Efficient mop cleaning and dewatering all-in-one machine

A mop cleaning and all-in-one technology, which is applied to centrifuges, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as difficult operation and large volume of the cleaning machine, and achieve reduced workload, small volume, and thorough cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

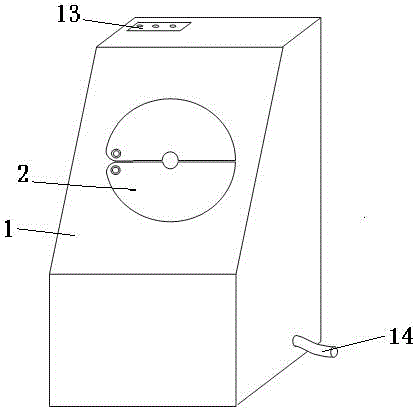

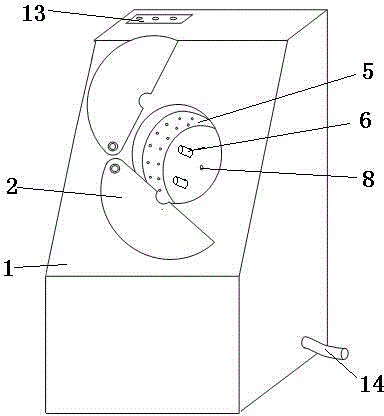

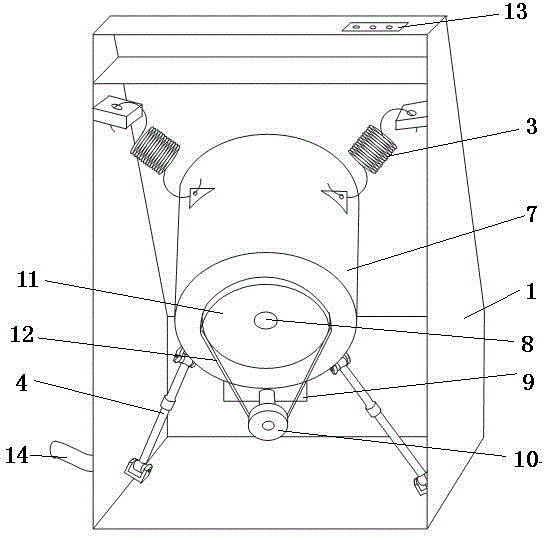

[0034] A high-efficiency mop cleaning and dehydrating machine of this patent includes a housing 1, upper and lower cover plates 2, two tension springs 3, two shock absorbers 4, an outer cylinder 7, an inner cylinder 5, a positioning column 6, a rotating shaft 8, Bearing, motor 9, driving wheel 10, driven wheel 11, electromagnetic stop device; the front of the housing 1 is provided with an inclined cleaning port; the upper and lower cover plates 2 are arranged on the housing 1 to seal the cleaning port, and the linkage cover Seals are provided between the plate and the cleaning port, between the outer cylinder 7 and the housing 1; the tension spring 3 connects the upper part of the outer cylinder 7 and the housing 1, and the two ends of the shock absorber 4 are respectively connected to the housing 1 The lower part and the outer cylinder 7 are fixed in the housing 1 through the tension spring 3 and the shock absorber 4; the mouth of the inner and outer cylinder 7 is coaxial with...

Embodiment 2

[0045] The other structures of this embodiment are the same as in Embodiment 1, but the bearing of the mop knot is fixedly arranged at the lower end of the mop rod, the rotating shaft is fixed in the bearing, and the rotating shaft is fixedly connected with the mop head; the mop structure of this patent can also be: the mop rod is divided into In the upper section and the lower section, the bearing is arranged in one section, the rotating shaft is fixed in the bearing, and the other mop rod is connected with the rotating shaft.

Embodiment 3

[0047] The other structures of this embodiment are the same as those of Embodiment 1, but the motor 9 is also provided with a reverse braking mechanism, and the bottom of the inner cylinder 5 is provided with multiple rows of water inlet holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com