Non-bevel gear differential

A technology of differentials and bevel gears, which is applied in the field of differentials with non-bevel gear structures, can solve the problems of difficult manufacturing and large volume of planetary gear differentials, and achieve the effects of wide application range, small size and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

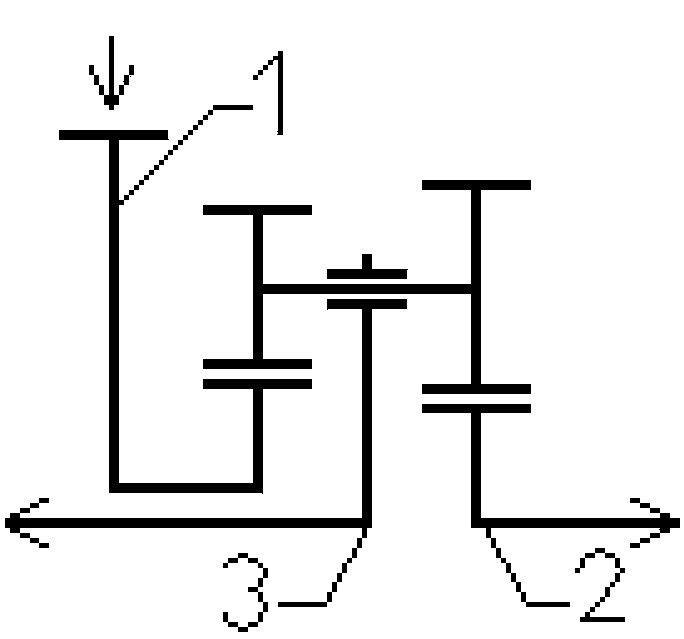

Embodiment 1

[0016] Embodiment 1: Example 1 of the non-bevel gear differential of the present invention A six-non-bevel gear differential with a single-row variable linear speed planetary row structure is also the embodiment 1 of the present invention. Assume that the ratios of the rotational speed ratio and the torque ratio required by the two output terminals are both 1.0. Embodiment 1 The planetary row structure of the transmission machine is a six-single-row planetary row in the form of a variable linear speed planetary row, and all the planetary rows are gears with parallel teeth and non-bevel gears. Assuming that the number of teeth on the right set of gears of the variable line speed planetary gear is Xy, the number of teeth on the other set of gears on the left is Xz, the number of teeth on the left center gear z is Zz, and the number of teeth on the right center wheel y is Zy, then the variable line speed is defined The characteristic parameter of the planetary row is a, a=(Zy*Xz)...

Embodiment 2

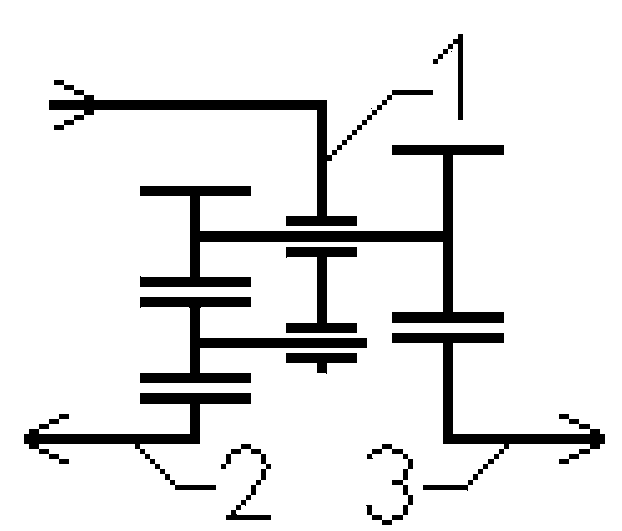

[0017]Embodiment 2: Example 2 of the non-bevel gear differential of the present invention The second non-bevel gear differential is also the embodiment 2 of the present invention. Assume that the ratios of the rotational speed ratio and the torque ratio required by the two output terminals are both 1.0. Embodiment 2 The planetary row structure of the transmission machine is the structural form of the variable linear speed planetary row II single row planetary row, and all the planetary row adopts gears with parallel teeth and non-bevel gear structure. The outer planetary gear on the variable-linear-speed planetary planetary carrier is a variable-linear-speed planetary gear, assuming that the number of teeth of a set of gears on the right side of the variable-linear-speed planetary wheel is Xy, the number of teeth of another set of gears on the left side is Xz, and the center of the left side is The number of teeth of the wheel z is Zz, and the number of teeth of the right cent...

Embodiment 3

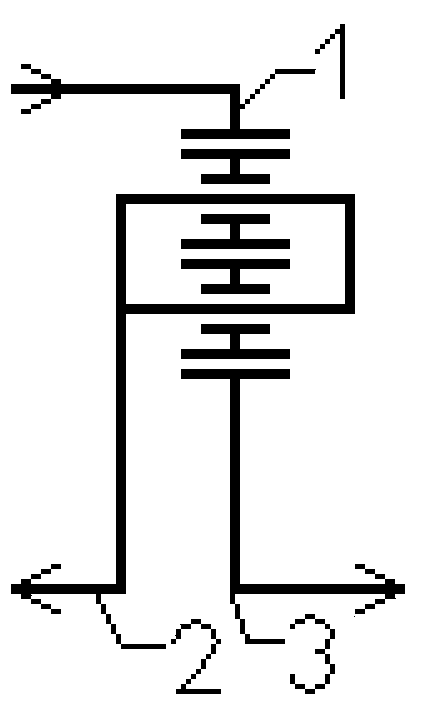

[0018] Embodiment 3: Example 3 of the non-bevel gear differential of the present invention The single-row ordinary double-layer planetary row non-bevel gear differential is also the embodiment 3 of the present invention. Assume that the ratios of the rotational speed ratio and the torque ratio required by the two output terminals are both 1.0. Embodiment 3 The planetary row structure of the transmission machine is an ordinary double-layer planetary row, and all the planetary rows are gears with parallel teeth and non-bevel gear structure. Let the number of teeth of the inner ring gear q be Zq, and the number of teeth of the sun gear be Zt. Then define the characteristic parameter of this variable linear velocity planetary row to be a, a=Zq / Zt, this single-row ordinary double-layer star planetary row obeys its planetary row motion equation and is also its planetary row structural equation Nt-a*Nq-(1- a)*Nj=0, which is Nq-((a-1) / a)*Nj-(1 / a)*Nt=0 after simplification. The coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com