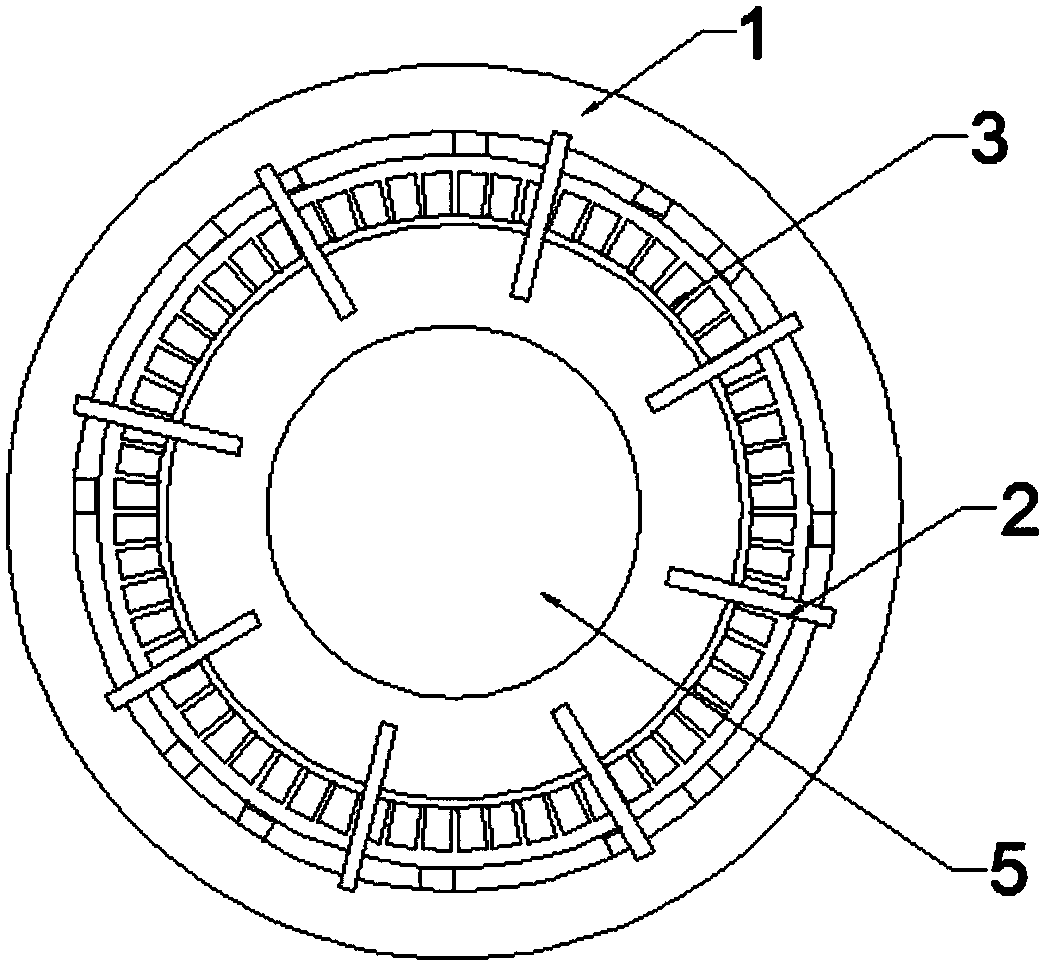

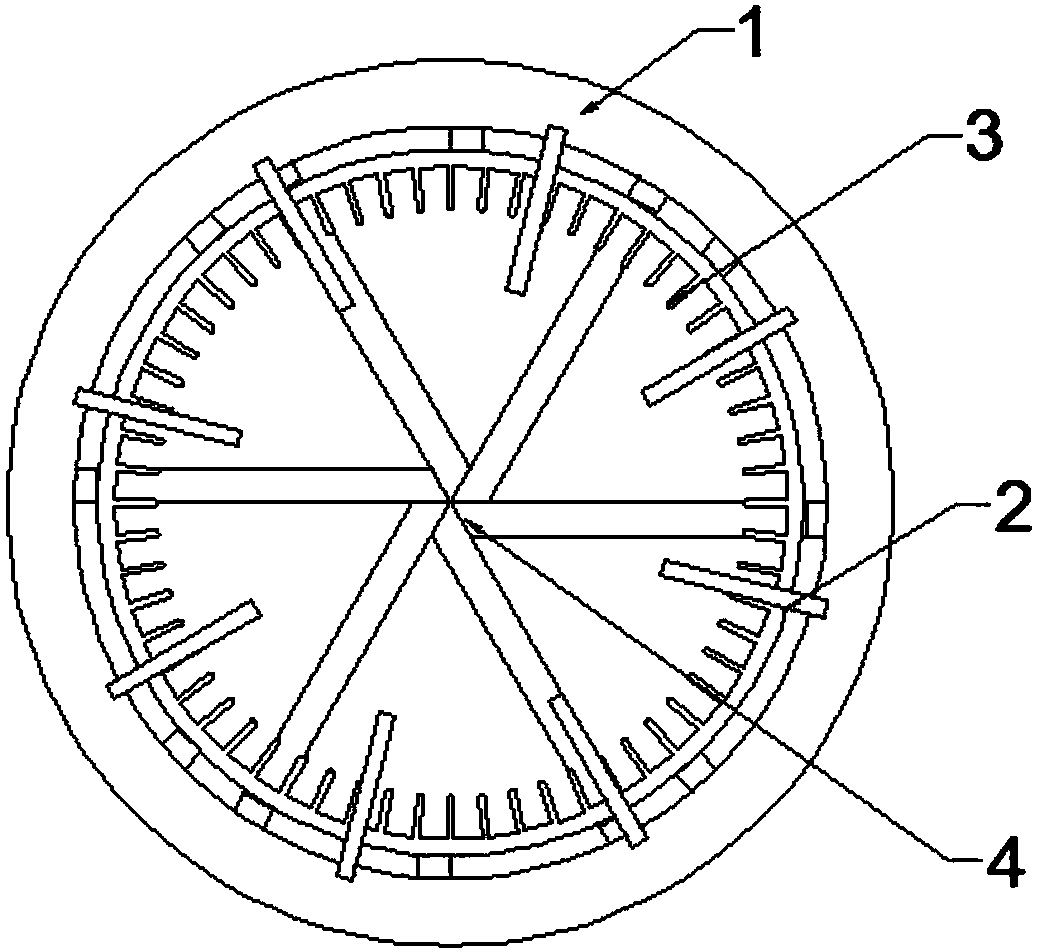

[0018] Such as Figure 1-3 As shown, a wind turbine blade surface cleaning device includes a cleaning assembly 3, and a chute is provided on the outer side of the cleaning assembly 3 along the circumferential direction. A slide rail 4 is slidably connected in the chute. The slide rail 4 traverses the left and right ends of the blade 5 of the wind power generation equipment, and the slide rail 4 is fixedly connected to the blade 5 by bolts. The cleaning assembly 3 can run accurately along the surface of the blade 5 through the guiding function of the slide rail 4 .

[0019] In order to ensure that the wind turbine blade surface cleaning device can be stably installed on the installation end of the blade 5 , a mounting plate 2 is screwed on the outside of the cleaning assembly 3 , and a chuck is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com