A machine tool equipment resource supply and demand matching method based on a grey correlation algorithm under multivariate quality constraint

A quality-constrained, gray-associated technology, applied in resources, computing, data processing applications, etc., can solve problems such as complex mapping relationships and difficult intelligent matching of supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

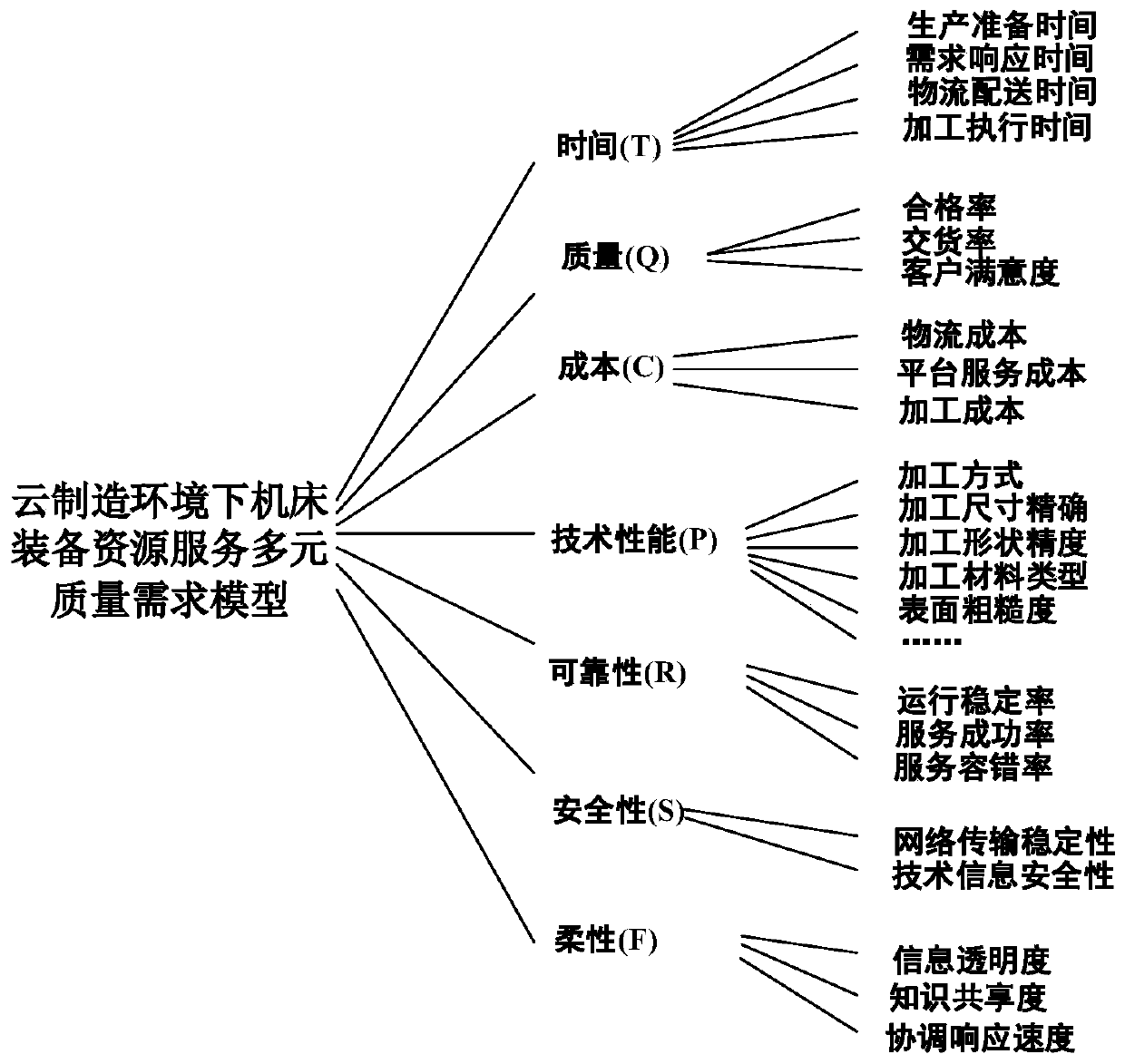

[0054] figure 1 is a seven-dimensional quality requirement model for cloud manufacturing services, such as figure 1 It shows that the seven-dimensional quality requirements such as time T, quality Q, cost C, technical performance P, service reliability R, service security S, and service flexibility F are not independent, but are interrelated. Among them, time T, quality Q, and cost C, as the components of cloud manufacturing service quality requirements, have been studied and analyzed by many researchers, and will not be elaborated here. In view of the characteristics of cloud manufacturing service "centralized service of decentralized resources", the present invention incorporates technical performance P, service reliability R, service security S, and service flexibility F into the consideration dimension of cloud manufacturing service ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com