Special-shaped single-row one-gear hybrid device

A hybrid and special-shaped technology, which is applied to electric components, transmission devices, gear transmission devices, etc., can solve the problems of many assembly restrictions and difficult assembly of the planetary row structure, and achieve simplified structure, improved performance, and optimized gear tooth profile. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

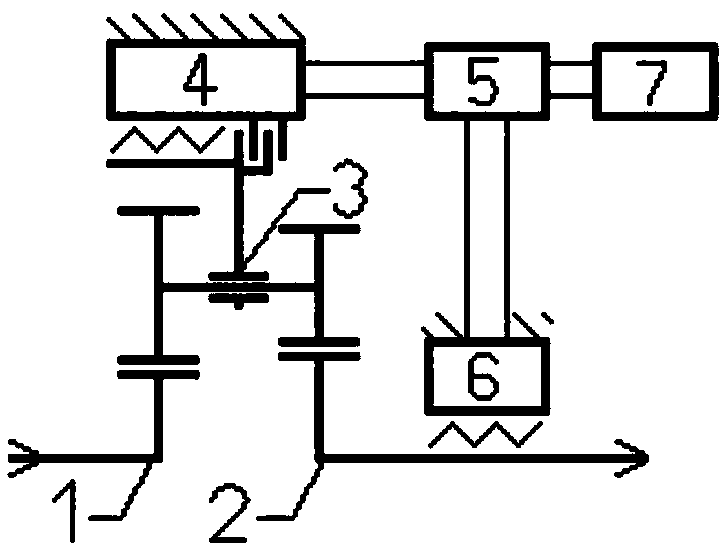

[0022] Embodiment 1: The transmission mechanical form of the special-shaped single-row first-speed mixer of the present invention—a single-variable linear speed planetary-row mixer is also Embodiment 1 of the present invention. see figure 1 . The planetary row in the transmission machinery is a single-variable linear speed planetary row (in this embodiment, the single-variable linear speed planetary row structure form six, but also other three structural forms): the input end is the left central wheel, and the z number of teeth is the Zz speed Nz, the output end is the number of teeth of the right center wheel y ring is Zy speed Ny, and the controlled end is the speed Nj of planet carrier j with variable linear speed planetary gear. The control system is a parallel device of a brake and an electromagnetic induction motor, an induction motor, a control circuit, a storage battery and an external power plug, etc. Let the number of teeth of the right set of gears of the variable...

Embodiment 2

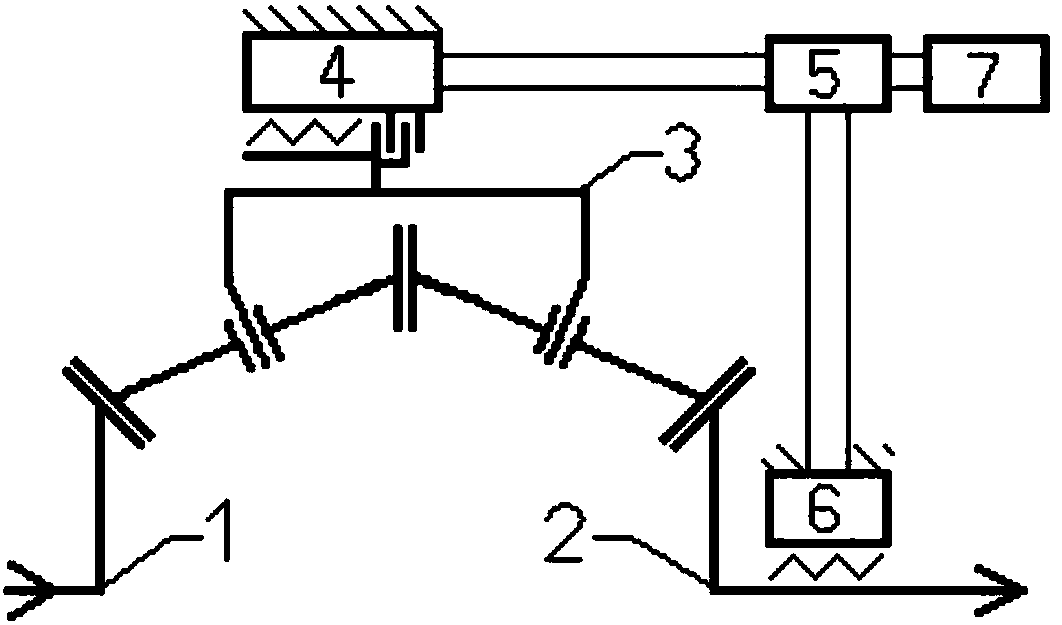

[0024] Embodiment 2: The transmission mechanical form of the special-shaped single-row first-speed mixer of the present invention is a double-single bevel gear double-layer planetary row mixer, which is also embodiment 2 of the present invention. see figure 2 . The planetary row in the transmission machinery is a single-bevel gear double-layer planetary planetary row: the input end is the left center wheel z, the number of teeth is Zz speed Nz, the output end is the right side center wheel y number of teeth is Zy speed Ny, and the controlled end is belt double The rotation speed Nj of the planet carrier j of the layer star planetary gear. The control system is a parallel device of a brake and an electromagnetic induction motor, an induction motor, a control circuit, a storage battery and an external power plug, etc. The characteristic parameter defining the double-layer planetary row of bevel gears is a, a=Zy / Zz, and the double-layer planetary row of bevel gears obeys the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com