A kind of poison canister of fire-fighting self-rescue respirator

A respirator and canister technology, applied in respiratory protection containers, breathing filters, life-saving equipment, etc., can solve problems such as inability to quickly and effectively remove harmful gases and smoke molecules, human discomfort, and damage to the human body. To facilitate the absorption, improve the contact effect, reduce the effect of toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

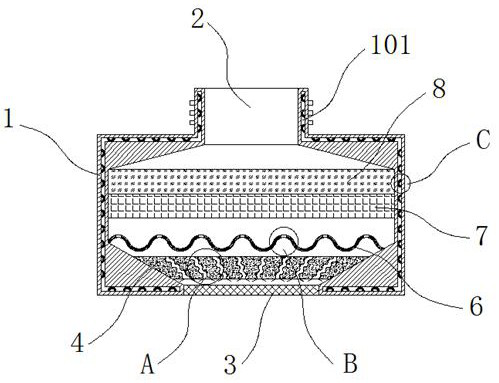

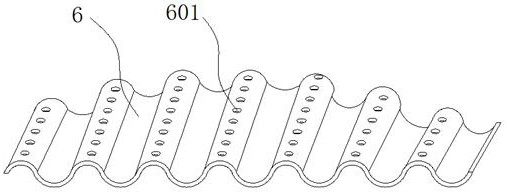

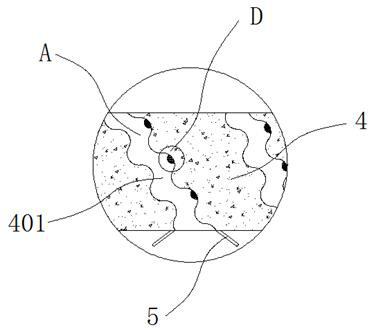

[0029] as attached figure 1 To attach Figure 7 Shown:

[0030] A canister for a fire-fighting self-rescue respirator, comprising: a shell 1, a hollow layer 101, a fixed block 102, a heat insulation layer 103, an air outlet 2, an air inlet 3, a filter layer 4, air holes 401, a smoking Block 402, inner groove 403, inclined plate 5, deodorizing layer 6, through hole 601, diversion groove 602, smoke filter layer 7 and drying layer 8; The inner side of housing 1 is embedded with hollow layer 101, and the inner side of hollow layer 101 The inner wall is fixedly connected with a fixed block 102, one side of the fixed block 102 is fixedly connected with a heat insulating layer 103, the top of the housing 1 is provided with an air outlet 2, the bottom of the housing 1 is provided with an air inlet 3, and the inner wall of the housing 1 The bottom is fixedly connected with a poison filter layer 4, and the surface of the poison filter layer 4 is connected with a ventilation hole 401, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com