Preparation method and application of a sn-snsb/carbon nanosheet composite material

A technology of composite materials and carbon nanosheets, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as large difficulties and uncontrollable growth of two-phase materials, and achieve low cost, good industrialization prospects, and improved electrochemistry. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

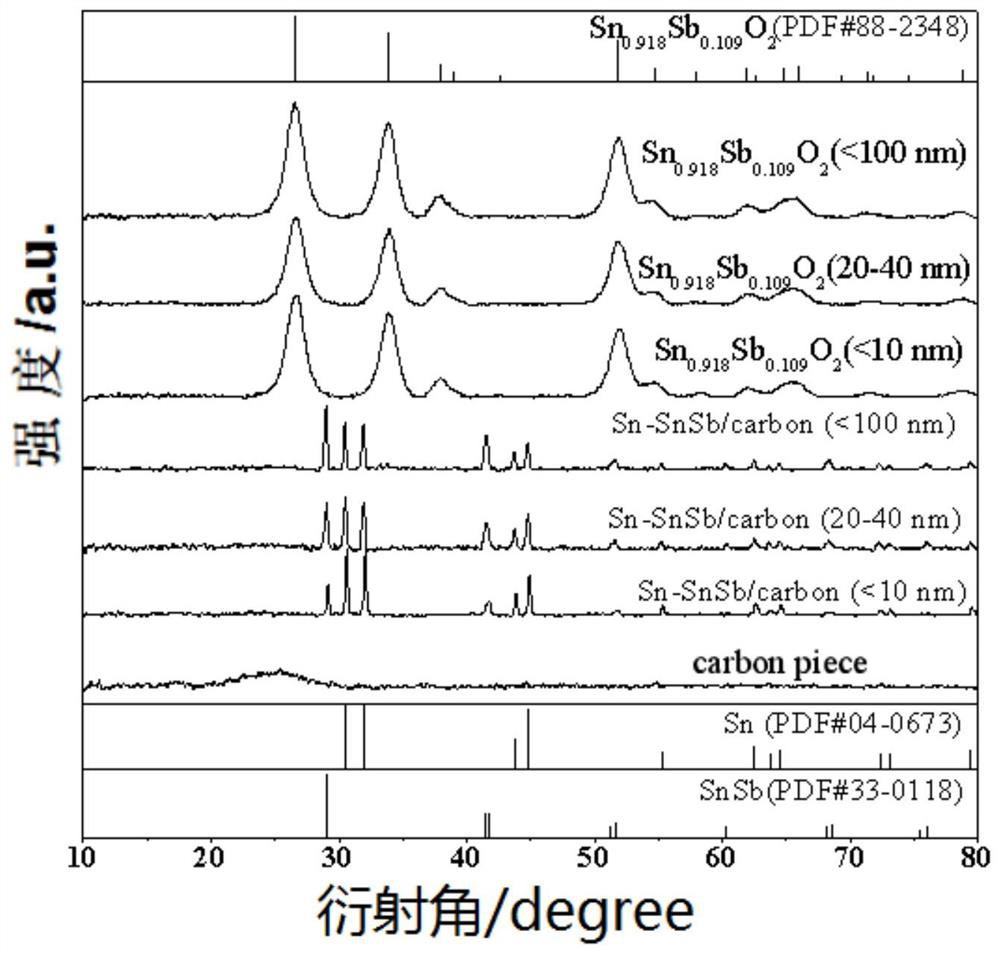

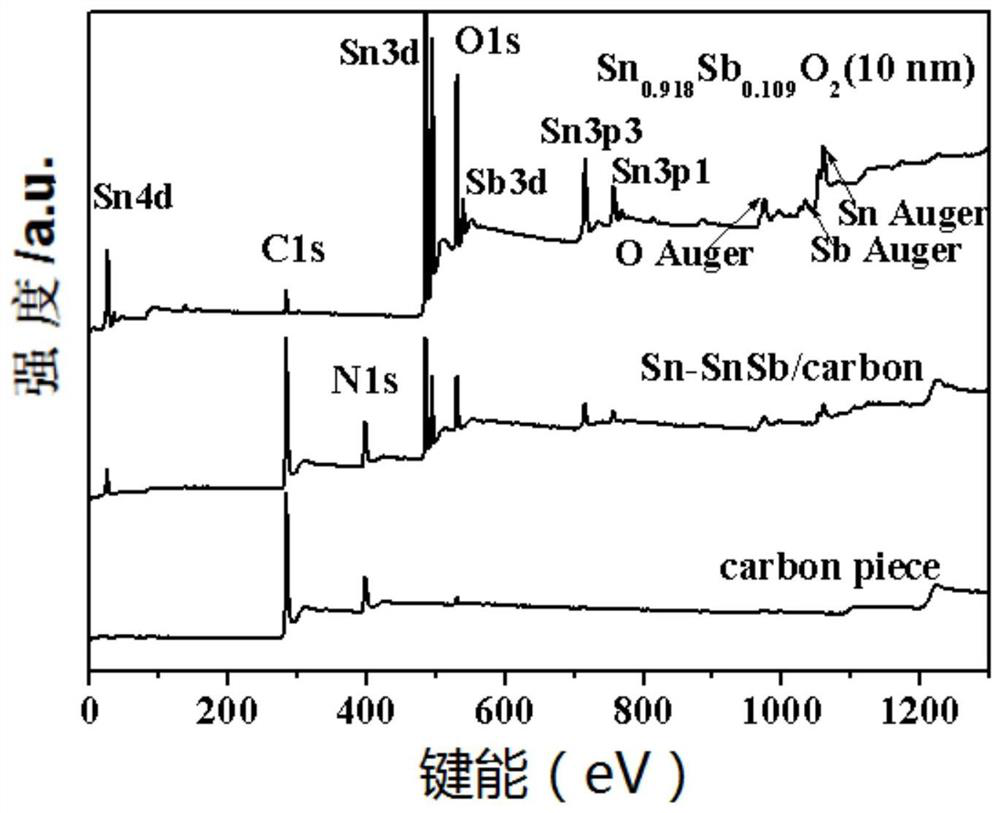

[0028] A preparation method of Sn-SnSb / carbon nanosheet composite material, comprising the following steps:

[0029] 1) Prepare 100 mL of a mixed solution of absolute ethanol and water, and the volume ratio of water to ethanol is 9:1.

[0030] 2) Disperse 3g of urea in the above mixed solution, ultrasonically treat until completely dissolved, add 0.1g of tin antimony oxide powder particles with a diameter of about 10 nm (wherein the molar ratio of Sn:Sb is about 9 / 1) and ultrasonically After 20 minutes of treatment, add 0.3 g of glucose, and after the glucose is completely dissolved, remove the solvent by rotary evaporation, and then dry in vacuum to obtain the precursor powder;

[0031] 3) Put the above precursor powder into the tube furnace, raise the temperature to 600°C at a rate of 2°C / min under argon, keep it for two hours, and then increase the temperature to 800°C at a rate of 2°C / min, After two hours of heat preservation, the temperature was lowered to room temperatu...

Embodiment 2

[0035] A preparation method of Sn-SnSb / carbon nanosheet composite material, comprising the following steps:

[0036] 1) Prepare 150 mL of a mixed solution of absolute ethanol and water, and the volume ratio of water to ethanol is 10:1.

[0037] 2) Disperse 6 g of urea in the above mixed solution. After ultrasonic dissolution is complete, add 0.15 g of tin antimony oxide (Sn:Sb molar ratio is about 9 / 1) powder particles with a diameter of 100 nm, and ultrasonically for 20 minutes. Add 0.3 g of sucrose to ultrasonically dissolve completely, remove the solvent by rotary evaporation, and then prepare the precursor powder by vacuum drying;

[0038] 3) Put the above precursor powder into a tube furnace, raise the temperature to 600°C at a rate of 2°C / min under He gas, keep it for two hours, and then raise the temperature to 800°C at a rate of 2°C / min. After two hours of heat preservation, the temperature was lowered to room temperature, and black powder was obtained, which was the ...

Embodiment 3

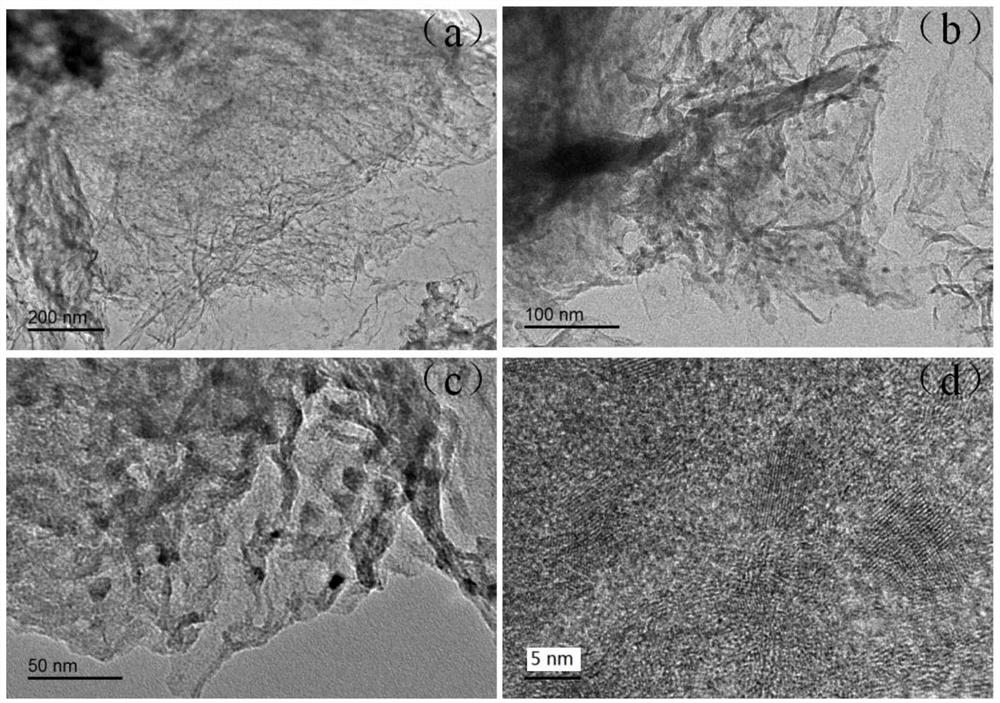

[0042] A preparation method of highly dispersed Sn-SnSb / carbon nano sheet composite material, comprising the following steps:

[0043] 1) Prepare 200 mL of a mixed solution of absolute ethanol and water, and the volume ratio of water to ethanol is 19:1.

[0044] 2) Disperse 6g of cyanoamine in the above mixed solution. After ultrasonic dissolution is complete, add 0.1g of tin antimony oxide (medium, Sn:Sb molar ratio is about 9 / 1) powder particles with a diameter of 30 nm, and ultrasonically 20 Minutes later, add 0.4 g of sucrose to ultrasonically dissolve completely, remove the solvent by rotary evaporation, and then prepare the precursor powder by vacuum drying;

[0045] 3) Put the above precursor powder into the tube furnace, under Ar / H 2 Raise the temperature to 600°C at a rate of 2°C / min under the mixed gas, keep it warm for two hours, then raise it to 800°C at a rate of 2°C / min, keep it at room temperature for two hours, and obtain a black powder, which is Carbon nanoshe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com