Magnetorheological damper piston assembly with sedimentation active dispersing device

A technology of magnetorheological damper and piston assembly, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc. The effect of energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

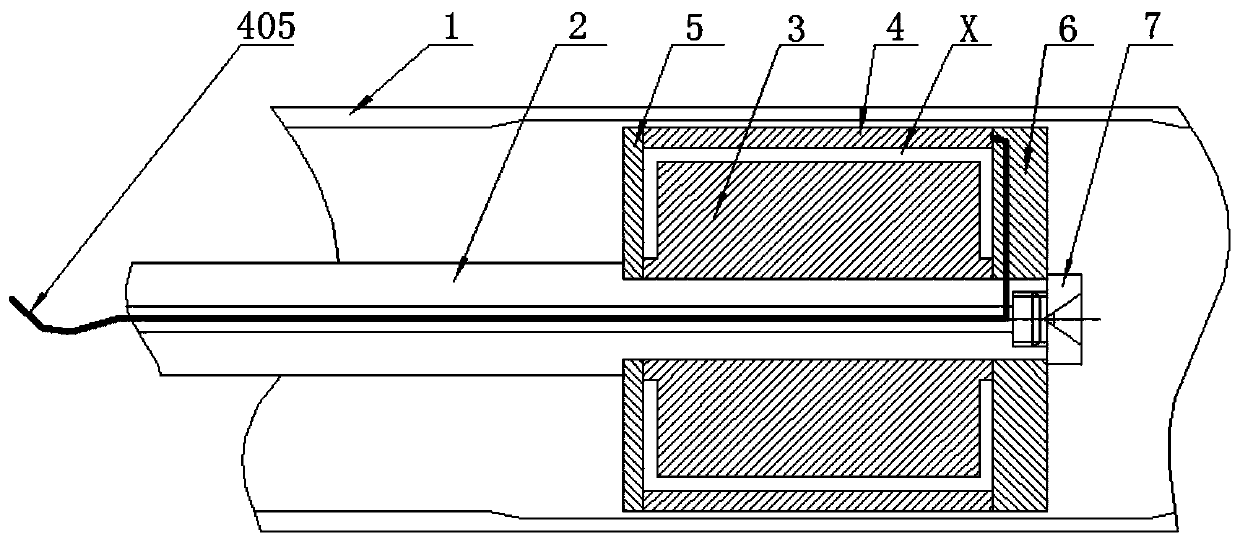

[0045] see figure 1 , a magneto-rheological damper piston assembly with a sedimentation active dispersion device, characterized in that it includes a working cylinder 1, a piston rod 2 and a piston assembly.

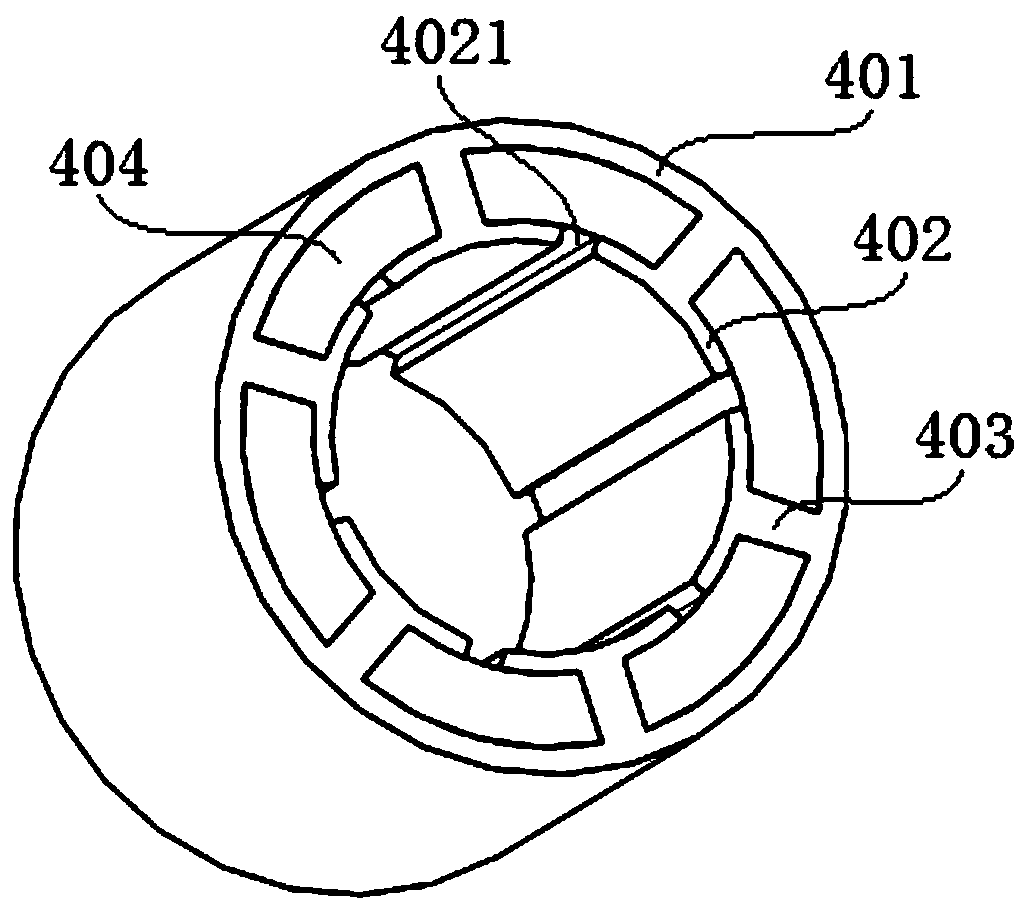

[0046] see Figure 4 , the working cylinder 1 is cylindrical. There are several through grooves I101 and several through holes I102 evenly distributed around the circumference of the working cylinder 1 , wherein the through grooves I101 are located on the inner surface of the working cylinder 1 , and its position is recorded as the balance position of the working cylinder 1 . The working cylinder 1 is filled with magnetorheological fluid.

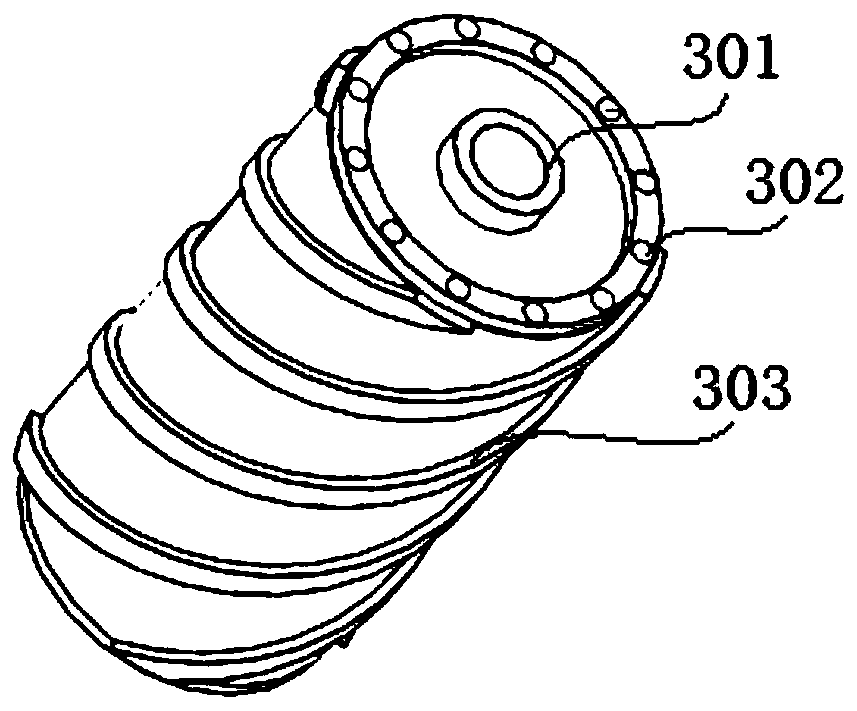

[0047] see Figure 7 , the piston rod 2 is a hollow cylinder. The inner wall of the upper end of the piston rod 2 is processed with threads. A plurality of lead grooves I201 are opened on the end surface of the upper end of the piston rod 2 . The upper end of the piston rod 2 penetrates the inside of the working cylinder 1, and ...

Embodiment 2

[0070] see figure 1 , a magneto-rheological damper piston assembly with a sedimentation active dispersion device, characterized in that it includes a working cylinder 1, a piston rod 2 and a piston assembly.

[0071] see Figure 4 , the working cylinder 1 is cylindrical. Several through grooves I101 and several through holes I102 are uniformly distributed around the working cylinder 1 , wherein the through grooves I101 are located on the inner surface of the working cylinder 1 , and its position is recorded as the balance position of the working cylinder 1 . The working cylinder 1 is filled with magnetorheological fluid.

[0072] see Figure 7 , the piston rod 2 is a hollow cylinder. The inner wall of the upper end of the piston rod 2 is processed with threads. A plurality of lead grooves I201 are opened on the end surface of the upper end of the piston rod 2 . The upper end of the piston rod 2 penetrates the inside of the working cylinder 1, and can reciprocate inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com