Current sensing resistor and fabrication method thereof

一种电流感测电阻、电阻器的技术,应用在电阻器安装/支承、加引出端的电阻器、电气测量仪器的零部件等方向,能够解决周围电子组件短路、焊料熔化电阻、变化等问题,达到改进机械强度、佳电性效能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

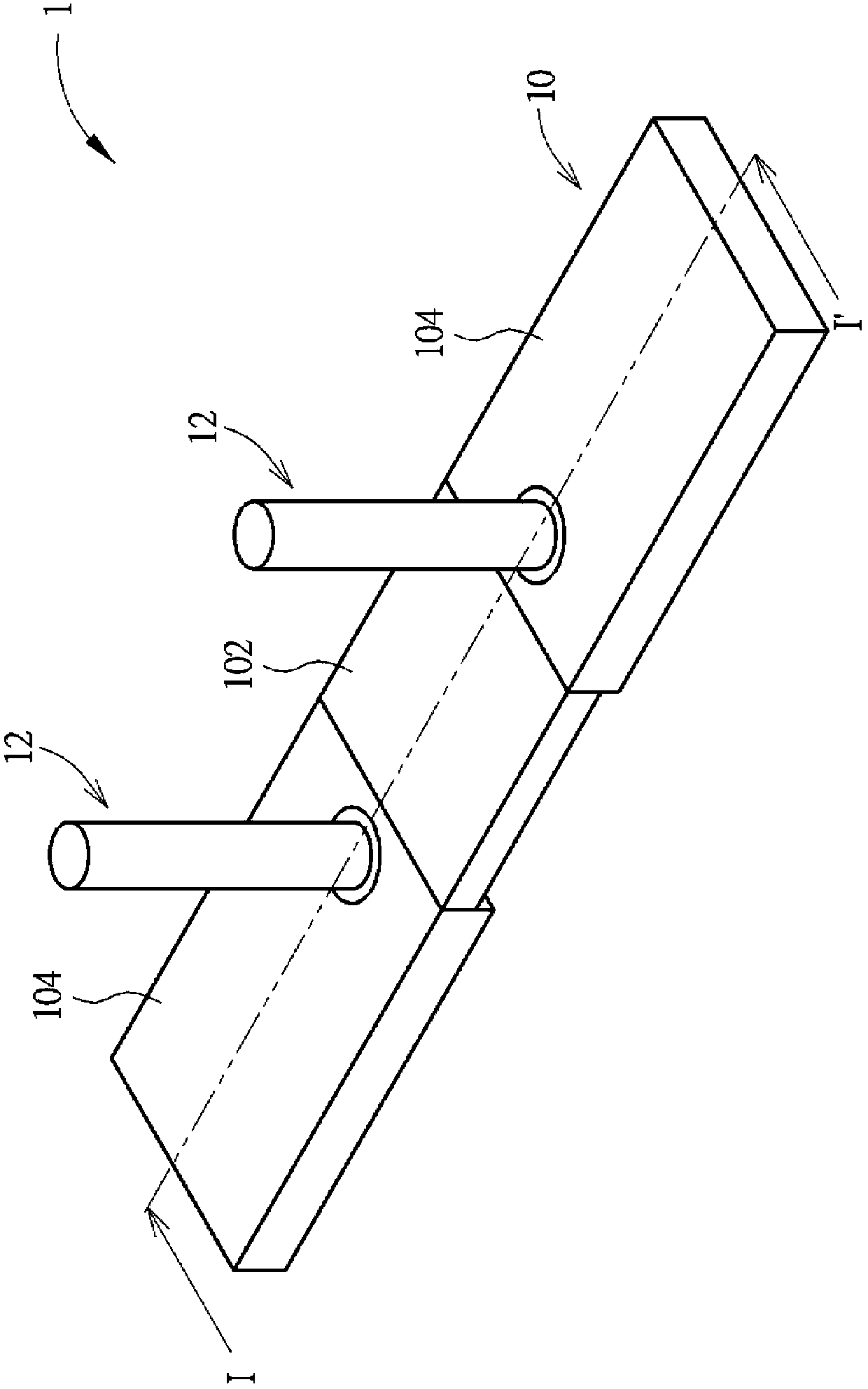

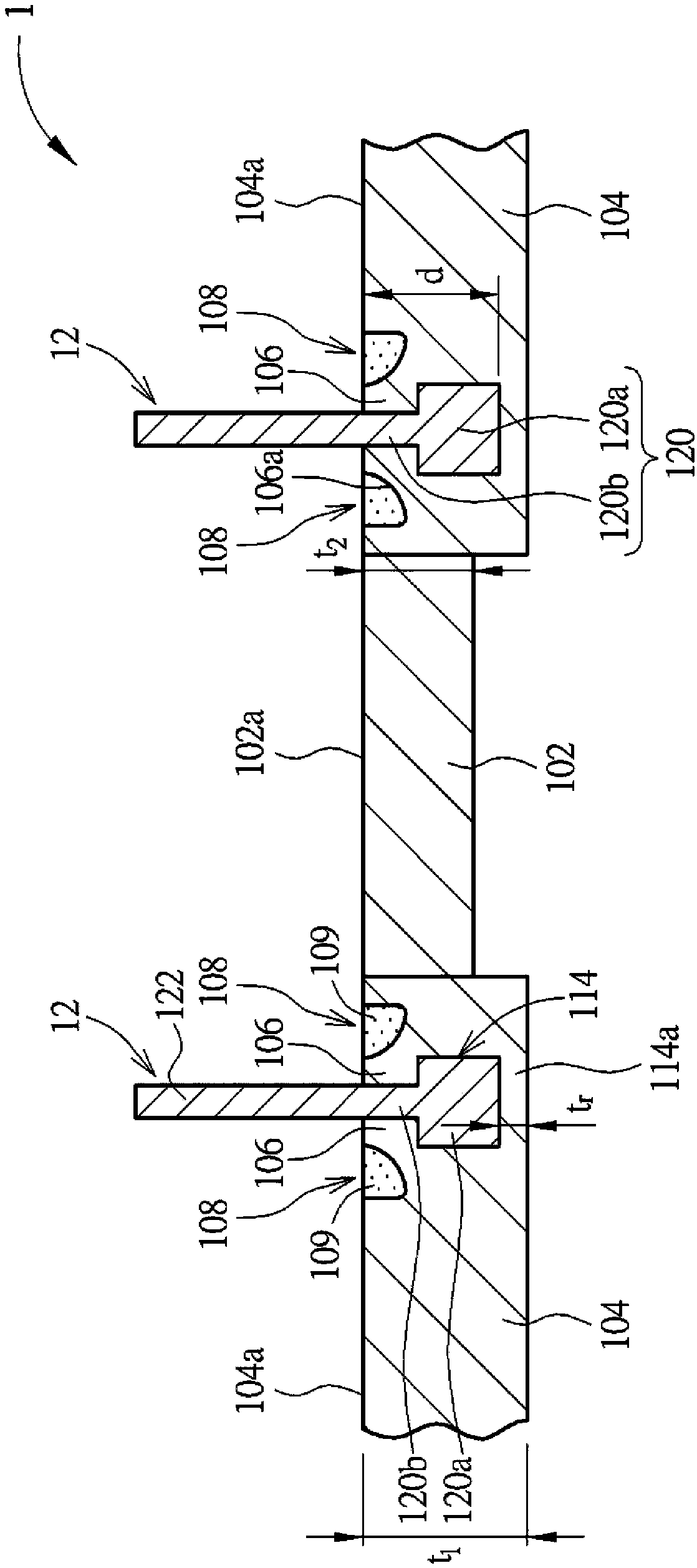

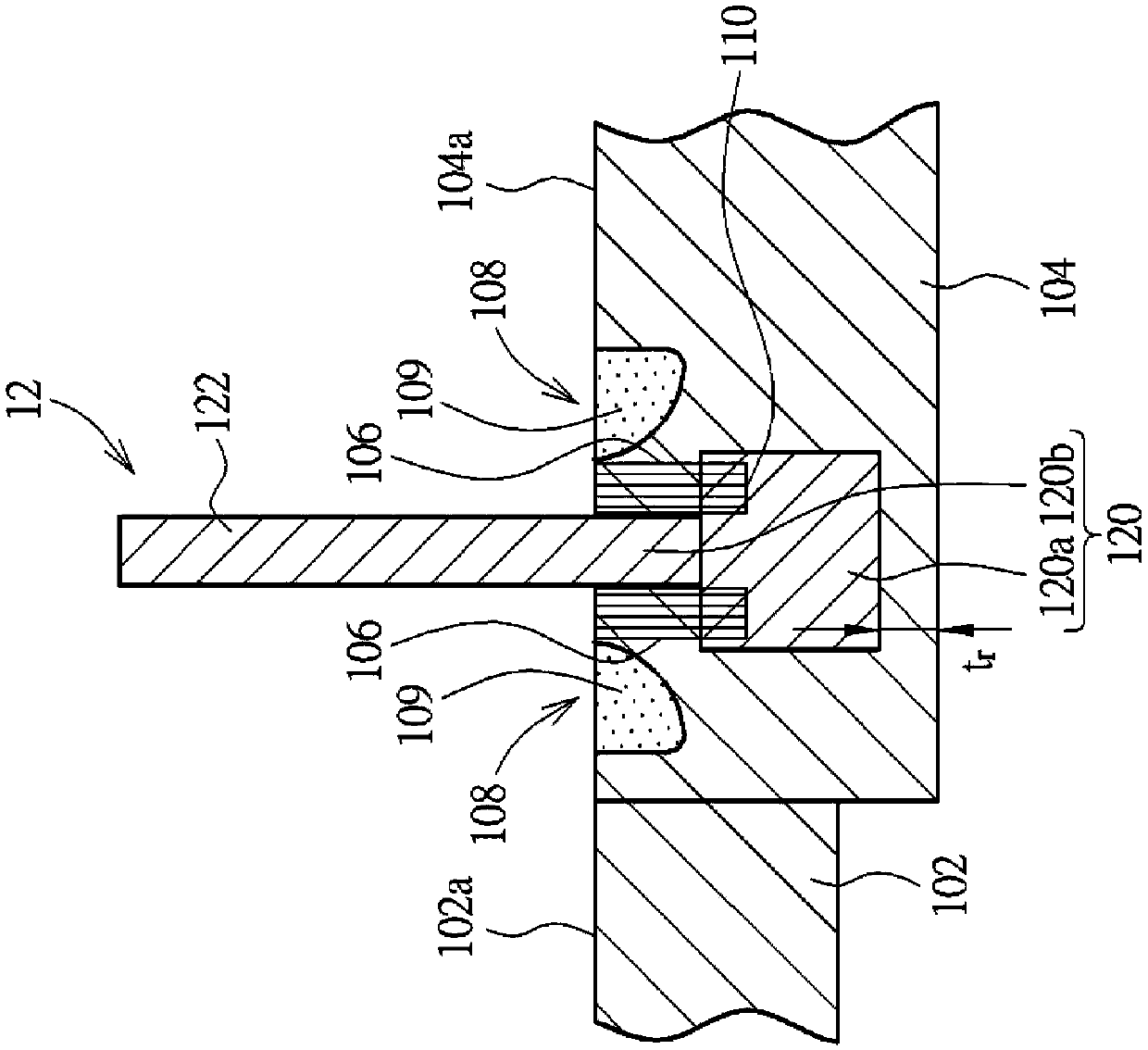

[0039] In the following, details will be explained with reference to the accompanying drawings, the contents of which also constitute a part of the detailed description of the specification, and are shown in a specific example in which the embodiment can be practiced. The following examples are described in sufficient detail to enable one of ordinary skill in the art to implement them. Of course, other embodiments may be implemented, and any structural, logical, or electrical changes may be made without departing from the embodiments described herein. Therefore, the following detailed description should not be taken as limiting, but rather the embodiments contained therein will be defined by the appended claims.

[0040] The drawings illustrating various embodiments of the apparatus are semi-diagrammatic and not drawn to scale, and in particular certain dimensions are for clarity of presentation and are shown exaggerated in the drawings. Also, where multiple embodiments are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com