Regeneration method for coked iridium-containing catalyst

A catalyst and catalyst bed technology, applied in chemical instruments and methods, physical/chemical process catalysts, bulk chemical production, etc., can solve the problems of commercialization restrictions, difficult redispersion, low space velocity, etc., to reduce operating harshness The effect of speed, simplification of operation steps and recovery of reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

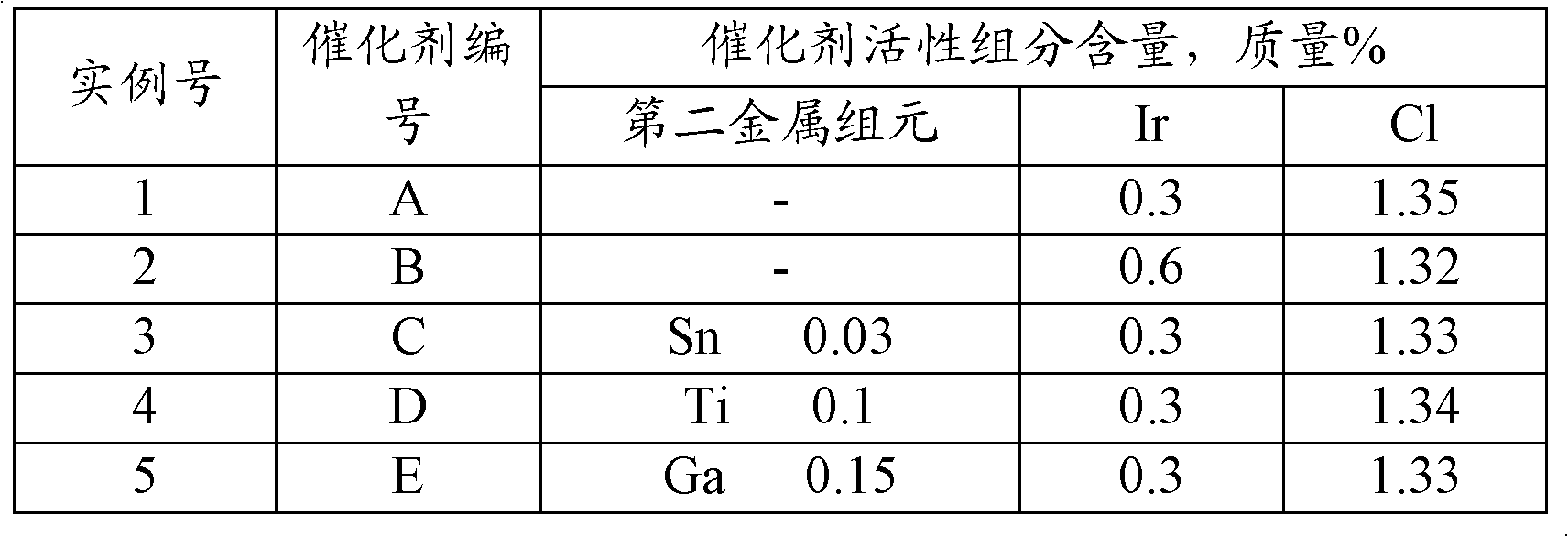

[0028] Preparation of iridium-containing catalysts.

[0029] Get 100 grams of γ-alumina carriers, use the mixed solution prepared by chloroiridic acid and hydrochloric acid as the impregnating solution and impregnate at 25° C. for 8 hours. The aluminum carrier is used as a benchmark for calculation, the same below), and deionized water is added to make the liquid / solid volume ratio 1.2. After impregnation, dry the solid at 120°C for 12 hours, treat it for 4 hours at 510°C, air / agent volume ratio 1200 / 1, and water / chlorine molecular ratio 40 / 1, then dry it at 500°C, air / agent Under the condition of volume ratio of 500 / 1, it was reduced with hydrogen for 4 hours to obtain catalyst A, whose active component content is shown in Table 1.

example 2

[0031] Catalyst B was prepared according to the method of Example 1, except that the impregnating solution used contained 0.6% by mass of Ir, and the active component content of catalyst B was shown in Table 1.

example 3

[0033] Catalyst C was prepared according to the method of Example 1, except that tin tetrachloride was added in the impregnating solution, so that the impregnating solution contained 0.03 mass % of Sn and 0.3 mass % of Ir. The active component content of the obtained catalyst C was shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com