Dispersion method of graphene

A graphene dispersion, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of high cost, poor dispersion stability, low graphene concentration, etc., and achieve low cost and simple method. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 1.0g alkali lignin and dissolve in 50.0mL sodium hydroxide aqueous solution, add 1.0g graphene powder. After magnetic stirring at room temperature for 24 hours, then 200W ultrasonic dispersion for 12 hours, finally neutralized with hydrochloric acid and filtered, the filter cake was vacuum-dried to obtain lignin / graphene composite powder.

[0032] Disperse the lignin / graphene composite powder in the aqueous solution of sodium hydroxide according to different concentrations, ultrasonically disperse for 0.5h, and test its dispersion effect in the aqueous solution of sodium hydroxide, as shown in Table 1. As can be seen from Table 1, pure graphene powder cannot be dispersed in the aqueous solution of sodium hydroxide, and when the concentration of lignin / graphene composite powder (pH value is 8-10) in the aqueous solution of sodium hydroxide is less than or When it is equal to 10 mg / mL, a stable graphene dispersion can be formed in an aqueous solution of sodium hydrox...

Embodiment 2

[0036] Take 2.0g alkali lignin and dissolve in 50.0mL formaldehyde solution, add 1.0g graphene powder. After magnetic stirring at room temperature for 6 hours, 200W ultrasonic dispersion was performed for 12 hours, the dispersion was precipitated with isopropanol and then filtered, and the filter cake was vacuum-dried to obtain a lignin / graphene composite powder.

[0037] The lignin / graphene composite powder was added to the aqueous solution of sodium hydroxide according to different concentrations, ultrasonically dispersed for 0.5h, and its dispersion effect in the solution was tested, as shown in Table 2. As can be seen from Table 2, pure graphene powder cannot be dispersed in the aqueous solution of sodium hydroxide, and when the concentration of lignin / graphene composite powder (pH value is 8-10) in the aqueous solution of sodium hydroxide is less than or When it is equal to 15 mg / mL, a stable graphene dispersion can be formed in an aqueous solution of sodium hydroxide.

...

Embodiment 3

[0041] Take 1.0g sodium lignosulfonate and dissolve it in 50.0mL deionized water, add 2.0g graphene powder. After magnetic stirring at room temperature for 6 hours, 150W ultrasonic dispersion was performed for 12 hours, the dispersion was precipitated with isopropanol and then filtered, and the filter cake was vacuum-dried to obtain a lignin / graphene composite powder.

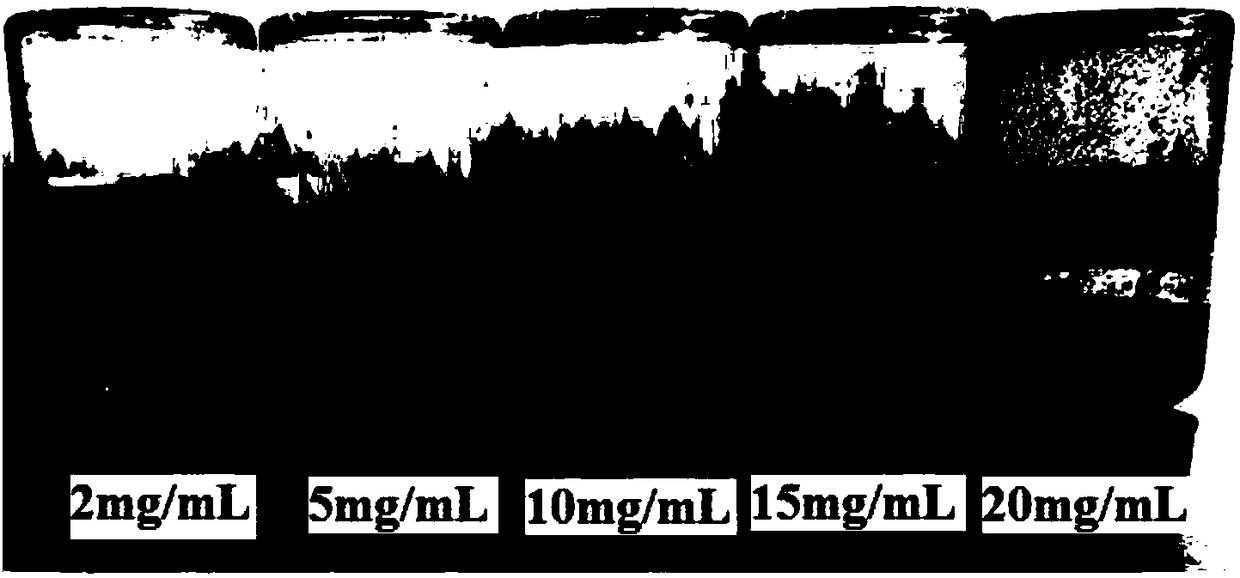

[0042] Add the lignin / graphene composite powder to deionized water according to different concentrations, ultrasonically disperse for 0.5h, and check its dispersion effect in the solution, as shown in Table 3 and figure 1 shown. from Table 3 and figure 1 It can be known that pure graphene powder cannot be dispersed in water, but when the concentration of lignin / graphene composite powder in water is less than or equal to 15 mg / mL, a stable graphene dispersion can be formed in water.

[0043] Table 3. Dispersion effect of lignin / graphene composite powder in water

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com