Vibrator with hollow structure and manufacturing method thereof

A manufacturing method and vibrator technology, which are applied in the structural form of the radiating element, the antenna support/installation device, etc., can solve the problems of high processing cost and the structure has not undergone more thorough changes, so as to reduce the weight of the vibrator, avoid processing pollution, The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

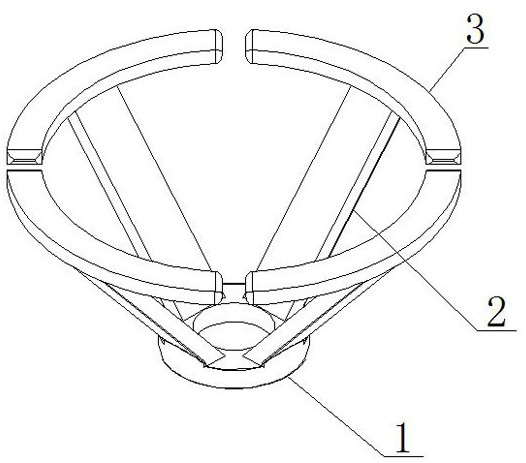

[0031] Such as figure 1 As shown, a vibrator with a hollow structure, the inside of the vibrator is a hollow structure. The vibrator with a hollow structure includes a vibrator base 1, a vibrator balun 2 and a vibrator radiating arm 3. The vibrator balun 2 is set obliquely to the plane where the vibrator base 1 is located and one end of the vibrator balun 2 is fixed on the upper side of the vibrator base 1. The vibrator balun 2 The hollow cavity of the vibrator base 1 communicates with the hollow cavity of the vibrator base 1. Several vibrator baluns 2 are distributed along the circumferential direction of the vibrator base 1. The vibrator radiation arm 3 is fixed at the other end of the vibrator balun 2. The hollow cavity of the vibrator balun 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com