Novel heat insulation patch applied to supersonic missile

A supersonic and patch technology, which is applied to ammunition, cartridge ammunition, self-propelled ammunition, etc., can solve the problems of low-density characteristic materials such as high temperature and inconspicuous heat insulation effect, and achieve good mechanical properties, simple manufacturing process, and insulation The effect that the heat effect is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

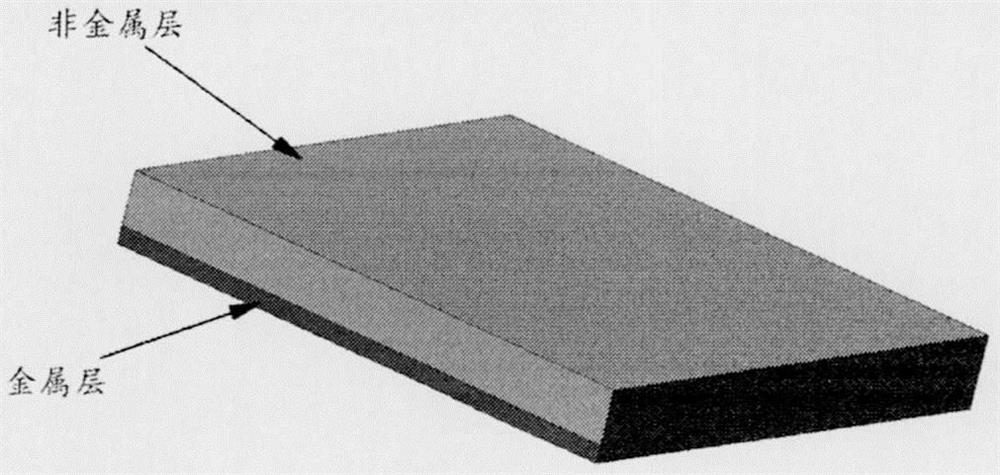

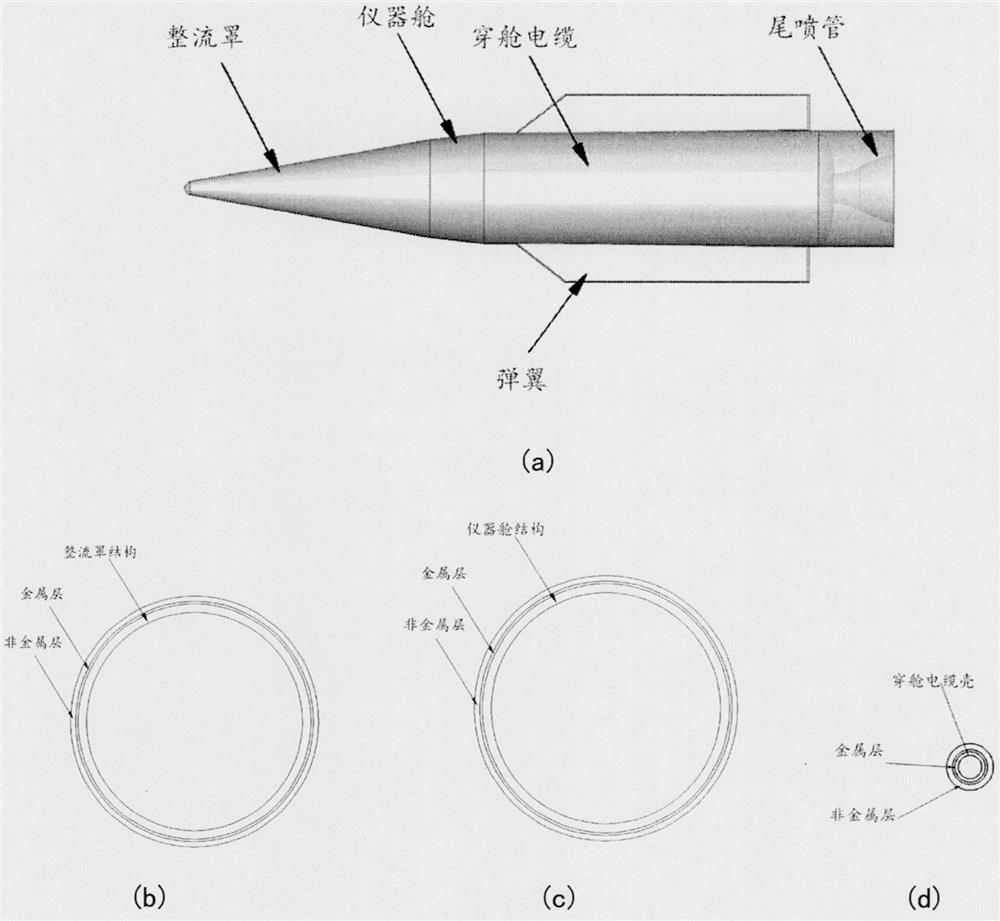

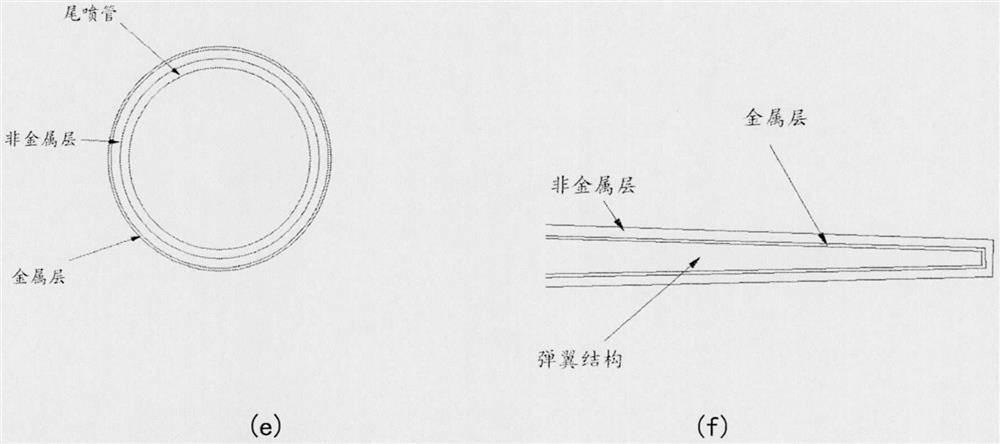

[0015] A new type of heat insulation patch applied to supersonic missiles, the main features are: low thermal conductivity non-metal + high-density metal double-layer structure, and glued by high-temperature-resistant adhesive, see figure 1 .

[0016] Based on the requirements of better ablation resistance and heat insulation, suitable non-metallic materials are selected. In addition, non-metallic materials should also meet the characteristics of low density and low material quality. The non-metallic materials used in this patch are: carbon fiber composite material, ablation-resistant silicone rubber, and cork. Considering the wide range of sources and low cost, the metal materials used in this patch are: alloy aluminum and alloy steel. This patch is glued with XZ-T002 and ZS-1071 type adhesives. Related material properties Table 1.

[0017] Table 1 Properties of metal materials and non-metal materials used in the patch

[0018]

[0019] The principle of patch heat insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com